Hydrogen sulfide tail gas treatment system and method

A technology for tail gas treatment and hydrogen sulfide, which is applied in chemical instruments and methods, separation methods, sulfur preparation/purification, etc., can solve the problems of polluted atmosphere, unstable treatment effect, low utilization value of alkali sulfide, etc., and achieves great economic significance. , The effect of processing the effect is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

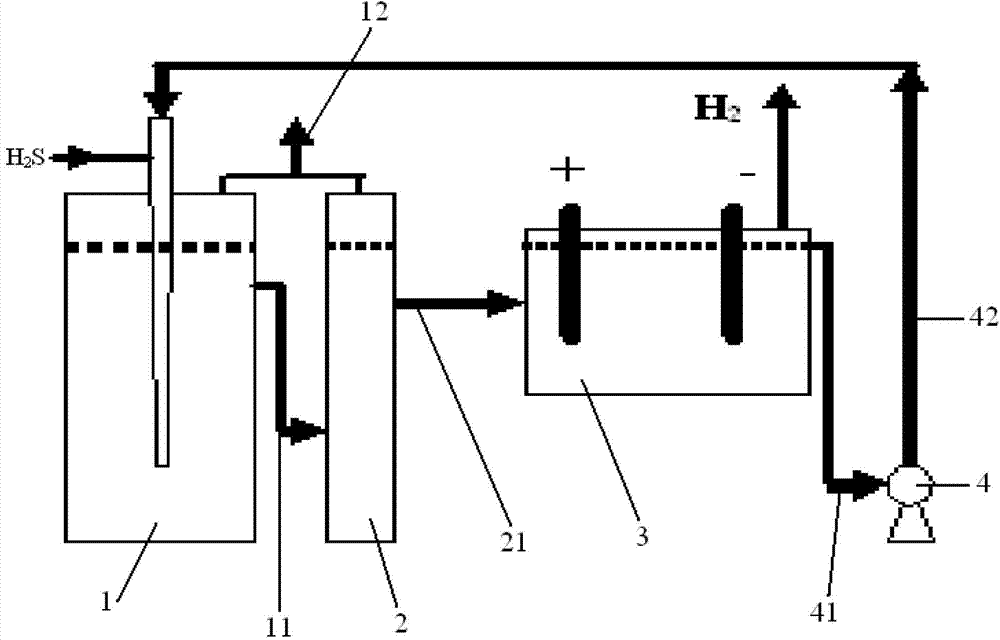

[0017] A hydrogen sulfide tail gas treatment system, comprising an absorption tank 1, a settling tank 2, an electrolytic tank 3 and a sequential pump 4; the hydrogen sulfide tail gas is transported to the absorption tank 1, and Fe 3+ Aqueous solution; the upper part of the side wall of the absorption tank 1 is provided with a first overflow pipe 11, and the overflow pipe 11 is communicated with the settling tank 2, and the tops of the absorption tank 1 and the settling tank 2 are all provided with a tail gas discharge pipe 12; The upper part of the side wall of the settling tank 2 is provided with a second overflow pipe 21, and the overflow pipe 21 communicates with the electrolytic tank 3; the inlet end of the circulation pump 4 communicates with the electrolytic tank 3 through the first pipeline 41, and the circulation The outlet end of the pump 4 is connected to the absorption pool 1 through the second pipe 42 .

[0018] The method for utilizing the above-mentioned system t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com