Double-circulation jetting type heavy metal removing method and device

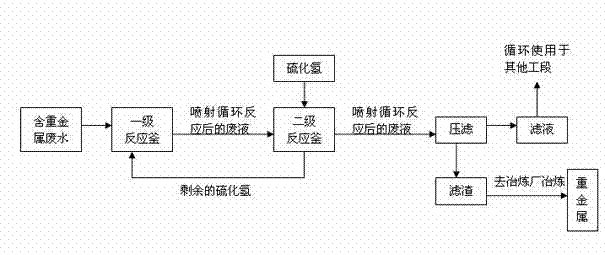

A spray-type, heavy metal technology, which is applied in chemical instruments and methods, metallurgical wastewater treatment, water/sewage multi-stage treatment, etc., can solve the problems of heavy metal sulfide removal, non-recyclable resources, hydrogen sulfide pollution and other problems. Achieve the effect of low cost, convenient management and high removal rate of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

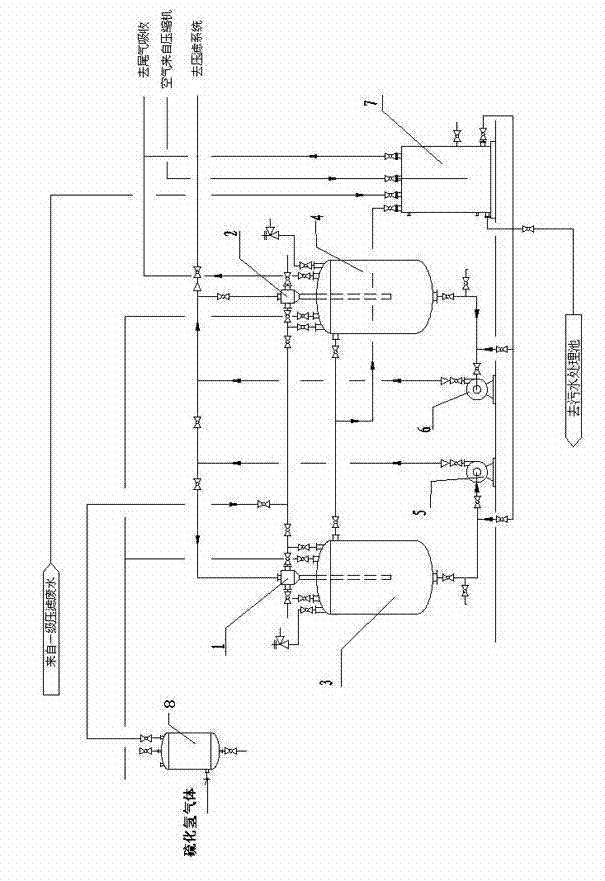

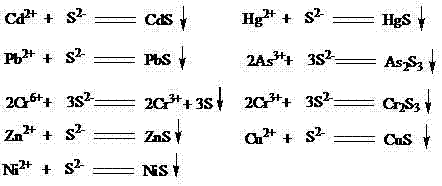

Method used

Image

Examples

Embodiment 1

[0018] Take 1 cubic meter of wastewater (the wastewater is arsenic-containing wastewater from a sulfuric acid plant, with an acid content of 2.53% and an arsenic content of 1.15%), and use a double-cycle jetting type heavy metal removal device with a cycle temperature of 40°C, a cycle time of 60 minutes, and a reaction pressure of 0.2 MPa. After the reaction, the arsenic content was 0.0002% (2ppm), the arsenic removal rate reached 99.98%, and 22.62Kg of dry residue was obtained, and the arsenic content in the dry residue was 34.53%

Embodiment 2

[0020] Take 1 cubic meter of waste water (the waste water is arsenic-containing waste water from a sulfuric acid plant, the acid content is 2.53%, and the arsenic content is 2.29%), and a double-cycle jetting heavy metal removal device is used, with a cycle temperature of 40°C, a cycle time of 90 minutes, and a reaction pressure of 0.2 MPa. After the reaction, the arsenic content was 0.0004% (4ppm), the removal rate of arsenic reached 99.98%, and 39.71Kg of dry residue was obtained, and the arsenic content in the dry residue was 34.53%

Embodiment 3

[0022] Take 1 cubic meter of lead-acid battery wastewater (the total lead in the wastewater is 140.2mg / L, the total cadmium is 88.3mg / L, pH1.8), and a double-cycle jetting heavy metal removal device is used. The cycle temperature is 40°C and the cycle time is 90 minutes. The pressure is 0.2Mpa. After the reaction, the total lead content in the filtrate was 1.26mg / L, the total cadmium content was 0.44mg / L, the lead removal rate reached 99.1%, and the cadmium removal rate reached 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com