Cadmium telluride nanowire and preparation method thereof

A technology of cadmium telluride and nanowires, which is applied in the field of nanowires, can solve the problems of rough surface of cadmium telluride nanowires, affecting the control of photoelectric conversion, complicated liquid phase method, etc., and achieves good application development prospects and easy experimental process. Good control and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

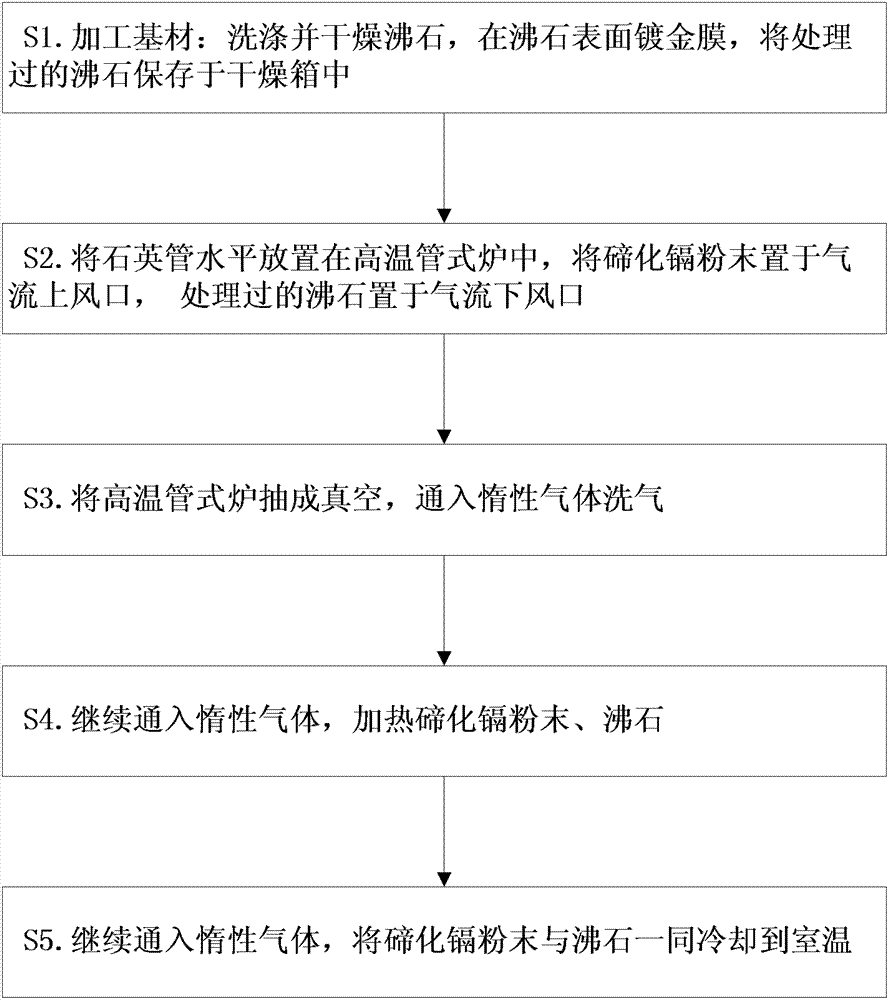

[0029] A preparation process of cadmium telluride nanowires is:

[0030] S1. Processing substrate: Wash 4A zeolite 12 in ultrasonic waves with acetone, alcohol, and deionized water for ten minutes, place in a vacuum drying oven to dry thoroughly after washing, and coat a layer of gold film on the surface of 4A zeolite 12. The processed 4A zeolite 12 is stored in a dry box;

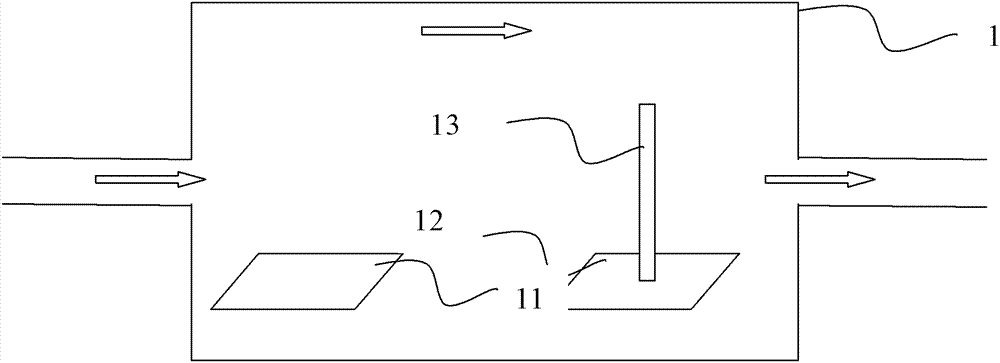

[0031] S2. Place the quartz tube 1 horizontally in a high-temperature tube furnace, take 10g of pure cadmium telluride powder 11 and place it at the upper tuyere of the airflow, and place the treated 4A zeolite 12 at the lower tuyere of the airflow;

[0032] S3. Evacuate the high-temperature tube furnace, inject argon gas for three times, and control the air pressure in the high-temperature tube furnace to 1×10 -4 torr;

[0033] S4. Continue to feed argon, the flow rate of argon is controlled at 20sccm, the pressure in the high temperature tube furnace is adjusted to 0.15atm, the temperature of the heati...

Embodiment 2

[0039] Sometimes, in order to make the choice of cadmium telluride nanowire substrates wider and the preparation process easier to operate, natural mordenite can be used as the substrate and bismuth film as the catalyst. The specific process is as follows:

[0040] S1. Process the base material: wash the natural mordenite 12 with acetone, alcohol, and deionized water in ultrasonic waves for ten minutes, place it in a vacuum drying oven to dry thoroughly after washing, and coat a layer of bismuth film on the surface of the natural mordenite 12 , the processed natural mordenite 12 is stored in a dry box;

[0041] S2. Place the quartz tube 1 horizontally in a high-temperature tube furnace, take 10g of pure cadmium telluride powder 11 and place it at the upper tuyere of the airflow, and place the treated natural mordenite 12 at the lower tuyere of the airflow;

[0042] S3. Evacuate the high-temperature tube furnace, inject argon gas for three times, and control the air pressure in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com