Anti-bacterial type ink jet aqueous carbon black ink

A black ink, ink-based technology, applied in ink, household utensils, applications, etc., can solve the problems of reducing water treatment fastness, sensitivity, and increasing the tendency of pigment migration, etc., to achieve excellent hue, high light fastness, good long-term The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Preparation of Acid Black 2:

[0036] 1) The reaction product of nitrobenzene and aniline

[0037] React 1.2mol nitrobenzene, 1.7mol aniline and 0.2mol ferrous chloride at about 185°C for 15 hours. Nigrosine was dissolved in excess aniline, then poured into dilute aqueous sodium hydroxide solution and stirred. The aqueous phase contains large amounts of iron salts; nigrosine is distilled from the organic phase and dried. The recovered solid phase is hereinafter referred to as solvent black 7 for short.

[0038] 2) Sulfonation reaction

[0039]Add 1600ml 98% sulfuric acid to a 5000ml stirred vessel. 1kg of solvent black 7 was slowly added little by little while stirring was turned on. The temperature was maintained at 90°C until complete dissolution. Add 19 liters of deionized water to the dilution vessel, and add the reaction mixture when the temperature is 70-80°C. The product (crude nigrosine) was isolated by filtration. 2.6kg of water and 180ml of 50% sodium ...

Embodiment 1

[0048] Get 260g of acid black 2 solution prepared by the above method, 1.2g deionized water, 30g ethanolamine, 30g photocatalyst powder and pour it into 1200g deionized water, and have a stirrer to fully mix and stir. During the stirring process, 500g Degus Sai S4 carbon black is slowly poured into the mixer, and after the mixing is completed, a semi-finished carbon black ink is obtained.

[0049] Pour the semi-finished carbon black ink into a grinder and grind for 1.5 hours, then filter the semi-finished carbon black ink through a 3-micron hydrophobic microporous filter membrane to obtain the required stock solution of carbon black ink.

[0050] When in use, dilute the stock solution of carbon black ink to an ink with a dye content of 6%, and then put it into an inkjet printer for printing.

Embodiment 2

[0052] Take 400g of Acid Black 2, 30g of aminoethanol, and 32g of photocatalyst powder prepared by the above-mentioned method and pour them into 2600g of deionized water, and mix and stir in a blender. During the stirring process, slowly add 750g of Degussa FW2 carbon black to make carbon Black ink semi-finished products.

[0053] Pour the semi-finished carbon black ink into the grinder and grind for 2 hours, then filter the semi-finished carbon black ink through a 3-micron melt-blown filter to obtain the required stock solution of carbon black ink.

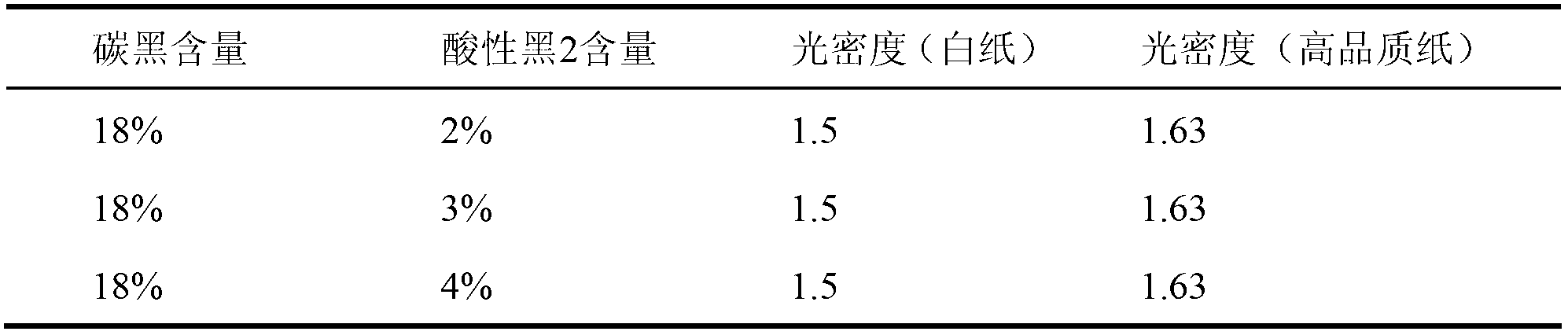

[0054] When in use, the carbon black ink stock solution is diluted to an ink with a dye content of 6%, which can be put into an inkjet printer for printing, and the printed matter obtained by printing has an optical density of 1.4-1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com