Water resistance type film coating composition and application thereof

A film-coating and water-resistant technology, applied in drug delivery, pharmaceutical formulations, etc., can solve problems such as poor compatibility between main materials and plasticizers, and achieve improved release behavior, good pH change sensitivity, and water resistance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

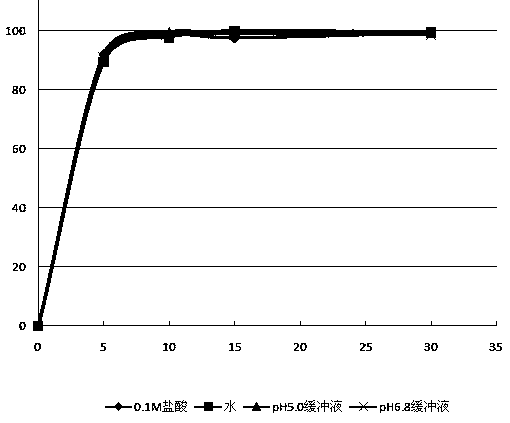

[0036] Example 1: Adjustment of product release behavior after coating

[0037] Pinaverium bromide is an antispasmodic agent acting on the gastrointestinal tract. It is a calcium antagonist that acts by inhibiting the influx of calcium ions into intestinal smooth muscle cells. For the consideration of clinical safety, the drug is subjected to isolation coating by using the water-resistant film coating composition of the present invention, so as to prevent the release of pinaverium bromide in the esophagus from causing discomfort to patients.

[0038] Take 10 grams of polyacrylic acid resin IV and 2.5 grams of stearic acid and add them to 87.5 grams of absolute ethanol. After stirring and dissolving in a water bath at 50°C to 55°C, use a conventional film coating process to coat 200 grams of pinaverium bromide tablets. The core (specification 50mg / tablet) is coated, and samples are taken when the weight of the tablet core increases by 1%, 2% and 3%.

[0039] Water-resistant ti...

Embodiment 2

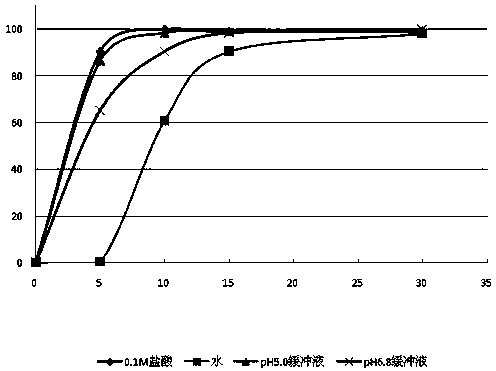

[0049] Example 2 The impact of coating materials with different proportions on the water separation time of tablets

[0050] Take 8 grams of polyacrylic acid resin IV and 2 grams of stearic acid, add them to 90 grams of absolute ethanol, stir and dissolve in a water bath at 50°C~55°C, and then use a conventional film coating process to coat 150 grams of blank tablet cores. Coating, coating until the weight gain of the tablet core was 1%, 2% and 3%.

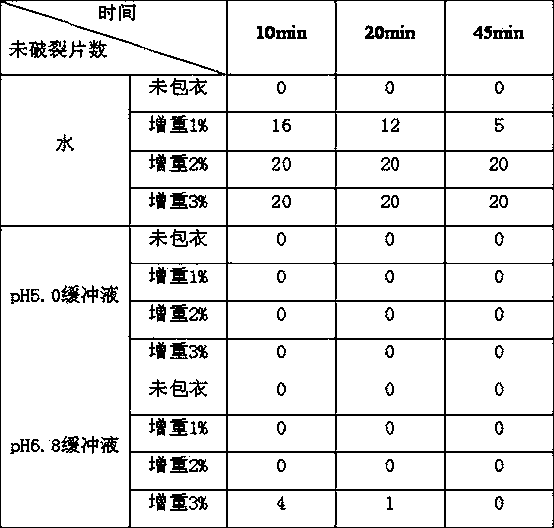

[0051] The control data before and after coating are shown in Table 3.

[0052] Table 3. Effect of coating on product release behavior (water resistance time in standing state)

[0053]

[0054] *Gain refers to the actual weight gain of the coating. The data in the table is the number of remaining unbroken tablets (pieces) in the cup.

[0055] Conclusion: The release of the product in water can be delayed after coating with different proportions of the composition.

Embodiment 3

[0056] Example 3 The impact of coating materials with different proportions on the water separation time of tablets

[0057] Take 12 grams of polyacrylic acid resin IV and 3 grams of stearic acid, add them to 85 grams of absolute ethanol, stir and dissolve in a water bath at 50°C~55°C, and then use a conventional film coating process to coat 150 grams of blank tablet cores. Coating, coating until the weight gain of the tablet core was 1%, 2% and 3%.

[0058] The control data before and after coating are shown in Table 4.

[0059] Table 4. Effect of coating on product release behavior (water resistance time in standing state)

[0060]

[0061] *Gain refers to the actual weight gain of the coating. The data in the table is the number of remaining unbroken tablets (pieces) in the cup.

[0062] Conclusion: The release of the product in water can be delayed after coating with different proportions of the composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com