Optical fiber connecting method

A connection method and optical fiber technology, applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problems of lowering the laser threshold, abnormally sensitive optical signal isolation, laser oscillation, etc., and achieve the effect of ensuring the quality of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

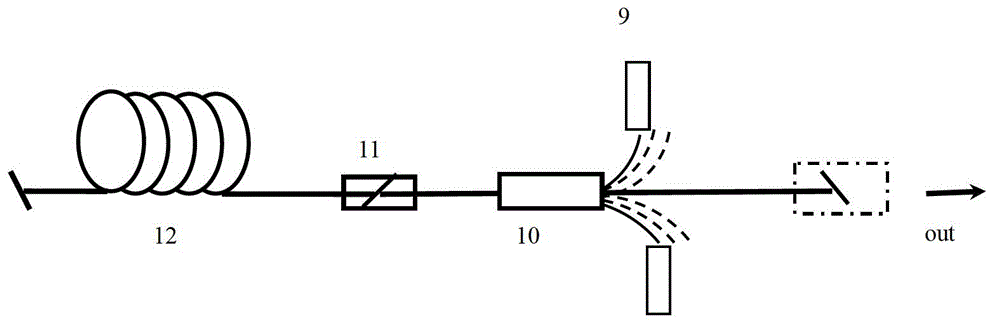

[0036] like figure 2 As shown, this example is an embodiment in which the method of the present invention is used in an optical fiber superfluorescent seed source. The broadband superfluorescent seed source is composed of a semiconductor laser 9 , a (n+1)x1 pump beam combiner 10 , an angle fusion point 11 , and a Yb-doped double-clad fiber 12 . The semiconductor laser 9 is used as a pumping source, and its tail fiber is connected to the input fiber of the (n+1)x1 pumping beam combiner 10, and the output end of the (n+1)x1 pumping beam combiner 10 is welded at an angle Connect with one end of the Yb-doped double-clad fiber 12, 11 is the angle fusion welding point, the other end of the Yb-doped double-clad fiber 12 and the signal end of the (n+1)x1 pumping beam combiner 10 are all cut into The 8-degree angle serves as the output end of the fiber optic superfluorescence. Because the connection between the (n+1)x1 pumping beam combiner 10 and the Yb-doped double-clad fiber 12 i...

Embodiment 2

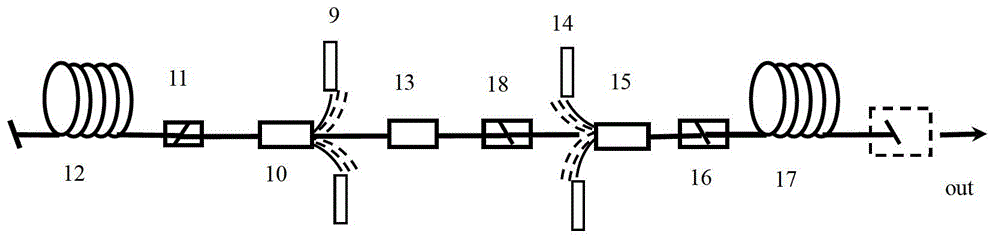

[0038] like image 3 As shown, this example is an embodiment in which the method of the present invention is used in an optical fiber superfluorescent seed source and its amplifier. The main oscillation power amplification MOPA structure adopted mainly includes two parts: a broadband superfluorescent seed source and an optical fiber power amplifier. The broadband superfluorescent seed source consists of a first semiconductor laser 9, a first (n+1)x1 pump beam combiner 10, a first angle fusion point 11, a first Yb-doped double-clad fiber 12 and a pump light leaker 13 constitute. Wherein the first semiconductor laser 9 is used as a pumping source, and its tail fiber is connected to the input fiber of the first (n+1)x1 pumping beam combiner 10, and the output of the first (n+1)x1 pumping beam combiner 10 The end is connected with an end of the first Yb-doped double-clad optical fiber 12 by angle fusion welding, 11 is the first angle fusion welding point, and the other end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com