Method for disposing cyclohexanone saponified waste liquid

A technology for waste liquid treatment and cyclohexanone, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., and can solve problems such as non-recyclable treatment, large environmental pollution, and environmental pollution , achieving significant economic benefits, less energy consumption, and pollution control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

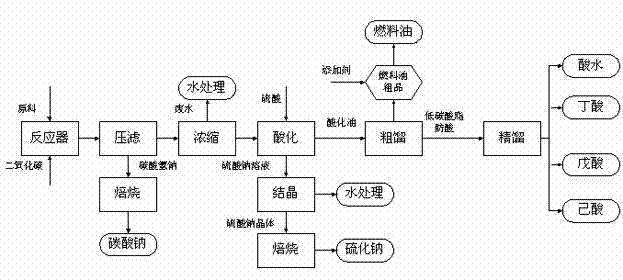

[0021] A kind of cyclohexanone saponification waste liquid treatment method, reaction technological process is as figure 1 As shown, it includes the following steps:

[0022] (1) first pass into carbon dioxide gas in the cyclohexanone saponification waste liquid, after the reaction finishes, waste liquid is input to the filter press filter press, obtain sodium bicarbonate solid and press filter liquid; The temperature of described reaction is 250- 300°C, the reaction pressure is 5-6 atmospheres.

[0023] (2) Get step (1) press filter liquid and carry out MVR evaporator concentration or multi-effect evaporation concentration, obtain concentrate, input in the sulfuric acid reactor, then add sulfuric acid in reactor and carry out acidification, make the concentration of sulfuric acid be 35%~ 45%, to obtain sodium sulfate solution and acidified oil, the sodium sulfate solution is concentrated and crystallized to obtain sodium sulfate solid;

[0024] (3) taking the acidified oi...

Embodiment 2

[0028] Get respectively 600 milliliters of the treatment liquid after the multi-tower rectification separation of butyric acid, hexanoic acid and valeric acid and the original cyclohexanone saponification waste liquid in Example 1, and then detect the COD value respectively. The experimental results show that after the process of the present invention, The COD value of the processed liquid is 18210 mg / L, and the COD value of the former cyclohexanone saponification waste liquid is 455290mg / L, and experimental result shows that the COD removal rate of the cyclohexanone saponification waste liquid treatment method provided by the present invention is 96.1% , can effectively treat saponification liquid wastewater, and has important social and economic effects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com