Terrace coating and preparation method thereof

A floor coating and resin technology, applied in the field of coatings, can solve the problems of concentrated reaction heat release, increased construction costs, poor color retention and UV resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

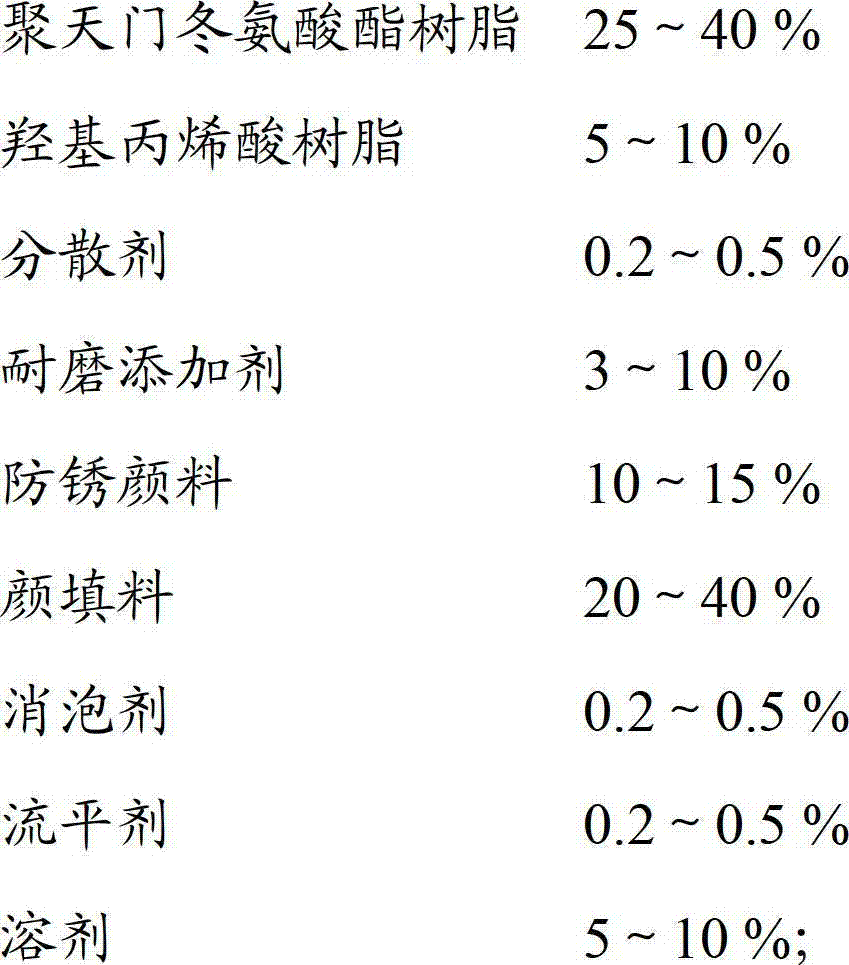

Method used

Image

Examples

preparation example Construction

[0032] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned floor paint with simple process, low cost, easy operation and control. This preparation method comprises the steps:

[0033] S01. Weigh each component according to the formula: weigh each component according to the formula of the above-mentioned floor paint;

[0034] S02. Prepare the mixture: mix the polyaspartic acid ester resin, hydroxyacrylic resin, dispersant, pigments and fillers, wear-resistant additives, and anti-rust pigments weighed in step S01, and then grind until the fineness of the mixture is ≤30 μm;

[0035] S03. Prepare component A: add defoamer, leveling agent, solvent to the mixture prepared in step S02 and mix to obtain the formulated component A;

[0036] S04. Packaging: respectively package the component A prepared in step S03 and the component B weighed in step S01 to obtain the floor coating.

[0037] Specifically, in the above step ...

Embodiment 1

[0046] A kind of floor paint and preparation method thereof:

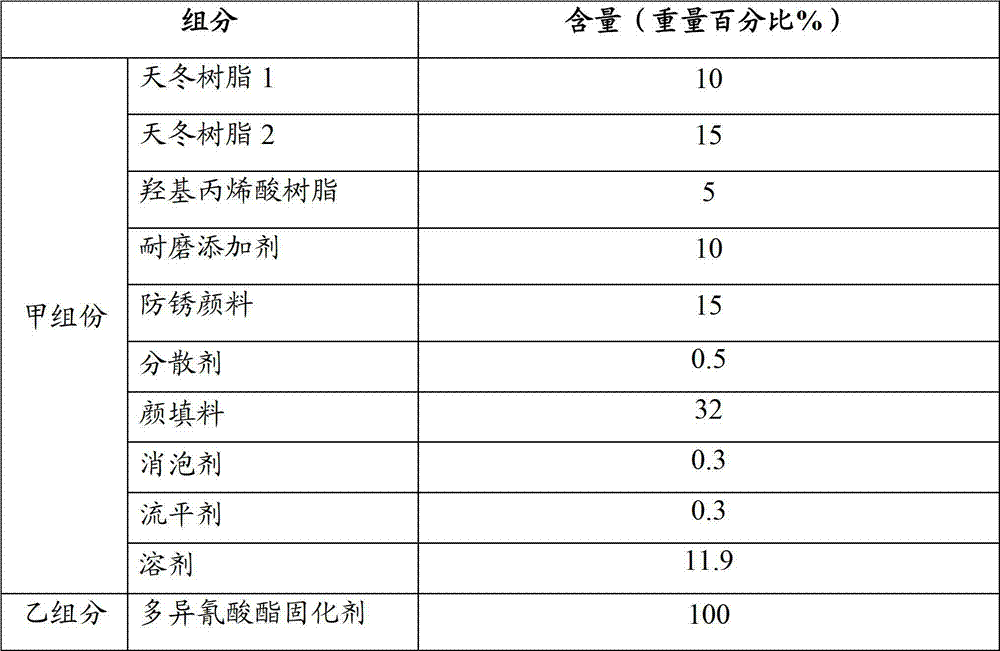

[0047] The floor paint consists of two components, A and B, and the composition and content of components A and B are as described in Table 11 below. Among them, the wear-resistant additive is nano-alumina of γ crystal form, the anti-rust pigment is zinc phosphate, modified zinc phosphate, aluminum tripolyphosphate, the dispersant is BYK-104S, the pigment is titanium dioxide, the filler is calcium carbonate, and the defoaming The agent is 5500 produced by Deqian, the leveling agent is DC-3 produced by Dow Corning, and the solvent is n-butyl acetate.

[0048] Table 11

[0049]

[0050]

[0051] The preparation method of the floor coating: the preparation of component A: first weigh the raw materials according to the formula ratio, and then add polyaspartic acid ester resin, dispersant, pigments, fillers, wear-resistant additives, and anti-rust pigments in sequence at the low-speed stage, and then continue to ...

Embodiment 2

[0056] A kind of floor paint and preparation method thereof:

[0057] The floor paint is composed of two components, A and B, and the composition and content of components A and B are as described in Table 21 below. Among them, the wear-resistant additive is γ crystal nano-alumina, the anti-rust pigment is modified zinc phosphate, the dispersant is BYK-104S, the pigment is phthalocyanine green, the filler is talcum powder, and the defoamer is 6500 produced by Deqian. The leveling agent is DC-3 produced by Dow Corning, and the solvent is n-butyl acetate.

[0058] Table 21

[0059]

[0060]

[0061] The preparation method of the floor paint: refer to the preparation method of the floor paint in Example 1.

[0062] The performance test of the floor coating prepared in Example 2: after mixing components A and B evenly, a mold making test is carried out, and the test methods of various properties can be performed according to conventional methods in the art. The relevant p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com