Porous chitosan metal porphyrin composite and preparation method and application thereof

A metalloporphyrin and chitosan technology, applied in the field of chemical engineering, can solve the problems of low reusability per unit mass of metalloporphyrin, low single-pass conversion rate, low selectivity, etc., so as to improve the single-pass conversion rate and reduce the dosage. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

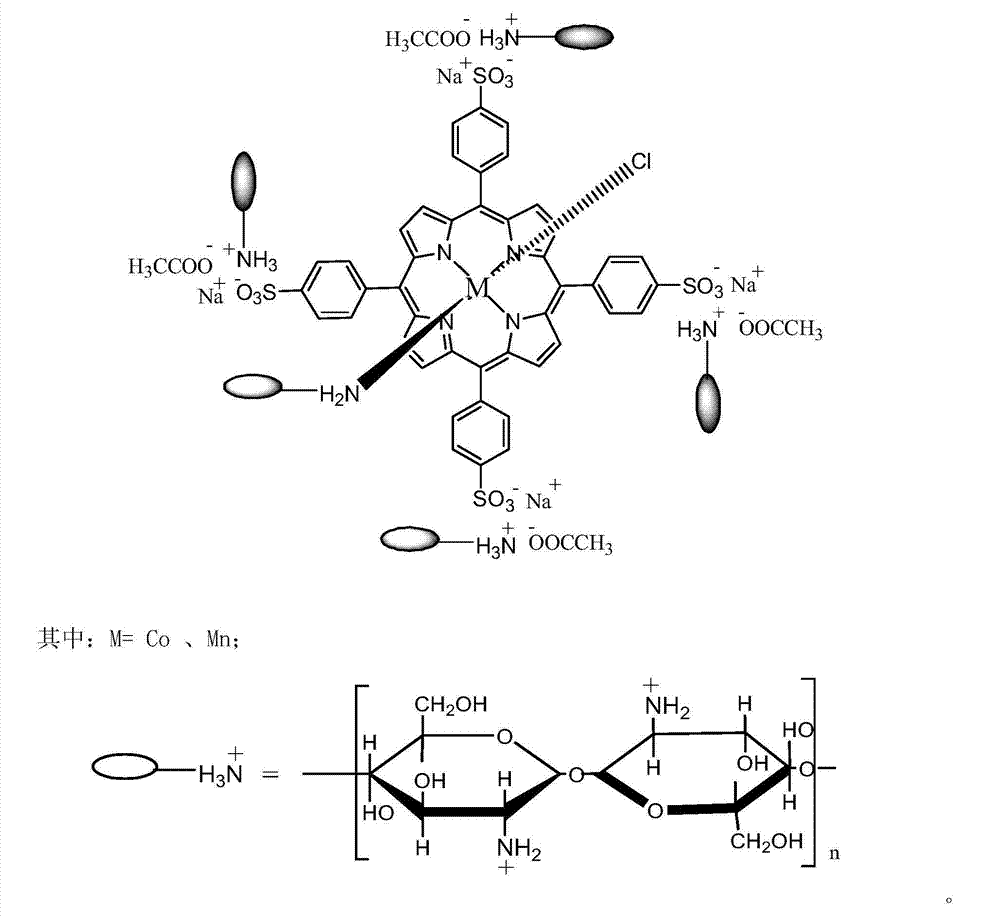

[0033] Preparation of porous chitosan four (sodium p-sulfonate) phenyl cobalt porphyrin complex:

[0034] Weigh 40 g of chitosan and dissolve it in 200 ml of 2% acetic acid solution, and mechanically stir until it becomes a yellow colloidal liquid. Add 213ml of ammonia water with a concentration of 11% dropwise under stirring to adjust the solution to pH=6.5 to form white flocs. Slowly add 100ml of tetrakis(sodium p-sulfonate)phenylcobalt porphyrin aqueous solution with a concentration of 0.4g / L through the dropping funnel, after stirring for 24 h, suction filter to obtain a paste-like colloid, add 100g NH 4 HCO 3 , stirred until uniform, dried under an infrared lamp, and vacuum-dried to prepare a porous chitosan tetrakis(sodium p-sulfonate) phenyl cobalt porphyrin complex.

Embodiment 2

[0036] Preparation of porous chitosan / tetrakis(sodium p-sulfonate)phenyl manganese porphyrin complex:

[0037] Weigh 40 g of chitosan and dissolve it in 200 ml of 2% acetic acid solution, and mechanically stir until it becomes a yellow colloidal liquid. Under high-speed stirring, 213ml of 11% ammonia water was added dropwise to pH=7. Slowly add 100ml of 0.4g / L aqueous solution of tetrakis(sodium p-sulfonate)phenylmanganese porphyrin through the dropping funnel, stir vigorously for 24 h, filter with suction, dry under infrared light, add 100g of NH 4 HCO 3 , made porous chitosan tetrakis (sodium p-sulfonate) phenyl manganese porphyrin complex by vacuum drying 。

Embodiment 3

[0039] Preparation of porous chitosan four (sodium p-sulfonate) phenyl manganese porphyrin complex:

[0040] First add 8.78 kg of glacial acetic acid and 439 kg of deionized water in the reaction vessel to make an aqueous acetic acid solution, add 17.6 kg of powdered chitosan, start the stirrer, and stir for several hours at a high speed greater than 2500 rpm, until it is completely After dissolving, the material is discharged to obtain a yellow colloidal liquid, and then 103.03 parts of deionized water are added to the reactor; under stirring, ammonia water is added drop by drop until the pH of the solution is 6.5, and white flocs are precipitated from the solution; 100ml 0.4g / L tetrakis (sodium p-sulfonate) phenyl manganese porphyrin aqueous solution, under stirring chitosan and tetrakis (sodium p-sulfonate) phenyl manganese porphyrin carry out acid-base reaction and coordination at room temperature Reaction, reaction time 24 h, the obtained chitosan tetrakis (sodium p-sulfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com