High amylase corn starch paste and preparation method thereof

A corn starch and high amylose technology, which is applied in the field of starch industrial processing, can solve the problems of weak structure and the quality of high amylose corn starch paste, and achieves the effects of convenient operation, simple and reliable preparation method, and cost saving of gelatinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

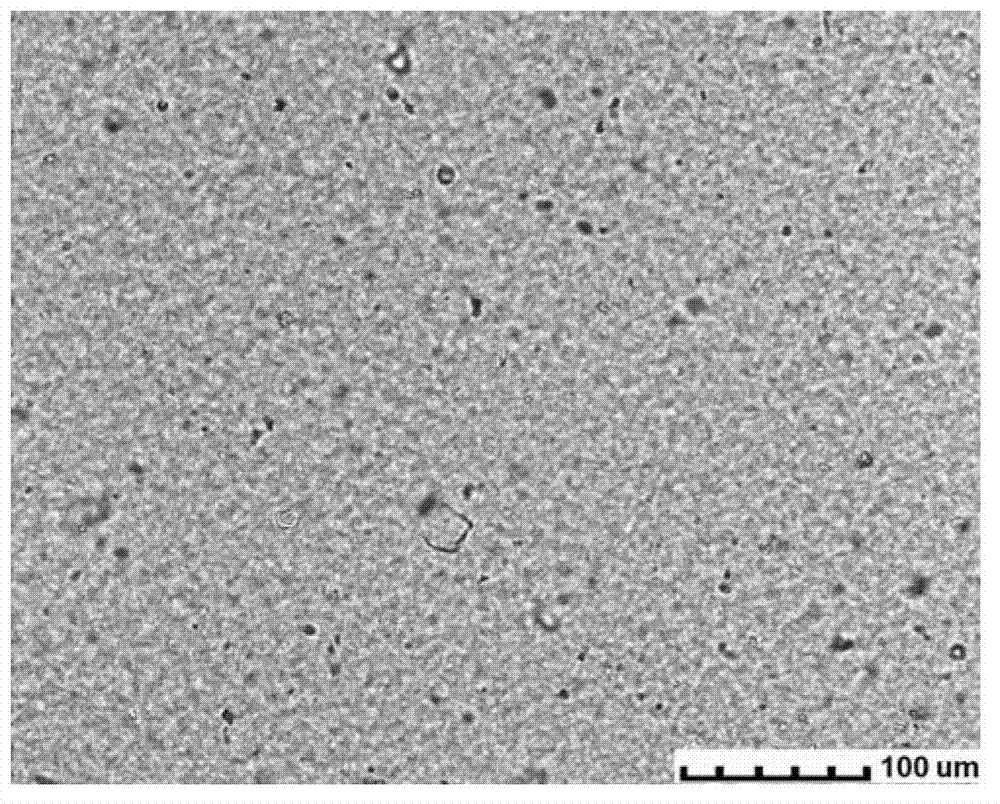

Embodiment 1

[0029] (1) Alkali treatment of starch suspension

[0030] Mix 4 g of high-amylose corn starch (dry basis) and 30 ml of deionized water in a beaker to obtain a high-amylose corn starch aqueous suspension, and gently stir to wet the starch granules, wherein the mass percentage of high-amylose corn starch is 12%. Then add 40ml of aqueous sodium hydroxide solution (concentration 1mol / L) into the high amylose corn starch aqueous suspension, and stir while adding to make the aqueous sodium hydroxide solution and the high amylose corn starch particles fully contact. The above-mentioned processes are all carried out at room temperature, and the temperatures of deionized water and lye are both at room temperature.

[0031] (2) Preparation of high amylose corn starch paste

[0032] Stir the mixture of high-amylose cornstarch and lye obtained in step (1) to fully gelatinize the high-amylose cornstarch at a stirring rate of 450rpm for 20min and a stirring blade radius of 2.5cm. After st...

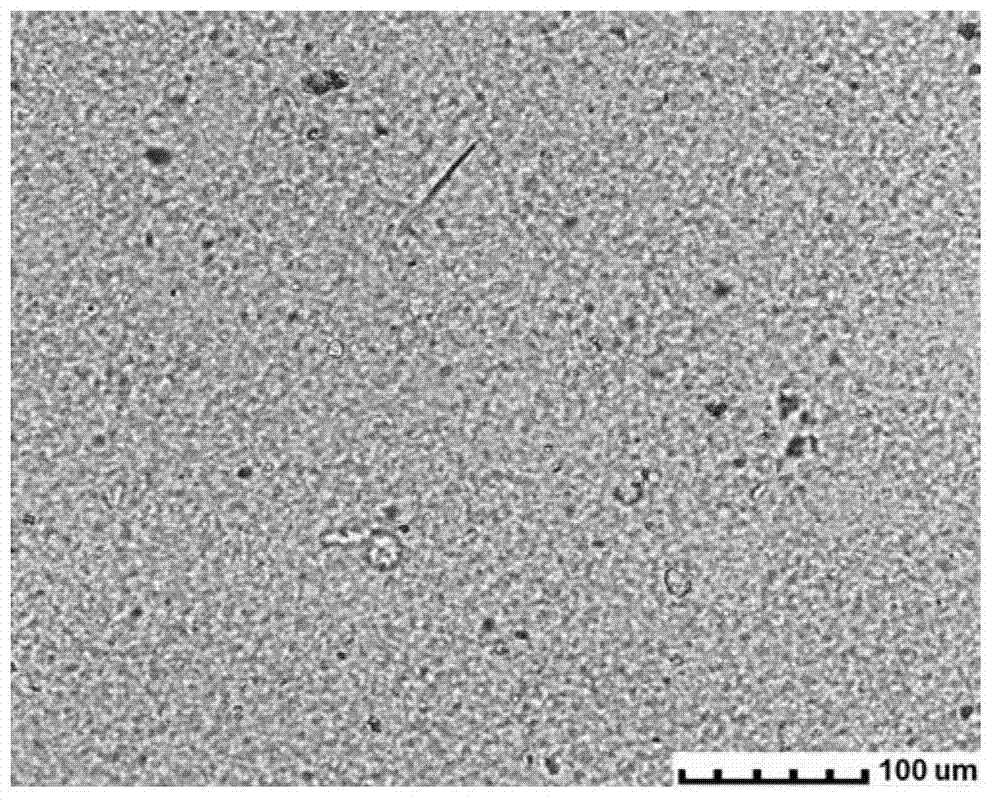

Embodiment 2

[0042] (1) Alkali treatment of starch suspension

[0043] Mix 4 g of high-amylose corn starch (dry basis) and 30 ml of deionized water in a beaker to obtain an aqueous suspension of high-amylose corn starch, and gently stir to moisten the starch granules, wherein the mass percentage of high-amylose corn starch is 12%. Then add 40ml of sodium hydroxide aqueous solution (concentration 1mol / L) into the high amylose corn starch aqueous suspension, and stir while adding to make the sodium hydroxide aqueous solution and the high amylose corn starch granules fully contact. The above-mentioned processes are all carried out at room temperature, and the temperatures of deionized water and lye are both at room temperature.

[0044] (2) Preparation of high amylose corn starch paste

[0045] Stir the mixture of high-amylose cornstarch and lye obtained in step (1) to fully gelatinize the high-amylose cornstarch at a stirring rate of 450rpm for 20min and a stirring blade radius of 2.5cm. A...

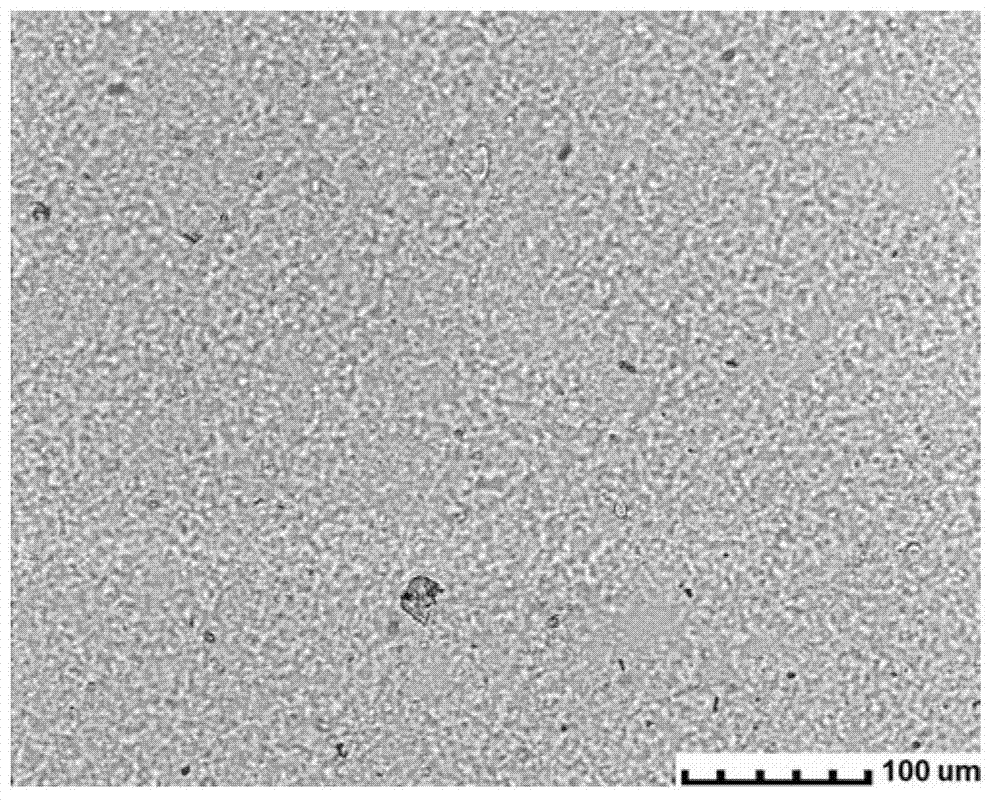

Embodiment 3

[0055] (1) Alkali treatment of starch suspension

[0056] Mix 4 g of high-amylose corn starch (dry basis) and 30 ml of deionized water in a beaker to obtain a high-amylose corn starch aqueous suspension, and gently stir to wet the starch granules, wherein the mass percentage of high-amylose corn starch is 12%. Then add 40ml of sodium hydroxide solution (concentration 1mol / L) into the starch suspension obtained above, and stir while adding to make the sodium hydroxide solution fully contact with the high-amylose corn starch granules. The above-mentioned processes are all carried out at room temperature, and the temperatures of deionized water and lye are both at room temperature.

[0057] (2) Preparation of high amylose corn starch paste

[0058] Stir the mixture of high-amylose cornstarch and lye obtained in step (1) to fully gelatinize the high-amylose cornstarch at a stirring rate of 450rpm for 20min and a stirring blade radius of 2.5cm. After the stirring, the pH value wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com