Silane self-crosslinked polyolefin flexible insulation cable material and preparation method thereof

A soft insulation and self-crosslinking technology, applied in the field of polyolefin insulation materials, can solve the problems of inability to use electromechanical equipment and lack of soft characteristics, and achieve the effects of low cost, excellent processing performance, and guaranteed grafting degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

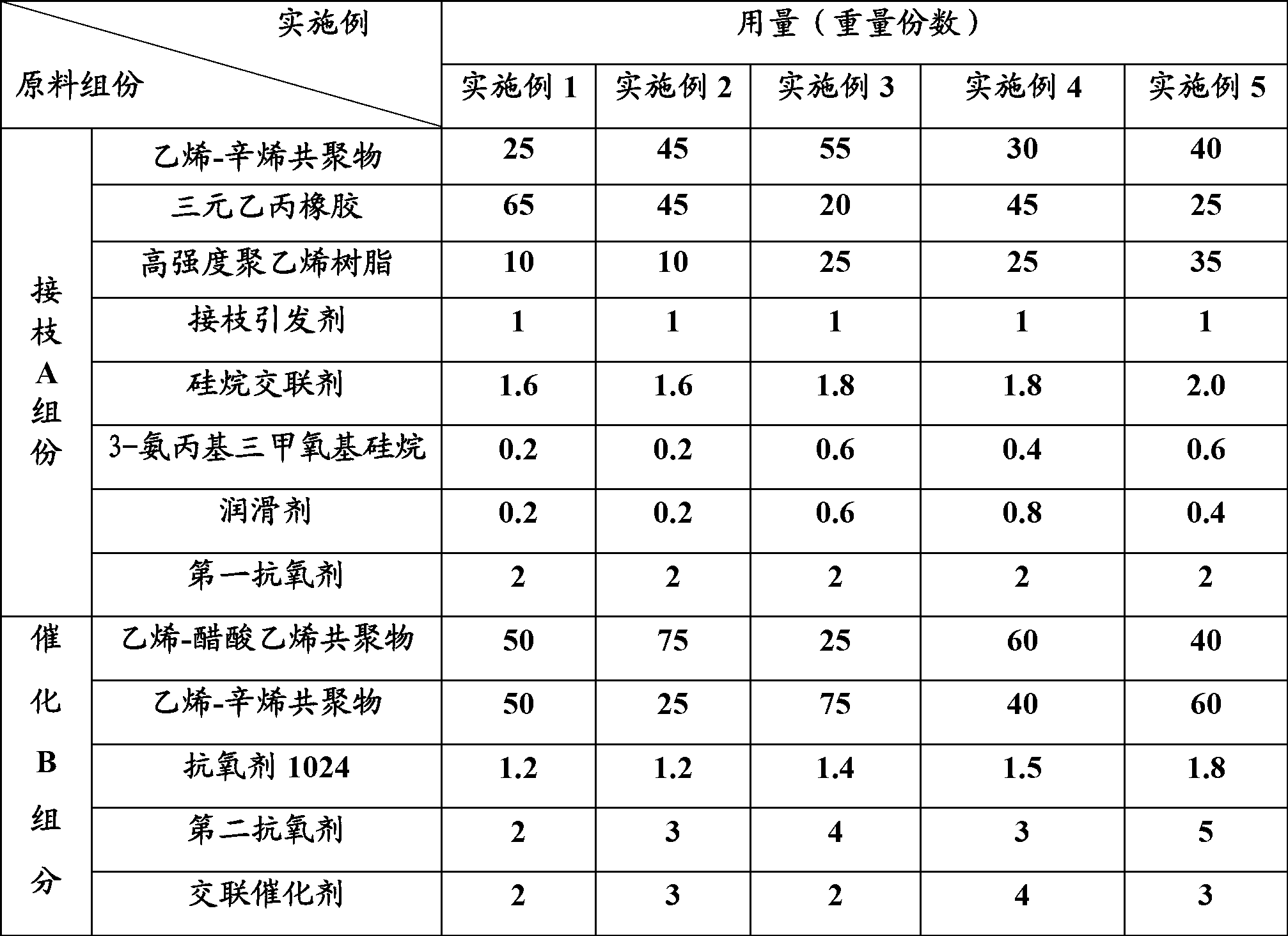

[0033] This example provides a method for preparing silane self-crosslinking polyolefin flexible insulating cable material at 125°C. The raw materials and dosages used are shown in Table 1, wherein:

[0034] The high tensile strength polyethylene resin is bimodal polyethylene produced by Borealis, brand: FB2230, and the melt index is 0.2g / 10min; the Mooney viscosity of EPDM rubber is 25, and the propylene content is 25wt%; ethylene copolymer, the Shore A hardness is 75; the first antioxidant is antioxidant 300, the lubricant is PPA, and the grafting initiator is DCP.

[0035] The vinyl acetate content of the ethylene-vinyl acetate copolymer is 28wt%; the silane crosslinking agent is vinyltrimethoxysilane; the third antioxidant comprises antioxidant 1010 and antioxidant 168 with a weight ratio of 1:1;

[0036] The crosslinking catalyst was dibutyltin dilaurate.

[0037] The preparation method of 125 DEG C silane self-crosslinking polyolefin flexible insulating cable material c...

Embodiment 2

[0042] This example provides a preparation method of silane self-crosslinking polyolefin flexible insulating cable material at 125°C. The raw materials and dosage used are shown in Table 1. The raw materials other than high-strength polyethylene resin and grafting initiator are the same as those in the example. 1 is the same.

[0043] In this example, the selected high-strength polyethylene resin is Exxon's metallocene polyethylene grade: 3518CB, and its melt index is 3.5g / 10min.

[0044] In this example, the grafting initiator is 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane (DBPH).

[0045] The preparation process of the silane self-crosslinking polyolefin flexible insulating cable material at 125°C is the same as that in Example 1.

Embodiment 3

[0047]This example provides a method for preparing a 125°C silane self-crosslinking polyolefin flexible insulating cable material. The raw materials and dosage used are shown in Table 1. The raw materials other than the silane crosslinking agent, lubricant and the third antioxidant are all Same as Example 1.

[0048] In this example, the silane crosslinking agent is vinyltriethoxysilane; the lubricant is silicone masterbatch; the third antioxidant includes antioxidant 1010 and antioxidant 168 in a weight ratio of 2:1.

[0049] The preparation process of the silane self-crosslinking polyolefin flexible insulating cable material at 125°C is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com