Depth purification method for isobutene

A technology for deep purification and isobutylene, applied in the field of olefin purification, can solve the problems of affecting the utilization of isobutylene, affecting the quality of products, deactivating the catalyst for synthesizing butyl rubber, etc., to reduce the yield, achieve significant economic benefits, and improve the conversion rate and selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

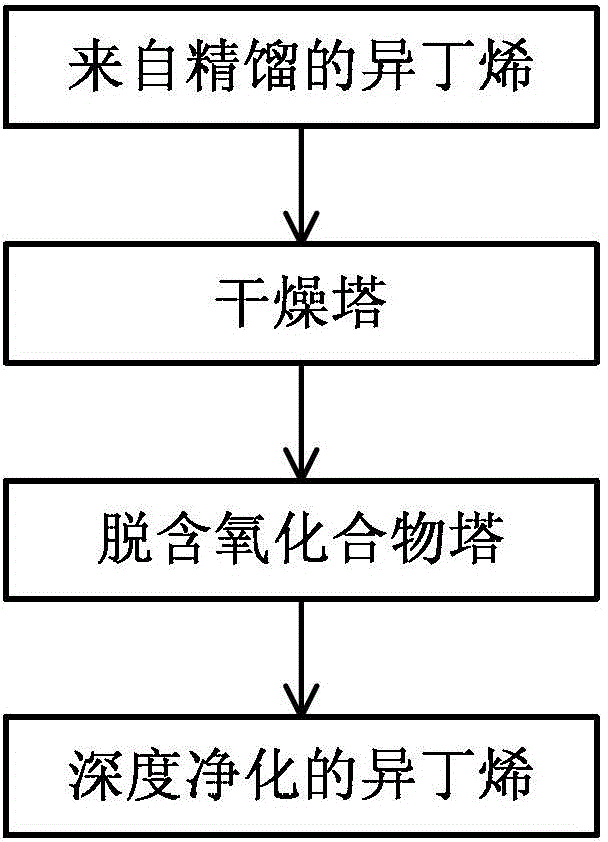

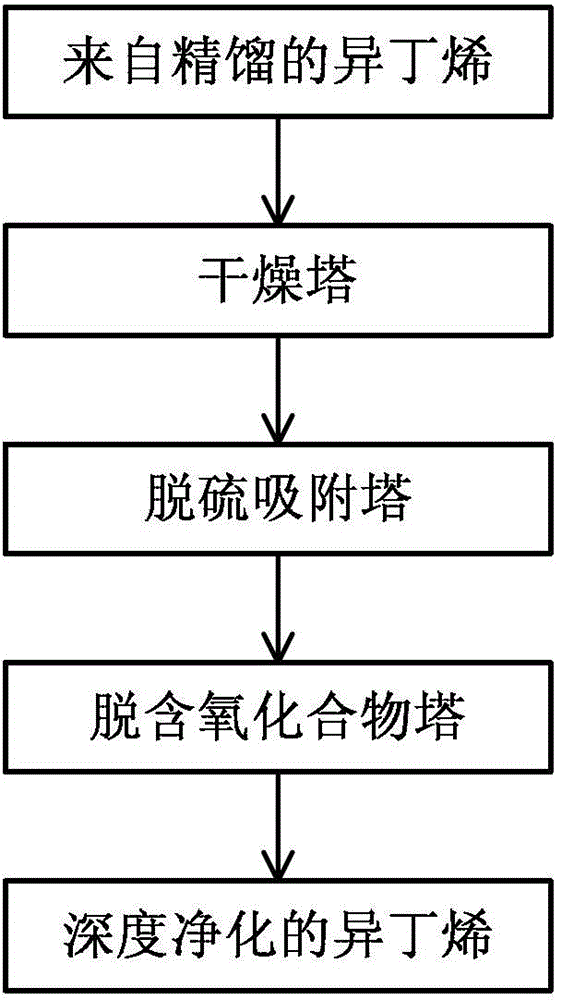

[0024] The present embodiment provides a kind of deep purification method of isobutylene, and its flow process is as follows figure 2 Shown, this depth purification method comprises the steps:

[0025] 1. Fill 500mL of 4A molecular sieve and 500mL of desulfurization adsorbent in the drying tower, desulfurization adsorption tower and oxygenate removal tower respectively (CuO content is 3-4wt%, NaY molecular sieve content is 36wt%, and the balance is Al 2 o 3 ) and 500 mL of oxygenate-removing adsorbent (Na 2 O content is 2-3wt%, NaY molecular sieve content is 43wt%, and the balance is Al 2 o 3 ), wherein, the drying tower, the desulfurization adsorption tower and the oxygenate removal tower are respectively stainless steel reactors with an internal diameter of 50mm and a length of 310mm;

[0026]2. Dehydration and drying treatment: the isobutene after rectification (the isobutene after cracking and rectification of the MTBE raw material, the impurity content is as shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com