Particle coating preparation

A granule and tablet technology, applied in the field of fast disintegrating tablets in the oral cavity, can solve the problems of residual irritation, insufficient masking, affecting drug efficacy, etc., and achieve the effects of good dissolution, excellent ingestion, and maintenance of dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

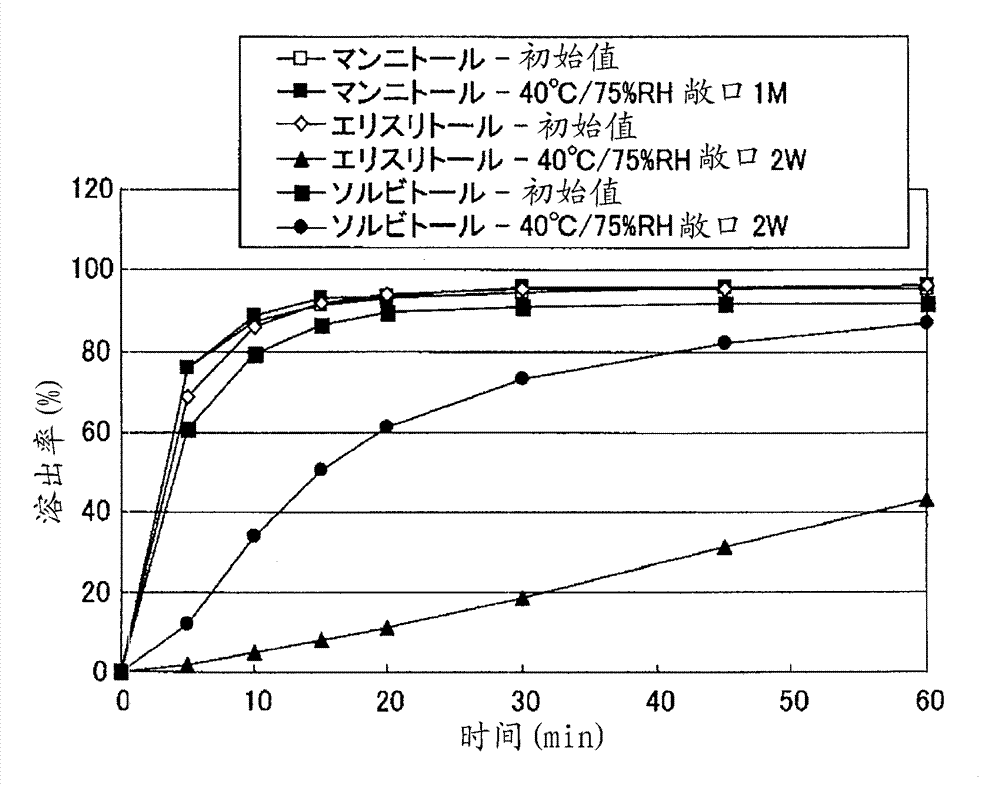

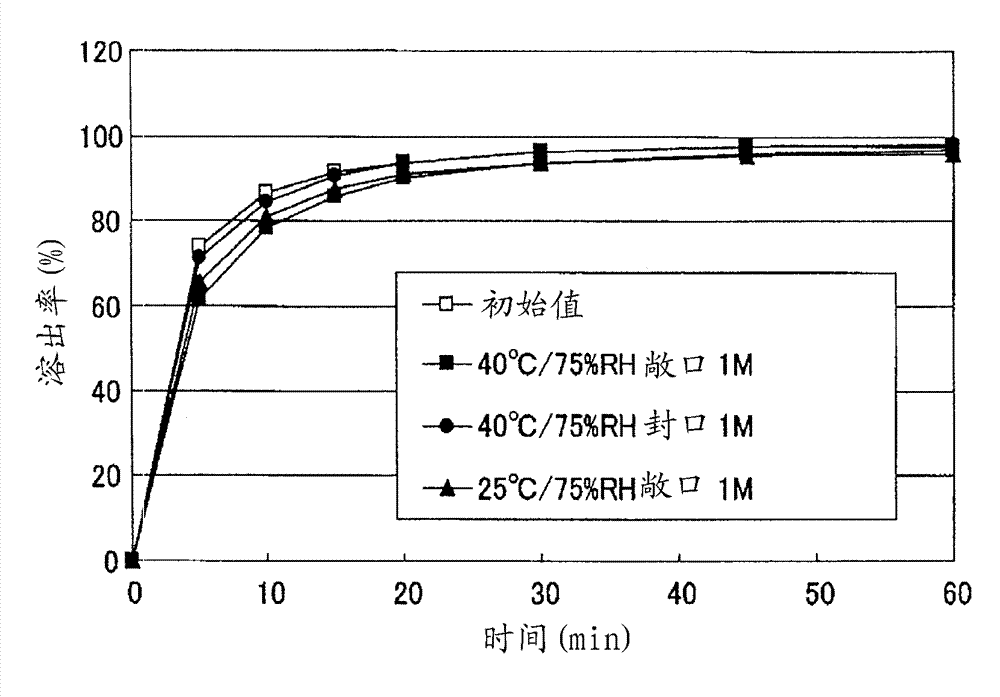

[0065] [Example 1] (Methacrylic acid copolymer coating masking + mannitol coating)

[0066] Add 12.6 g of polyethylene glycol 6000 (NOF, trade name; polyethylene glycol 6000P) to 650.2 g of pure water and dissolve it, then add methacrylic acid copolymer LD (Ebonick, trade name; オイドラギット L30D55) 420.0 g, fully stirred to prepare a coating dispersion. Next, 70 g of D-mannitol (Mitsubishi Corporation Fudotec) was added and dissolved in 630 g of pure water to prepare a coating liquid.

[0067] Put 300 g of Compound I and 15 g of light anhydrous silicic acid (Floint Industries) into a microparticle coating and granulation device (Paurek, MP-01SFP), spray 984.0 g of the above-mentioned coating dispersion, and then spray 441.0 g of the coating liquid, Particles containing compound I were obtained.

[0068] Next, by the same method as in Comparative Example 1, compound I-containing granules, disintegrant-coated granules, and calcium stearate (NOF) were mixed and compressed to prepare...

Embodiment 2

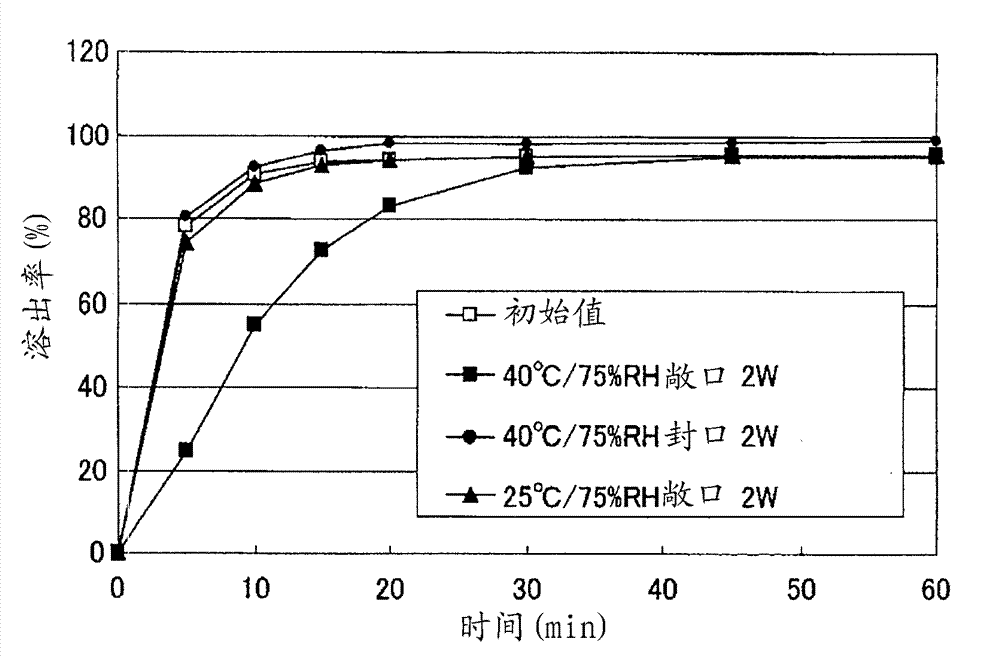

[0069] [Example 2] (Compared with Example 1, polyethylene glycol 6000 is half the amount)

[0070] Add 6.3 g of polyethylene glycol 6000 (NOF, trade name; polyethylene glycol 6000P) to 607.3 g of pure water and dissolve it, then add methacrylic acid copolymer LD (Ebonick, trade name; オイドラギット L30D55) 420g, fully stirred to prepare coating dispersion. Next, 70 g of D-mannitol (Mitsubishi Corporation Fudotec) was added and dissolved in 630 g of pure water to prepare a coating liquid.

[0071] Put 300 g of Compound I and 15.0 g of light anhydrous silicic acid (Floint Industries) into a microparticle coating and granulation device (Powrek, MP-01SFP), spray 984.0 g of the above-mentioned coating dispersion, and then spray 441.0 g of the coating liquid , to obtain particles containing compound I.

[0072] Next, by the same method as in Comparative Example 1, compound I-containing granules, disintegrant-coated granules, and calcium stearate (NOF) were mixed and compressed to prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com