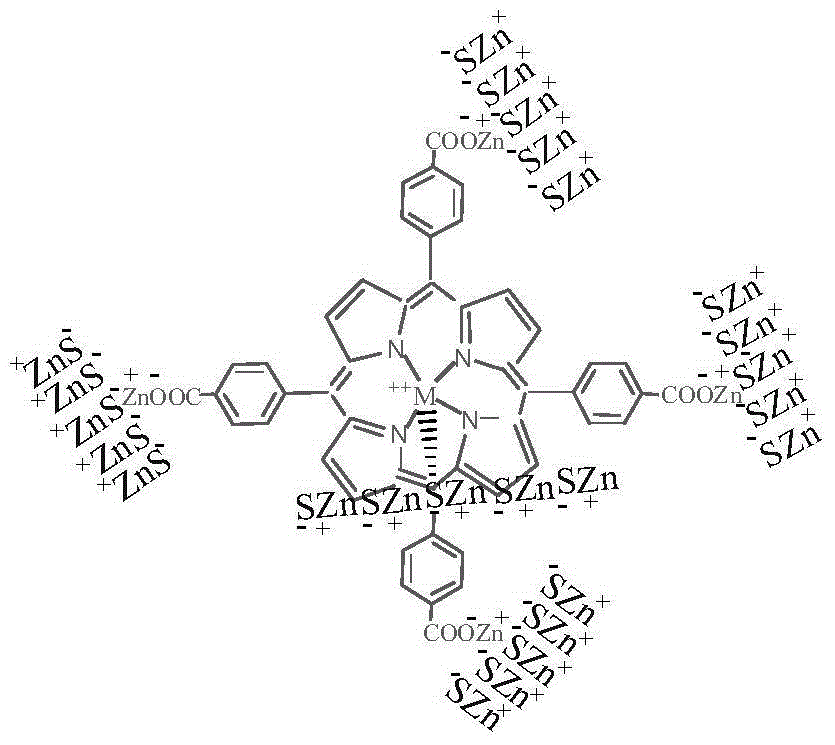

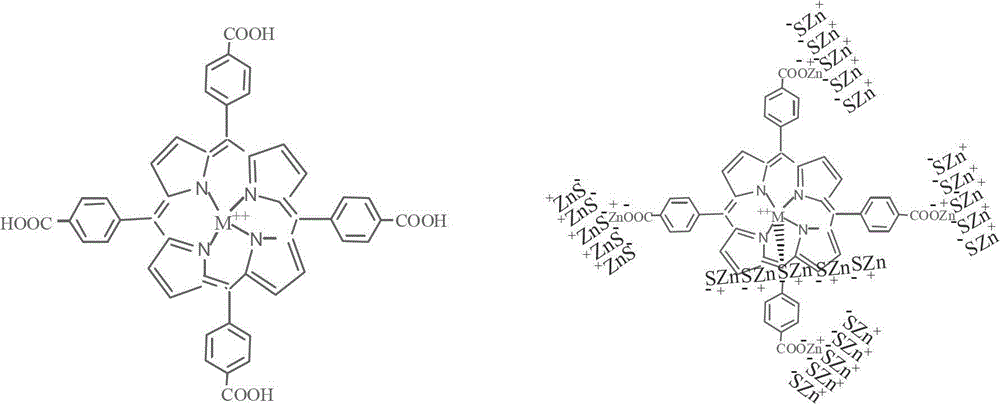

A kind of nano zinc sulfide metal porphyrin catalyst and its preparation method and application

A nano-zinc sulfide and metalloporphyrin technology, applied in the field of chemical engineering, can solve the problems of low conversion rate, low ketone alcohol yield and the like, and achieve the effects of improved catalytic performance, easy separation, and improved single-pass conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of zinc sulfide

[0032] Add 73.7666g of zinc sulfate heptahydrate into the dissolver, add 200g of deionized water and stir to completely dissolve it. After dissolving 61.6124g of sodium sulfide nonahydrate completely in the same way, slowly add to the dissolved ZnSO 4 In the solution, a white zinc sulfide precipitate is gradually formed, and it is filtered under reduced pressure, and the filter cake is washed with a large amount of deionized water, and at the same time, it is washed with BaCl 2 Solution tracking and detection of filtrate until there is no SO in the filtrate 4 2- ion.

[0033] 2. Preparation of nano-zinc sulfide cobalt porphyrin catalyst

[0034] The zinc sulfide obtained above was dispersed in 39g of ethanol by mechanical stirring, then 0.025g of cobalt porphyrin dissolved in 52g of ethanol was added, kept at 60°C and stirred for 6h, the organic solvent was removed by vacuum distillation, and the filter cake was filtered and washed. ...

Embodiment 2

[0040] 1. Preparation of zinc sulfide

[0041] Add 73.7666g of zinc sulfate heptahydrate into the dissolver, add 200g of deionized water and stir to completely dissolve it. After dissolving 61.6124g of sodium sulfide nonahydrate completely in the same way, slowly add to the dissolved ZnSO 4 In the solution, a white zinc sulfide precipitate is gradually formed, and it is filtered under reduced pressure, and the filter cake is washed with a large amount of deionized water, and at the same time, it is washed with BaCl 2 Solution tracking and detection of filtrate until there is no SO in the filtrate 4 2- ion.

[0042] 2. Preparation of nano-zinc sulfide cobalt porphyrin catalyst

[0043] The zinc sulfide obtained above was dispersed in 39g of ethanol by mechanical stirring, then 0.025g of cobalt porphyrin dissolved in 52g of ethanol was added, kept at 70°C and stirred for 5h, the organic solvent was removed by vacuum distillation, and the filter cake was filtered and washed. ...

Embodiment 3

[0049] 1. Preparation of zinc sulfide

[0050] Add 73.7666g of zinc sulfate heptahydrate into the dissolver, add 200g of deionized water and stir to completely dissolve it. After dissolving 61.6124g of sodium sulfide nonahydrate completely in the same way, slowly add to the dissolved ZnSO 4 In the solution, a white zinc sulfide precipitate is gradually formed, and it is filtered under reduced pressure, and the filter cake is washed with a large amount of deionized water, and at the same time, it is washed with BaCl 2 Solution tracking and detection of filtrate until there is no SO in the filtrate 4 2- ion.

[0051] 2. Preparation of nano-zinc sulfide cobalt porphyrin catalyst

[0052] The zinc sulfide obtained above was dispersed in 39g of methanol by mechanical stirring, and then 0.025g of cobalt porphyrin dissolved in 52g of methanol was added, kept at 65°C and stirred for 5.5h, and the organic solvent was removed by vacuum distillation, and filtered, washed and filtered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com