Preparation method for porous biomimetic catalytic material and application thereof

A biomimetic catalysis and pore-shaped technology, applied in the field of chemical engineering, can solve the problems of low single-pass conversion rate, low selectivity, and large pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

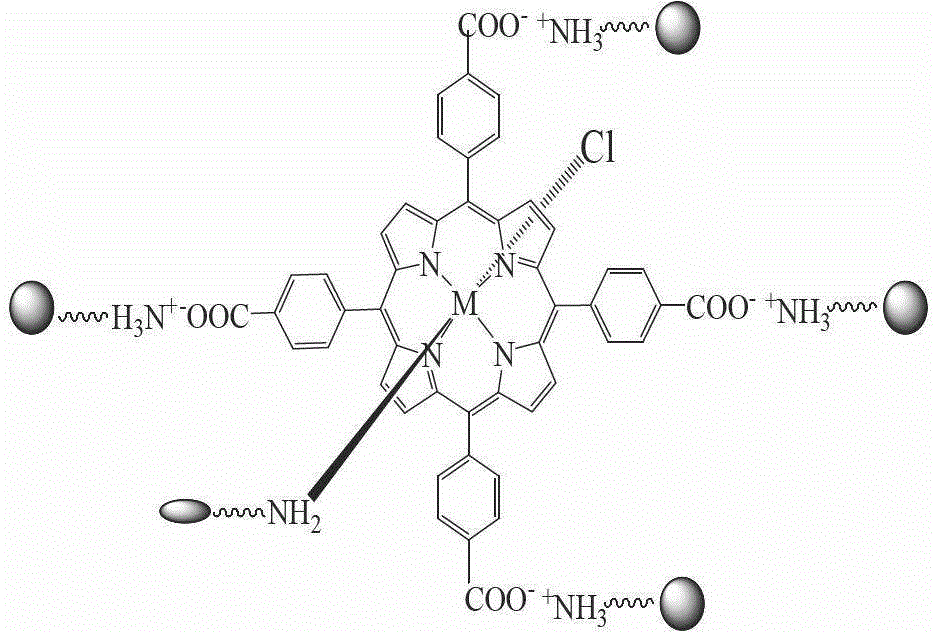

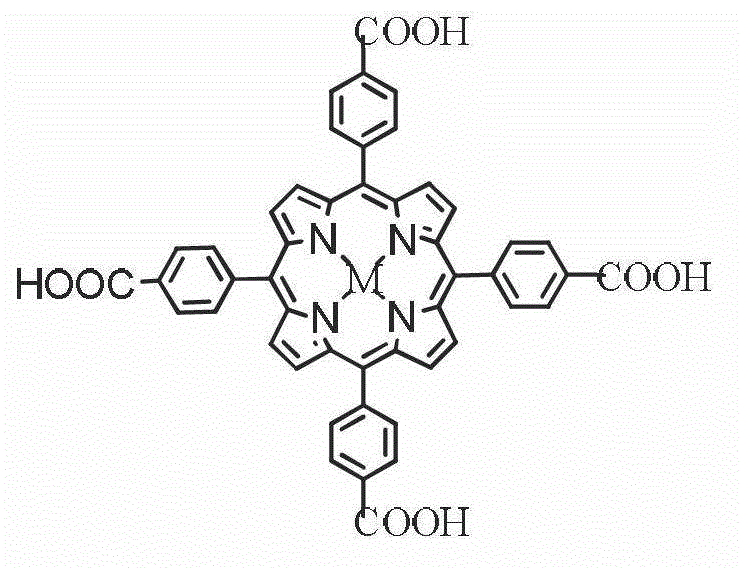

[0036] 1. Preparation of porous biomimetic catalytic material-tetrakis(p-carboxyphenyl)metal cobalt porphyrin

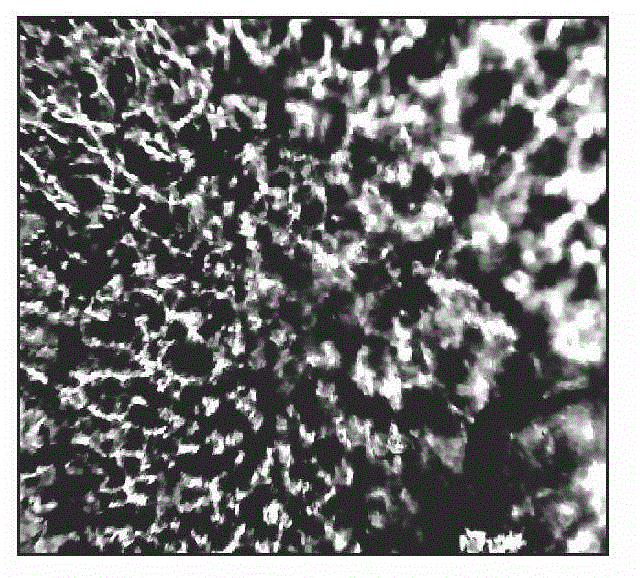

[0037] Weigh 34g of chitosan and dissolve it in 600ml of 2% acetic acid solution, and mechanically stir until colloidal. Add 200ml of 4% ammonia water drop by drop under stirring until the pH of the solution is 7 to form a viscous colloid. Slowly add 100ml 0.28g / L tetrakis(p-carboxyphenyl)cobalt porphyrin ethanol solution through the dropping funnel, after stirring for 24h, obtain red colloid by suction filtration, add 80g NH 4 HCO 3 , stirred until uniform, dried under an infrared lamp at 56°C, and then vacuum-dried at a controlled temperature of 56°C, a vacuum degree of 0.007MPa, and a time of 6h to prepare a porous biomimetic catalytic material - tetrakis (p-carboxyphenyl) metal cobalt porphyrin . Its real state diagram is shown in Fig.

[0038] 2. Application of porous biomimetic catalytic material - tetrakis (p-carboxyphenyl) metal cobalt porphyrin

[0039]...

Embodiment 2

[0049] Porous Biomimetic Catalytic Material-Recycling of Tetra(p-Carboxyphenyl)Metal Cobalt Porphyrin

[0050] Put the porous biomimetic catalytic material loaded with 1.0mg tetrakis(p-carboxyphenyl)cobalt porphyrin equivalent into a 500ml reaction kettle, add 200ml cyclohexane, the reaction temperature is 160°C, the air pressure is 0.9MPa, and the stirring speed is 150 revolutions per minute, when the reaction time is 3.5h, the air flow rate is 0.03m 3 / h, the conversion rate of cyclohexane is 16.29%, the selectivity of ketone alcohol is 72.09%, and the catalyst conversion number is 2.45×10 5 , The yield of ketone alcohol is 11.74%. After stopping the catalytic reaction each time, wait for the catalytic material to separate from the reaction mixture through natural sedimentation, filter, wash with ethanol, and then dry naturally to recover the catalytic material, and then use it to catalyze the air oxidation of cyclohexane under the same reaction conditions. Such reutilizat...

Embodiment 3

[0052] 1. Preparation of porous biomimetic catalytic material-tetrakis(p-carboxyphenyl)metallomanganese porphyrin

[0053] The chitosan that takes by weighing 34g is dissolved in the acetic acid solution of 600ml 2%, obtains colloid with mechanical stirring. Under high-speed stirring, add 200ml of 4% ammonia water drop by drop to pH = 6.5 to form a viscous colloid. Slowly add 100ml of 0.28g / L ethanol solution of tetrakis(p-carboxyphenyl)manganese porphyrin through the dropping funnel, stir vigorously for 24h, obtain bright yellow colloid by suction filtration, add 80g of NH 4 HCO 3 , stirred until uniform, dried under an infrared lamp (60°C), then vacuum-dried at a temperature of 60°C, a vacuum degree of 0.010MPa, and a time of 7h to prepare a porous biomimetic catalytic material - tetrakis (p-carboxyphenyl) metal manganese porphyrin.

[0054] 2. Application of porous biomimetic catalytic material - tetrakis(p-carboxyphenyl) manganese metal porphyrin

[0055] (1) Put the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com