Monolithic integrated CMOS (Complementary Metal Oxide Semiconductor) MEMS (Micro-electromechanical Systems) multilayer metal three-axis capacitive accelerometer and manufacturing method thereof

An acceleration sensor and multi-layer metal technology, applied in the direction of measurement of acceleration, velocity/acceleration/shock measurement, electric solid devices, etc., can solve the problem of large overall size of the three-axis capacitive acceleration sensor, complex process of the three-axis capacitive acceleration sensor, To solve problems such as low authenticity rate, achieve good release effect, flexible wiring scheme, and shorten the connection distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] specific implementation plan

[0035] Combine now Figure 1 to Figure 16 The present invention will be described in detail.

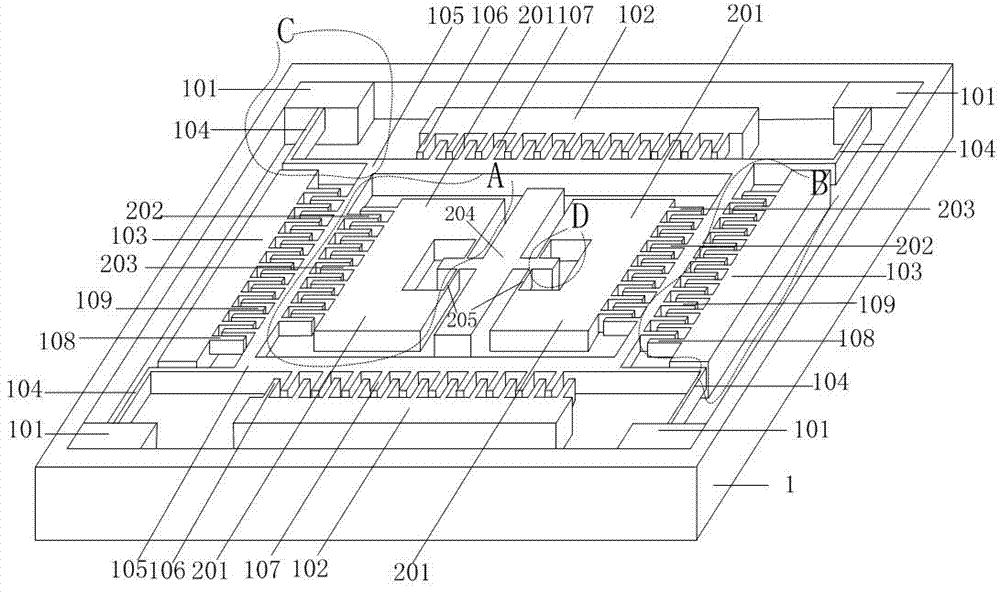

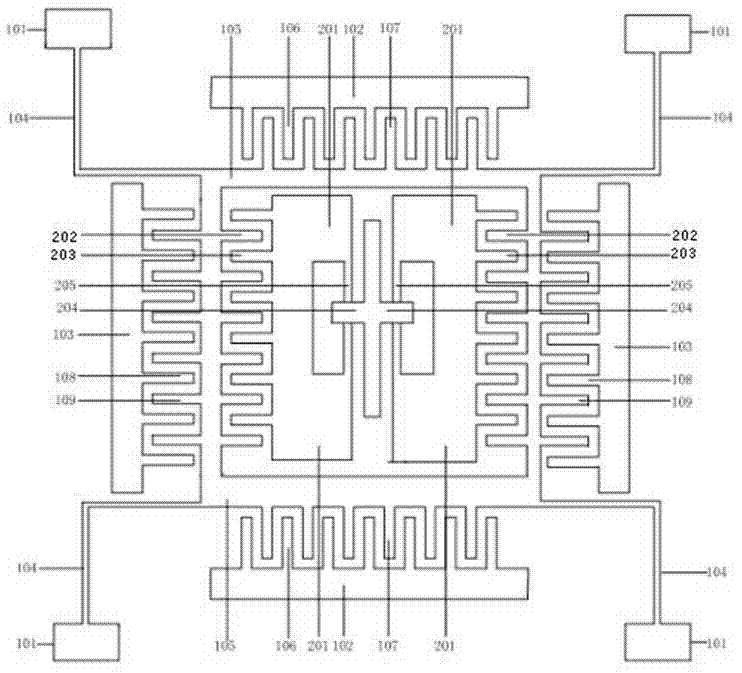

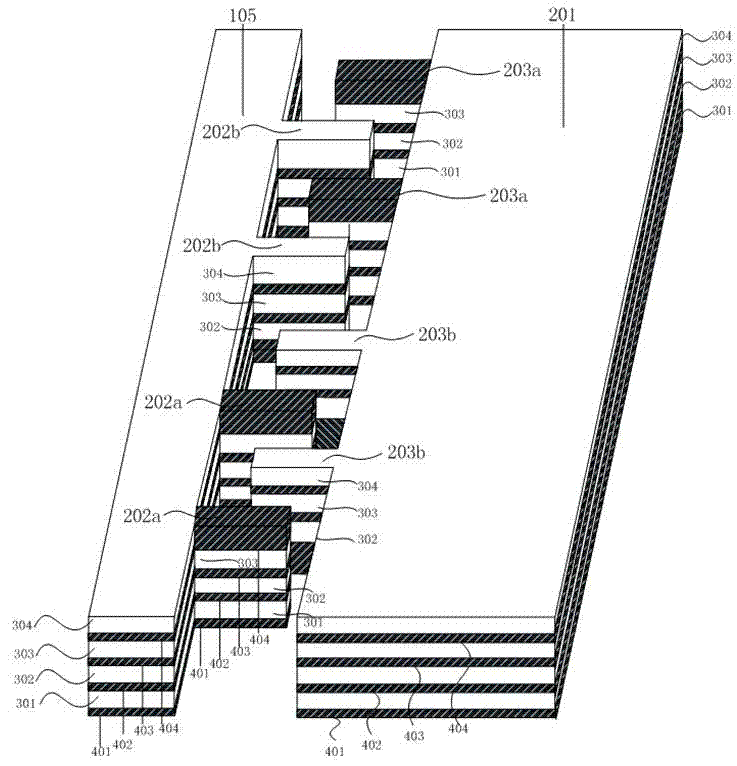

[0036] A monolithic integrated CMOS MEMS multilayer metal triaxial capacitive acceleration sensor, including a substrate 1, the triaxial acceleration sensor is composed of an anchor body, an acceleration detection mass, a fixed comb electrode, a movable comb electrode and a beam Wherein, the anchor body includes an angle anchor body 101, an x-axis anchor body 103, a y-axis anchor body 102, and a center anchor body 204; the acceleration proof mass includes a horizontal acceleration proof mass 105 and a z-axis proof mass 201; The fixed comb electrodes include the y-axis fixed comb electrode 106, the x-axis fixed comb electrode 108, and the z-axis fixed comb electrode 202; the movable comb electrodes include the y-axis movable comb electrode 107, the x-axis Toward the movable comb electrode 109 and the z-axis movable comb electrode 203; the beam i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com