Preparation method of adsorbent capable of effectively reducing content of crotonaldehyde in cigarette smoke

A technology for cigarette smoke and crotonaldehyde, which is applied to chemical instruments and methods, other chemical processes and other directions, can solve problems such as the inability to prepare molecularly imprinted polymers of crotonaldehyde, and achieve the effects of low cost, obvious effect and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

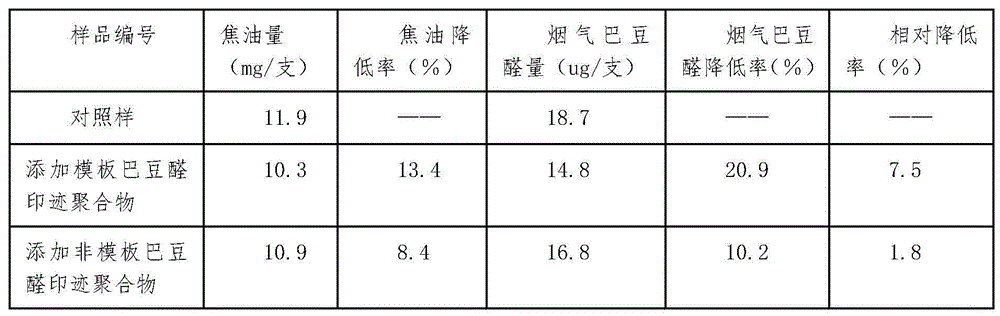

Examples

Embodiment 1

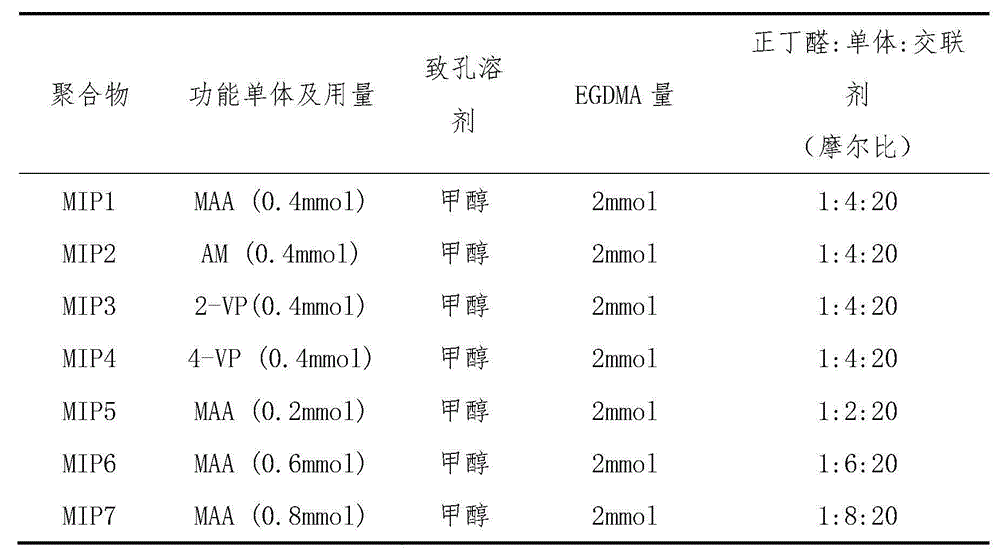

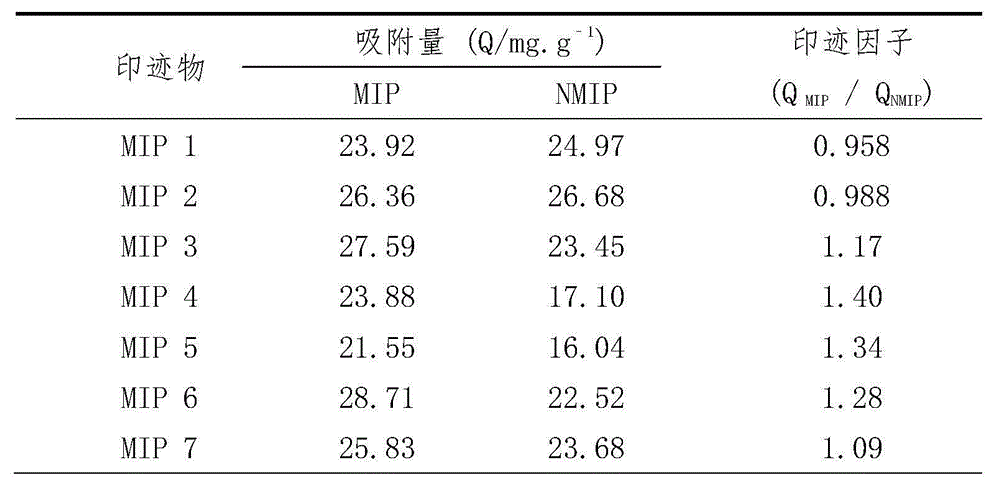

[0019] Choose n-butyraldehyde as the template molecule, the functional monomer is α-methacrylic acid (MAA), 2-vinylpyridine (2-VP), 4-vinylpyridine (4-VP) or acrylamide (AM) One, ethylene glycol dimethacrylate (EGDMA) as the crosslinking agent, azobisisobutyronitrile (AIBN) as the initiator.

[0020] Weigh 0.1mmol of n-butyraldehyde and dissolve it in 10mL of methanol, add the specified amount and specified type of functional monomer according to Table 1, and shake at a constant temperature at 25°C for 3 hours to fully react the imprinted molecules and functional monomers, then add the specified amount EDGMA and different amounts of AIBN, mix well, transfer to 50mL glass ampoule, pass N 2 Deoxidize for 5-10 minutes, then seal it under anaerobic conditions and place it in a constant temperature shaker at 60°C for 24 hours, then filter directly. The obtained polymer was Soxhlet extracted with 1:9 (v / v) glacial acetic acid-methanol solution until there were no imprinted molecul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com