Heterogeneous catalyst, preparation method of heterogeneous catalyst and application of heterogeneous catalyst

A heterogeneous catalyst, catalyst technology, applied in oxidation reaction preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of long process cycle, unsatisfactory metal dispersion, cumbersome synthesis process, etc. The selectivity, preparation and processing operations are simple and easy, and the effect of high-efficiency transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

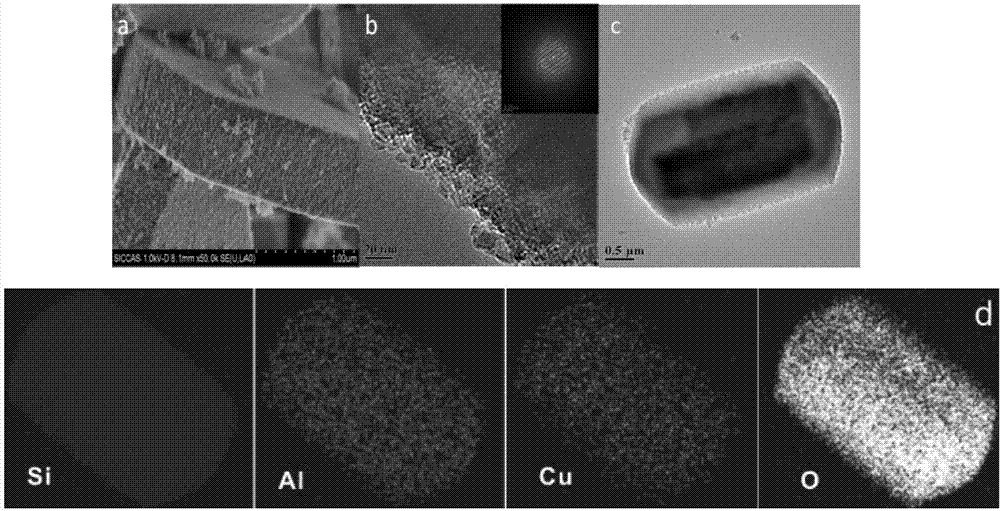

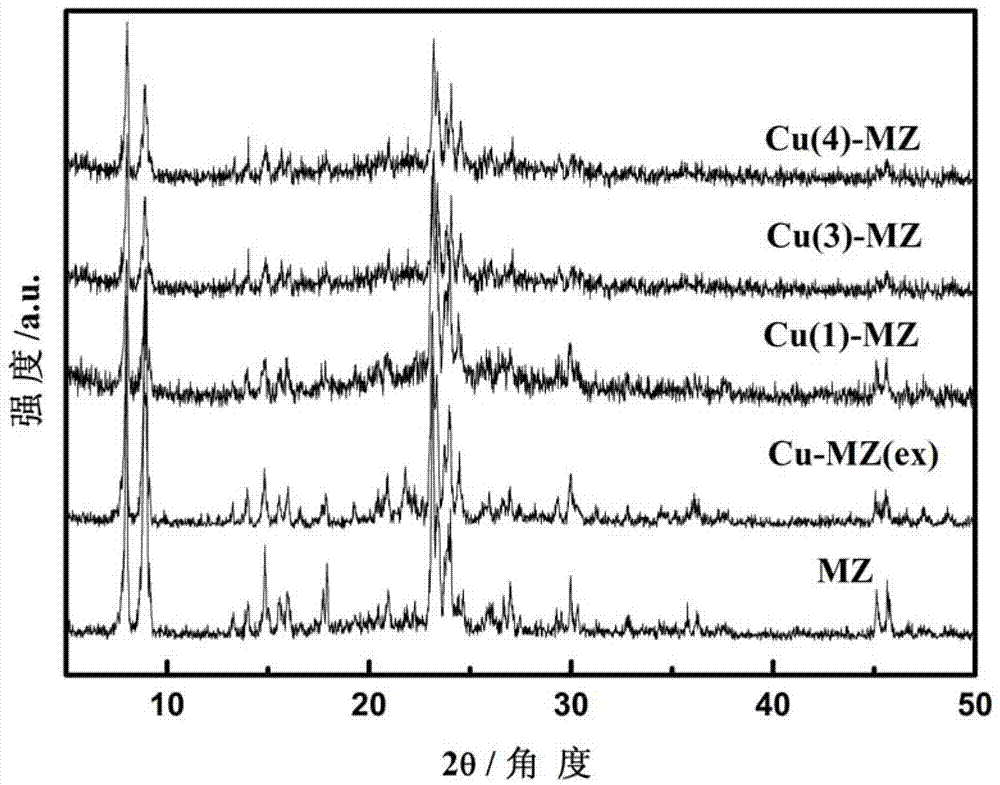

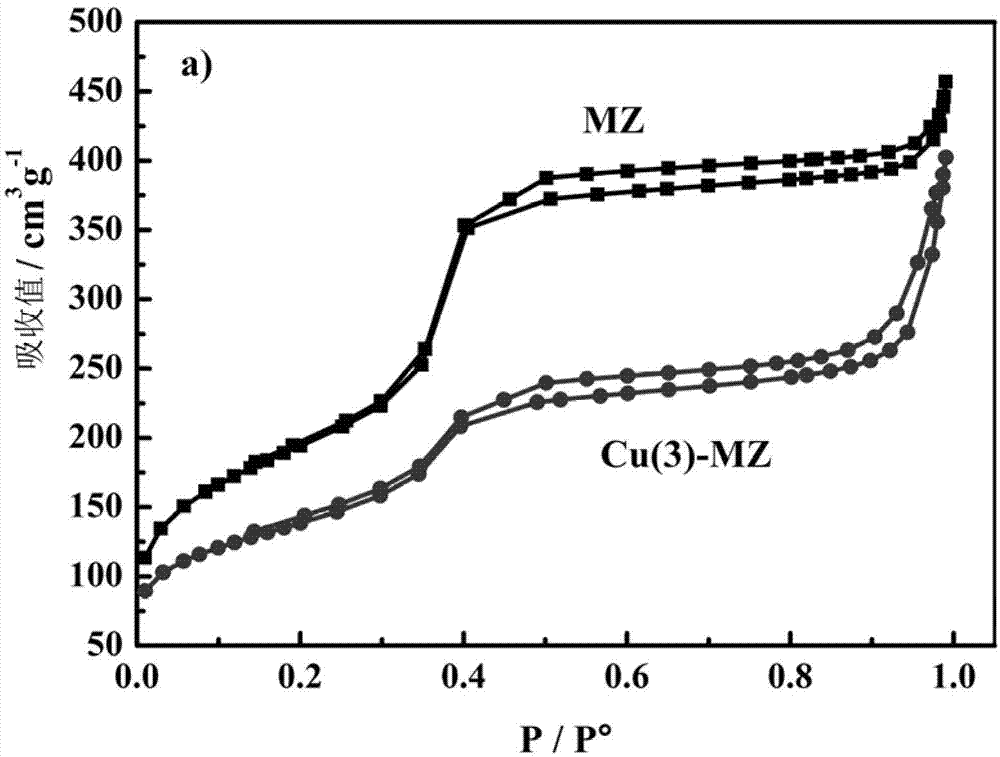

[0038] 0.009moL tetrapropylammonium hydroxide (TPAOH), 0.001mol triisopropoxyaluminum (Al( i PrO) 3 ) and 0.05molL tetraethyl orthosilicate (TEOS) and 0.003mol copper nitrate were added to 90mL water, stirred at a temperature lower than 15°C until the copper nitrate was completely dissolved, then aged at 5°C for 24 hours, and then the mixed aqueous solution was added to into 60 mL of surfactant cetyltrimethylammonium bromide (CTAB) aqueous solution with a concentration of 0.004 mol / L, stirred vigorously at 10°C for 3 hours, and aged at room temperature for 4 hours, and then the formed condensate Put the glue into a polytetrafluoroethylene hydrothermal kettle, carry out hydrothermal crystallization reaction at 150°C for 24 hours, centrifuge, wash the sample, dry at 100°C overnight, and finally roast at 550°C for 8 hours to remove inorganic salts and organic matter, and obtain The hierarchically porous zeolite material (Si / Al=50, Cu / Al=3) doped with Cu ions, that is, the hetero...

Embodiment 2

[0044] The difference between this embodiment and embodiment 1 is only that the molar amount of copper nitrate is 0.001 mol, and other contents are the same as those described in embodiment 1.

[0045] It was detected that the transition metal ions in the heterogeneous catalyst Cu(1)-MZ (Si / Al=50, Cu / Al=1) prepared in this example were basically loaded into the framework of the zeolite.

Embodiment 3

[0047] The difference between this embodiment and embodiment 1 is that the molar amount of copper nitrate is 0.002 mol, and other contents are the same as those described in embodiment 1.

[0048] It was detected that the transition metal ions in the heterogeneous catalyst Cu(2)-MZ (Si / Al=50, Cu / Al=2) prepared in this example were basically loaded into the framework of the zeolite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com