A kind of modified coconut shell activated carbon and its use in the preparation of pharmaceutical grade guanidine hydrochloride

A coconut shell activated carbon and modification technology, which is applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., can solve the problems of large solubility gap, different content, limited production capacity, etc., and achieve high removal rate, good The effect of decolorization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

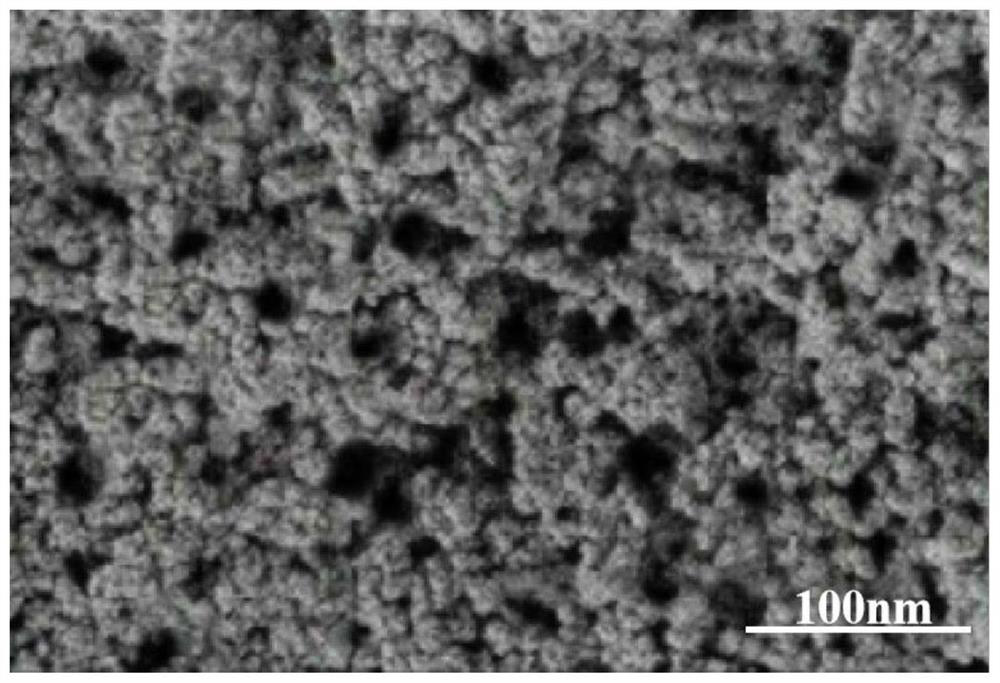

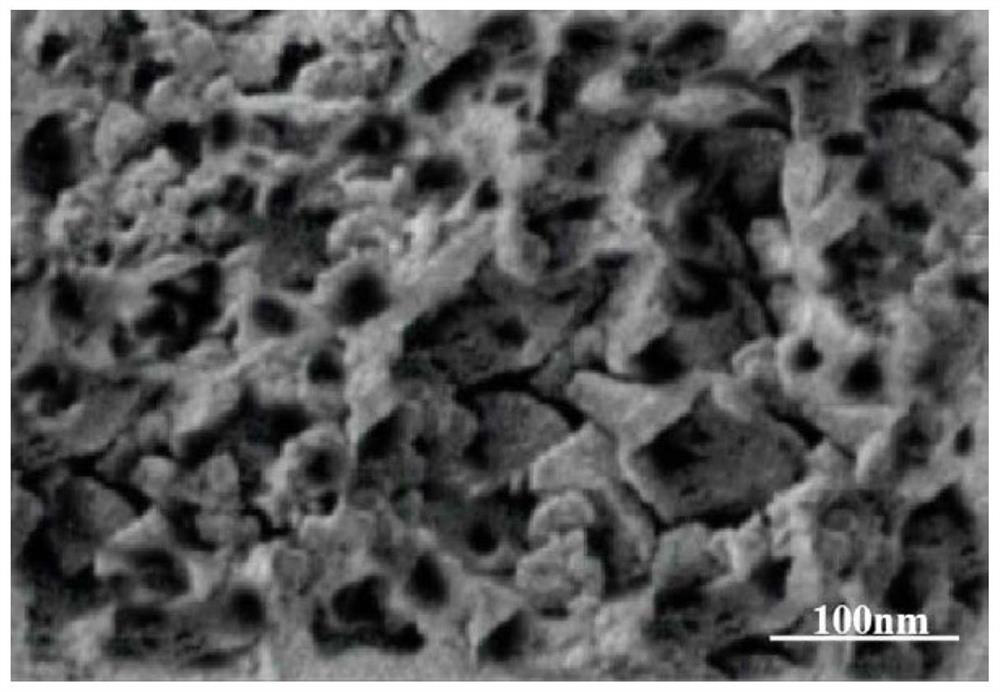

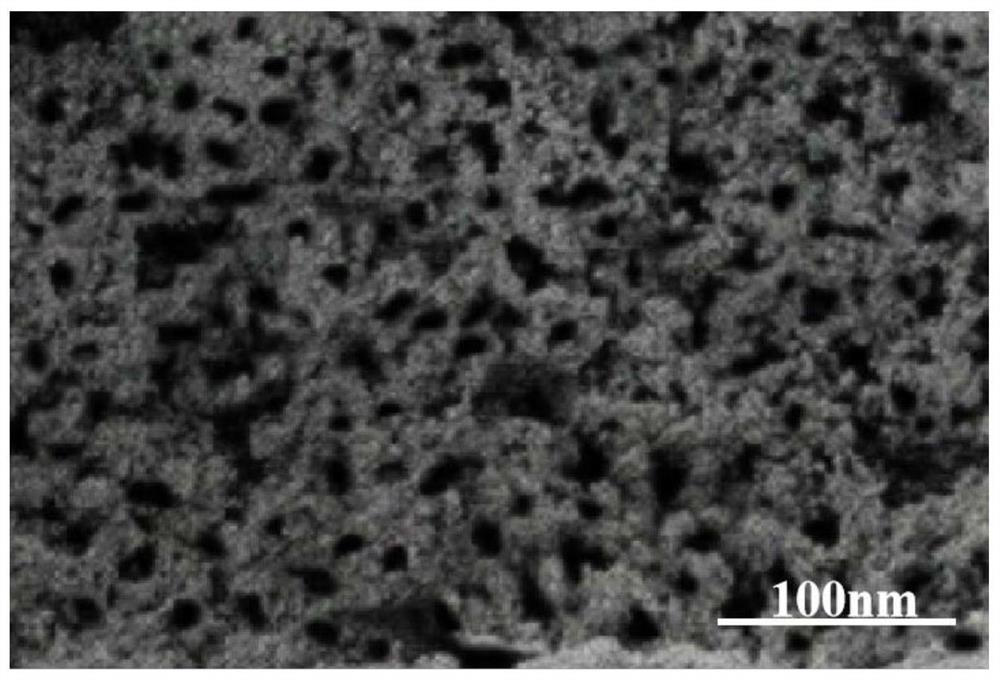

Image

Examples

preparation example Construction

[0033] Further, in some specific embodiments of the present invention, a kind of preparation method of modified coconut shell activated carbon, comprises:

[0034] Provide coconut shell raw materials, pulverize, sieve and dry the coconut shell raw materials to obtain pretreated coconut shell powder;

[0035] Mixing coconut shell powder with a phosphoric acid solution mixed with 27-hydroxyisomango alkyd, adding neohesperidin to the above solution, and soaking for 10 to 14 hours to obtain a soaking mixture;

[0036] The impregnated mixture is activated, cooled, washed, dried and ground in a muffle furnace to obtain modified coconut shell activated carbon.

[0037] Further, in some specific embodiments of the present invention, the molar ratio of neohesperidin to 27-hydroxyisomangiferic acid is 0.5-0.8:1.

Embodiment 1

[0039] A preparation method of modified coconut shell activated carbon, comprising:

[0040] Provide coconut shell raw materials, pulverize and sieve the coconut shell raw materials, select coconut shell powder with an average particle size of 15 meshes, and place it in a constant temperature blast drying oven at 105 ° C to dry for 14 hours to obtain pretreated coconut shell powder. body;

[0041] Phosphoric acid solution (45wt%) is mixed with above-mentioned coconut shell powder, wherein the ratio of phosphoric acid to coconut shell powder is 0.3mol:10g, then 27-hydroxyisomango alkyd is added thereto, stirring from time to time, and 27-hydroxyisomango alkyd is added thereto. The molar ratio of mango alkyd and phosphoric acid is 1:4, and the dipping mixture is obtained by dipping at room temperature for 12 hours;

[0042] The above impregnated mixture was placed in a muffle furnace for activation at 515°C for 3 hours, cooled to room temperature, washed with deionized water un...

Embodiment 2

[0044] A preparation method of modified coconut shell activated carbon, comprising:

[0045] Provide coconut shell raw materials, pulverize and sieve the coconut shell raw materials, select coconut shell powder with an average particle size of 10 meshes, and place it in a constant temperature blast drying oven at 110 ° C to dry for 12 hours to obtain pretreated coconut shell powder. body;

[0046] Phosphoric acid solution (40wt%) is mixed with above-mentioned coconut shell powder, wherein the ratio of phosphoric acid and coconut shell powder is 0.2mol:10g, then add 27-hydroxyisomango alkyd to it, and stir from time to time, 27-hydroxyisomango alkyd The molar ratio of mango alkyd and phosphoric acid was 1:5, and the dipping mixture was obtained by dipping at room temperature for 14 hours;

[0047] The above impregnated mixture was placed in a muffle furnace for activation at 480 °C for 1 h, cooled to room temperature, washed with deionized water until the pH of the solution wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com