Continuous carbon fiber reinforced nylon composite material used under continuous high temperature environment, and preparation method thereof

A nylon composite material, high-temperature environment technology, applied in the field of nylon composite materials, can solve the problems of failing to give full play to carbon fiber and the decline of comprehensive mechanical properties of materials, and achieve a small friction coefficient, ultra-high comprehensive mechanical properties, and good dimensional stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Mix 100 parts of nylon 6 resin, 1 part of compatibilizer PP-g-MAH, 0.3 part of antioxidant 1098, 0.5 part of organic copper salt compound copper dithiocarbamate, 0.2 part of carbon free radical scavenger 136 , 0.3 part of anti-hydrolysis agent triallyl isocyanurate, 0.1 part of lubricant zinc stearate are mixed evenly in a high mixer;

[0022] (2) The uniformly mixed material obtained in step 1) is melted and extruded through the extruder, and then the continuous carbon fiber is fully impregnated through the impregnation head, and the nylon composite material is controlled by controlling the extrusion amount of the extruder and the addition of continuous carbon fiber. The content of medium carbon fiber is 5 parts;

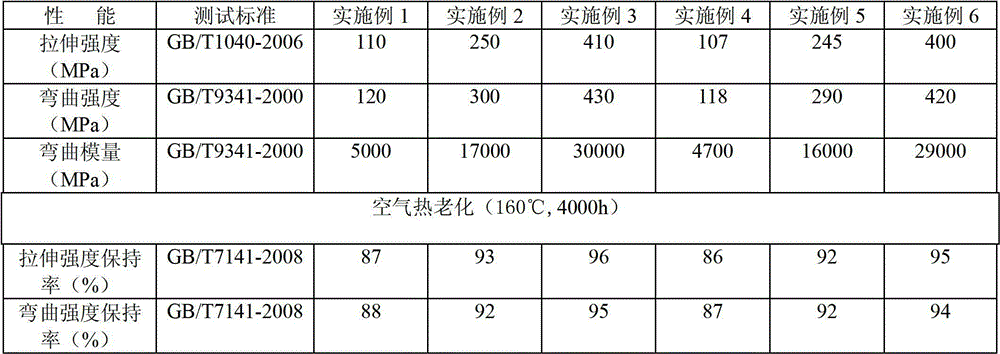

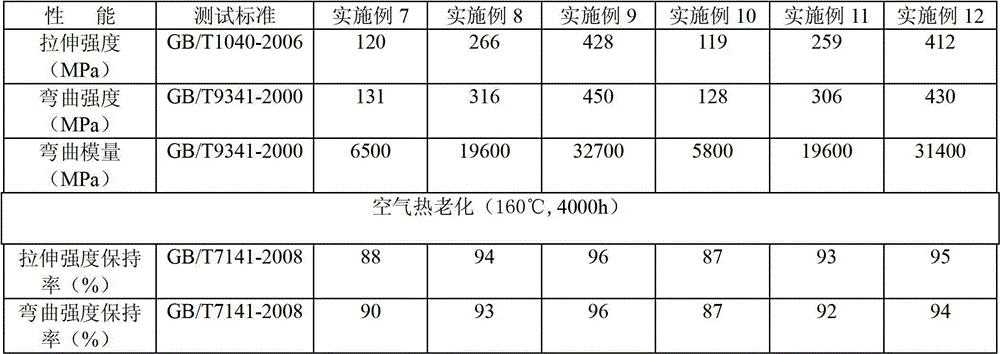

[0023] (3) The continuous carbon fiber impregnated material obtained in step 2) was drawn, cooled, cut to length and dried to obtain a continuous carbon fiber reinforced nylon 6 composite material. The performance test results of the obtained material ar...

Embodiment 2

[0025] (1) Mix 100 parts of nylon 6 resin, 5 parts of compatibilizer PP-g-MAH, 0.3 parts of antioxidant 1098, 0.5 parts of organic copper salt compound copper dithiocarbamate, 0.2 parts of carbon free radical scavenger 136 , 0.3 parts of anti-hydrolysis agent triallyl isocyanurate, 0.1 part of lubricant zinc stearate are mixed evenly in a high mixer; (lack of anti-hydrolysis agent)

[0026] (2) The uniformly mixed material obtained in step 1) is melted and extruded through the extruder, and then the continuous carbon fiber is fully impregnated through the impregnation head, and the nylon composite material is controlled by controlling the extrusion amount of the extruder and the addition of continuous carbon fiber. The content of medium carbon fiber is 50 parts;

[0027] (3) The continuous carbon fiber impregnated material obtained in step 2) was drawn, cooled, cut to length and dried to obtain a continuous carbon fiber reinforced nylon 6 composite material. The performance te...

Embodiment 3

[0029] (1) Mix 100 parts of nylon 6 resin, 15 parts of compatibilizer PP-g-MAH, 0.3 parts of antioxidant 1098, 0.5 parts of organic copper salt compound copper dithiocarbamate, 0.2 parts of carbon free radical scavenger 136 , 0.3 parts of anti-hydrolysis agent triallyl isocyanurate, and 0.1 part of lubricant zinc stearate are mixed uniformly in a high-speed mixer; (2) The uniformly mixed material obtained in step 1) is melted through an extruder After extrusion, the continuous carbon fiber is fully impregnated through the impregnation head, and the content of carbon fiber in the nylon composite material is controlled to 150 parts by controlling the extrusion volume of the extruder and the addition of continuous carbon fiber;

[0030] (3) The continuous carbon fiber impregnated material obtained in step 2) was drawn, cooled, cut to length and dried to obtain a continuous carbon fiber reinforced nylon 6 composite material. The performance test results of the obtained material are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com