Novel microalgal food compositions

A composition and food technology, applied in food science, food ingredients, food preservation, etc., can solve problems such as instability and oxidation of DHA

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

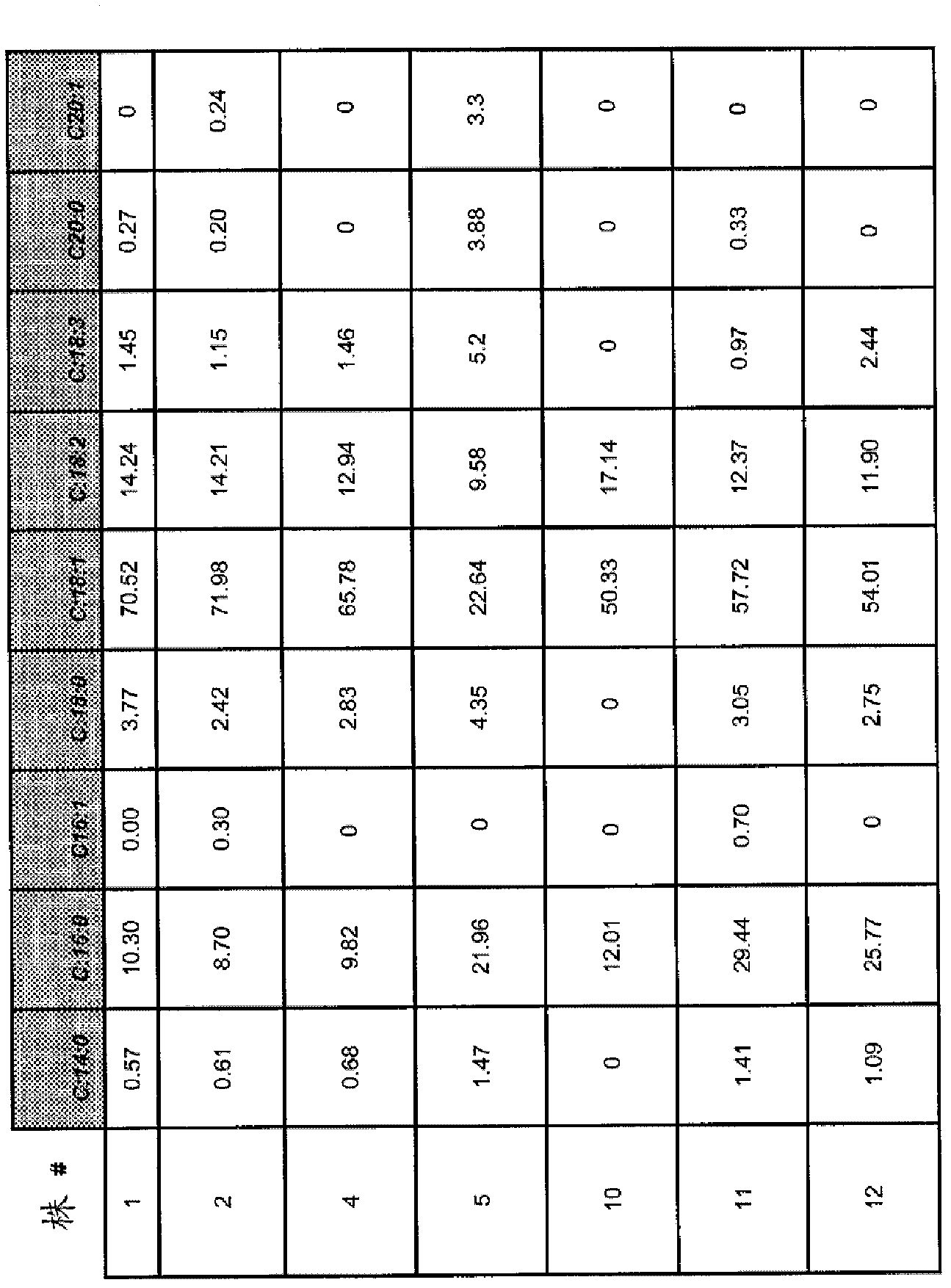

[0359] Cultivate microalgae for high oil content

[0360] The microalgal strains were grown in shake flasks with the goal of obtaining more than 20% oil by dry cell weight. The medium in the shake flask used was as follows: K 2 HPO 4 : 4.2g / L, NaH 2 PO 4 : 3.1g / L, MgSO 4 ·7H 2 O: 0.24g / L, citric acid monohydrate: 0.25g / L, CaCl 2 2H 2 O: 0.025g / L, yeast extract: 2g / L and 2% glucose. The frozen cells were thawed at room temperature, 500ul of cells were added to 4.5ml of medium, and grown on a 6-well plate at 28°C for 7 days while stirring (200rpm). Dry cell weight was determined by centrifuging 1 ml of the culture at 14,000 rpm for 5 minutes in pre-weighed Eppendorf tubes. The culture supernatant was discarded, and the resulting cell pellet was washed with 1 ml of deionized water. The culture was centrifuged again, the supernatant was discarded, and the cell pellet was placed at -80°C until frozen. Samples were then freeze-dried for 24 hours and the dry cell weight ...

example 2

[0367] To generate algal biomass with high oil content, three fermentations were performed with three different media formulations. The first formulation (medium 1) is based on the medium described by Wu et al. (1994 Science in China, volume 37, phase 3, pages 326-335), and the composition per liter is: KH 2 PO 4 , 0.7g; K 2 HPO 4 , 0.3g; MgSO 4 -7H 2 O, 0.3g; FeSO 4 -7H 2 O, 3mg; Thiamine hydrochloride, 10μg; Glucose, 20g; Glycine, 0.1g; H 3 BO 3 , 2.9 mg; MnCl 2 -4H 2 O, 1.8 mg; ZnSO 4 -7H 2 O, 220 μg; CuSO 4 -5H 2 O, 80 μg; and NaMoO 4 -2H 2 O, 22.9 mg. The second substratum (medium 2) is derived from the substratum in the shake flask among the example 1, and the composition of every liter is: K 2 HPO 4 , 4.2g; NaH 2 PO 4 , 3.1g; MgSO 4 -7H 2 O, 0.24g; Citric Acid Monohydrate, 0.25g; Calcium Chloride Dehydrate, 25mg; Glucose, 20g; Yeast Extract, 2g. The third culture medium (medium 3) is a mixed culture medium, and the composition per liter is: K 2 H...

example 3

[0373] Preparation of biomass for food products

[0374] Microalgal biomass was produced by culturing microalgae as described in any of Examples 1-2. Harvest microalgal biomass from fermenters, flasks, or other bioreactors.

[0375] Comply with GMP procedures. Food, food If there is a clear possibility of contamination of contact surfaces or food packaging materials, he shall be prohibited from performing any operation expected to result in such contamination until the condition is corrected. Instruct personnel to report such medical conditions to their supervisor. All workers who come into direct contact with microalgal biomass, biomass contact surfaces, and biomass packaging materials are expected to observe hygienic practices while on duty to the extent necessary to protect the microalgal biomass from contamination. Methods of maintaining cleanliness include, but are not limited to: (1) Wearing garments suitable for handling in a manner that protects biomass, biomass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com