Water-based cleaning agent for soldering flux and preparation method thereof

A water-based cleaning agent and flux technology, applied in the field of cleaning agents, can solve the problems of easily causing skin cancer, environmental pollution, and high cost, and achieve the best cleaning effect, convenient use and less use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

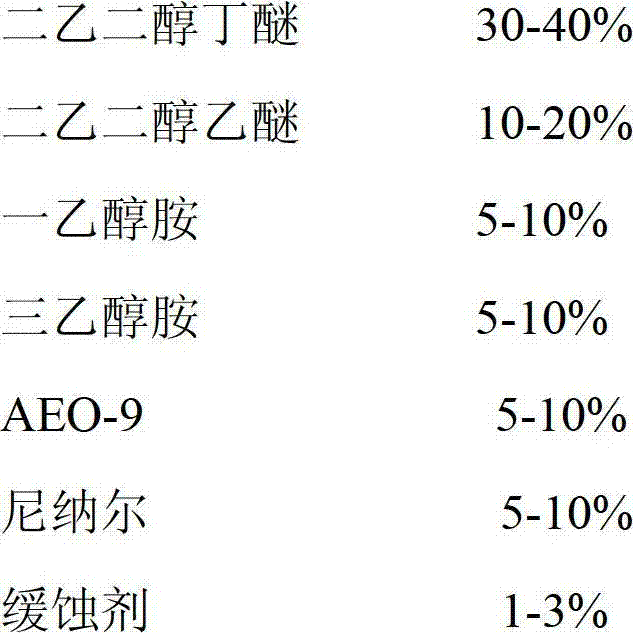

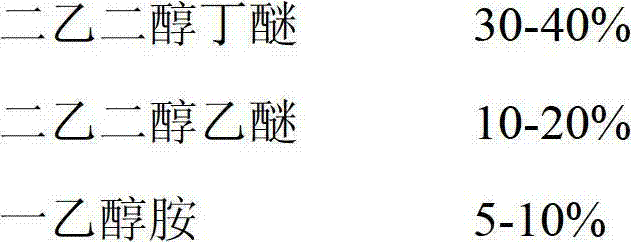

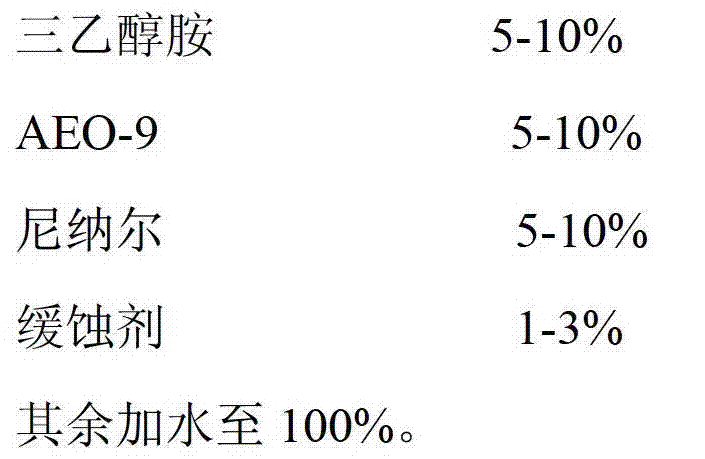

[0022] A flux water-based cleaning agent, its composition and weight are respectively (take 1000g flux water-based cleaning agent as an example):

[0023]

[0024]

[0025] A preparation method of flux water-based cleaning agent, the steps are as follows:

[0026] Add water to the reaction kettle, add the reaction amount of diethylene glycol butyl ether, diethylene glycol ethyl ether, monoethanolamine, triethanolamine, AEO-9, Ninar, corrosion inhibitor in turn under stirring, and mix and stir for 20-30 minutes That is, it becomes a flux water-based cleaning agent.

Embodiment 2

[0028] A kind of flux water-based cleaning agent, its composition and weight are respectively (taking 1000g flux water-based cleaning agent as an example)

[0029]

[0030] The steps of its preparation method are the same as in Example 1.

[0031] Mechanism of action of the present invention:

[0032] The first is to dissolve and clean away the flux and welding slag on the workpiece, and add a corrosion inhibitor to the water-based cleaning agent for the production of flux to protect the metal workpiece, and achieve the best cleaning effect through the above mechanism.

[0033] Application examples of this cleaning agent:

[0034] Add the mixed solution of the flux water-based cleaning agent of Example 1 or Example 2 and water to the liquid tank at a concentration of 20%, at a temperature of 60°C, soak the cleaned metal parts in the mixed solution for 30 minutes, and then ultrasonically clean After 30 minutes, rinse the workpiece with clean water.

[0035] Conclusion: Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com