Flame-retardant low-heat-release type gas extraction drilled hole plugging material and preparation method thereof

A plugging material and gas drainage technology, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problem that the stability of the sealing effect cannot be guaranteed, the process of spontaneous combustion and oxidation of coal body is accelerated, and the foaming ratio of grouting materials is high. problems, to achieve significant economic and social benefits, increase compactness, and ensure the effect of gas drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

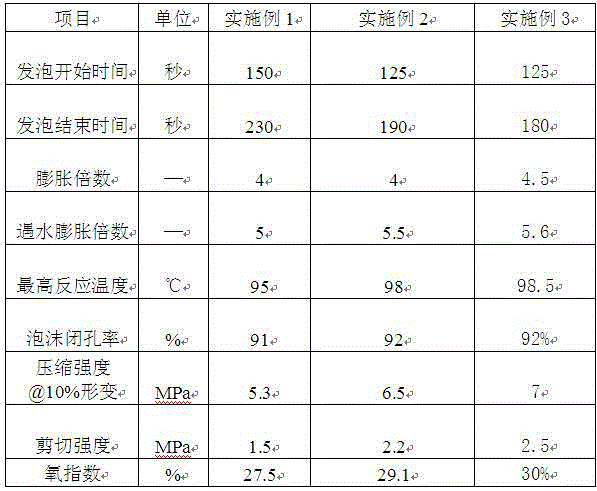

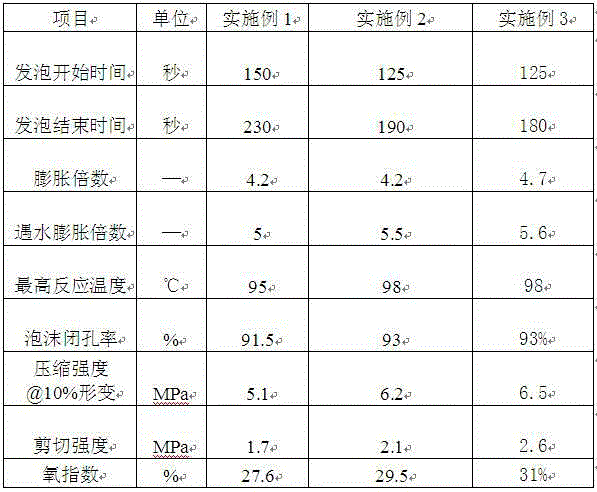

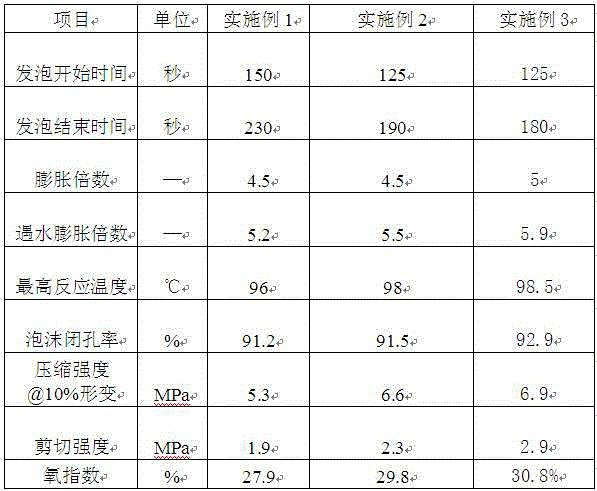

Embodiment 1

[0036] In a 200L stainless steel dry mixing container, weigh: polyether polyol 1: 45kg; polyether polyol 2: 5kg; Mannich polyol: 15 kg; polyester polyol: 1 kg; catalyst (2- Hydroxypropyltrimethylisooctanoate, 1,3,5-tris(dimethylaminopropyl)-hexahydrotriazine, potassium octanoate (65:15:20 by weight): 0.01 kg; foam stable Agent: 1.5 kg; Foaming agent (weight ratio of water to HFC-365mfc is 25 : 75): 1kg; Flame retardant (expandable graphite): 10 kg, Stabilizer (α-methylstyrene): 0.5 kg. And add them into the stirring container one by one, and stir at room temperature for 30-60 minutes.

Embodiment 2

[0038] In a 200L stainless steel dry stirring container, weigh: polyether polyol 1: 60kg; polyether polyol 2: 8kg; Mannich polyol: 22 kg; polyester polyol: 2.5 kg; catalyst (2- Hydroxypropyltrimethylisooctanoate, 1,3,5-tris(dimethylaminopropyl)-hexahydrotriazine, potassium octanoate (65:15:20 by weight): 2 kg; foam stabilized Agent: 2.2kg; Foaming agent (the weight ratio of water and HFC-365mfc is 25:75): 3kg; Flame retardant (expandable graphite): 20 kg, stabilizer (α-methylstyrene): 1kg .And add them into the stirring container in turn, and stir at room temperature for 30-60 minutes.

Embodiment 3

[0040]In a 200L stainless steel dry stirring container, weigh: polyether polyol 1: 75kg; polyether polyol 2: 15kg; Mannich polyol: 30 kg; polyester polyol: 5kg; catalyst (2-hydroxy Propyltrimethylisooctanoate, 1,3,5-tris(dimethylaminopropyl)-hexahydrotriazine, potassium octanoate (65:15:20 by weight): 3 kg; foam stabilizer : 3kg; foaming agent (weight ratio of water and HFC-365mfc is 25:75): 6kg; flame retardant (expandable graphite): 30 kg, stabilizer (α-methylstyrene): 1.5kg. And add them into the stirring container in turn, and stir at room temperature for 30-60 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com