Method for synthesizing P type zeolite from kaolin

A technology for kaolin and zeolite, which is applied in the field of synthesizing P-type zeolite from kaolin, can solve problems such as low cost of the synthesis process, and achieve the effects of low quality requirements, low energy consumption, and optimized process parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 3g of kaolin and mix it with 16ml of 4mol / L sodium hydroxide solution and put it into an autoclave. The high-pressure reactor was kept at 240°C for 3 hours and then cooled naturally to obtain activated kaolin. Then, the activated kaolin was dissolved in 100 ml of hydrochloric acid with a concentration of 1.2 mol / L, stirred and reacted for 0.5 h, and then filtered to obtain a kaolin acid hydrolysis solution. Use NaOH to adjust the pH of the kaolin acid solution to 10 to obtain active silicon-aluminum raw materials, mix it with 50 mL of NaOH solution with a concentration of 1 mol / L, and put it into a high-pressure reactor. After the high-pressure reactor was kept at 90° C. for 48 hours, it was washed and filtered to obtain P-type zeolite. Its calcium ion exchange capacity is 211mg CaCO 3 / g, the whiteness is 91.

Embodiment 2

[0023] Take 3g of kaolin and mix it with 16ml of 5mol / L sodium hydroxide solution and put it into the autoclave. The high-pressure reactor was kept at 190°C for 9 hours, and then cooled naturally to obtain activated kaolin. Then, the activated kaolin was dissolved in 40 ml of hydrochloric acid with a concentration of 3 mol / L, stirred and reacted for 0.5 h, and then filtered to obtain a kaolin acid hydrolysis solution. Use NaOH to adjust the pH of the kaolin acid hydrolysis solution to 3 to obtain active silicon-alumina raw materials, mix it with 50 mL of NaOH solution with a concentration of 1 mol / L, and put it into a high-pressure reactor. After the high-pressure reactor was kept at 90° C. for 48 hours, it was washed and filtered to obtain P-type zeolite. Its calcium ion exchange capacity is 280mg CaCO 3 / g, the whiteness is 69.

Embodiment 3

[0025] Take 3g of kaolin and mix it with 16ml of 6mol / L sodium hydroxide solution and put it into the autoclave. The high-pressure reactor was kept at 160°C for 24 hours and then cooled naturally to obtain activated kaolin. Then, the activated kaolin was dissolved in 30 ml of hydrochloric acid with a concentration of 4 mol / L, stirred and reacted for 0.5 h, and then filtered to obtain a kaolin acid hydrolysis solution. Use NaOH to adjust the pH of the kaolin acid hydrolysis solution to 14 to obtain active silicon-aluminum raw materials, mix it with 80 mL of NaOH solution with a concentration of 0.67 mol / L, and put it into a high-pressure reactor. After the high-pressure reactor was kept at 90° C. for 72 hours, it was washed and filtered to obtain P-type zeolite. Its calcium ion exchange capacity is 261mg CaCO 3 / g, the whiteness is 90.

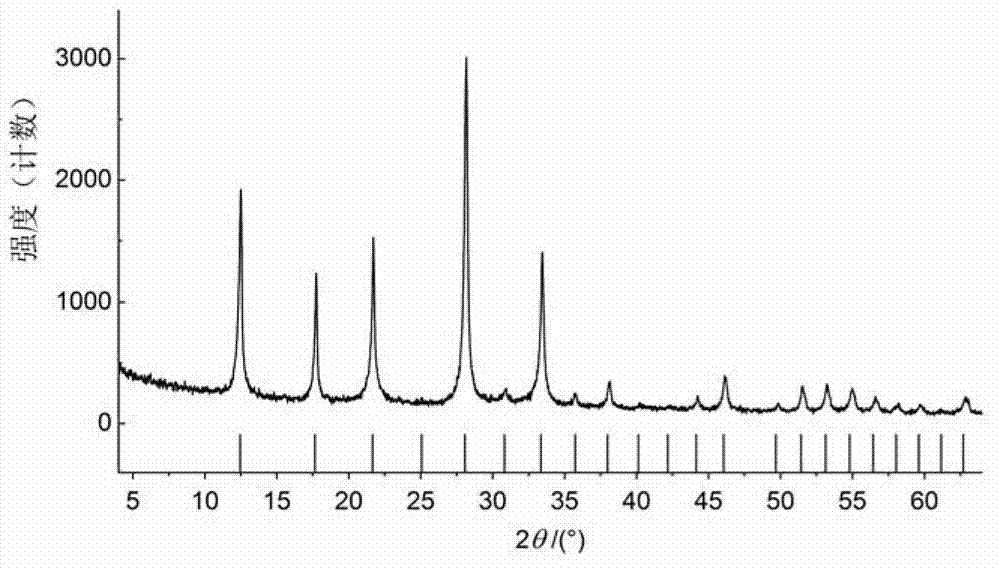

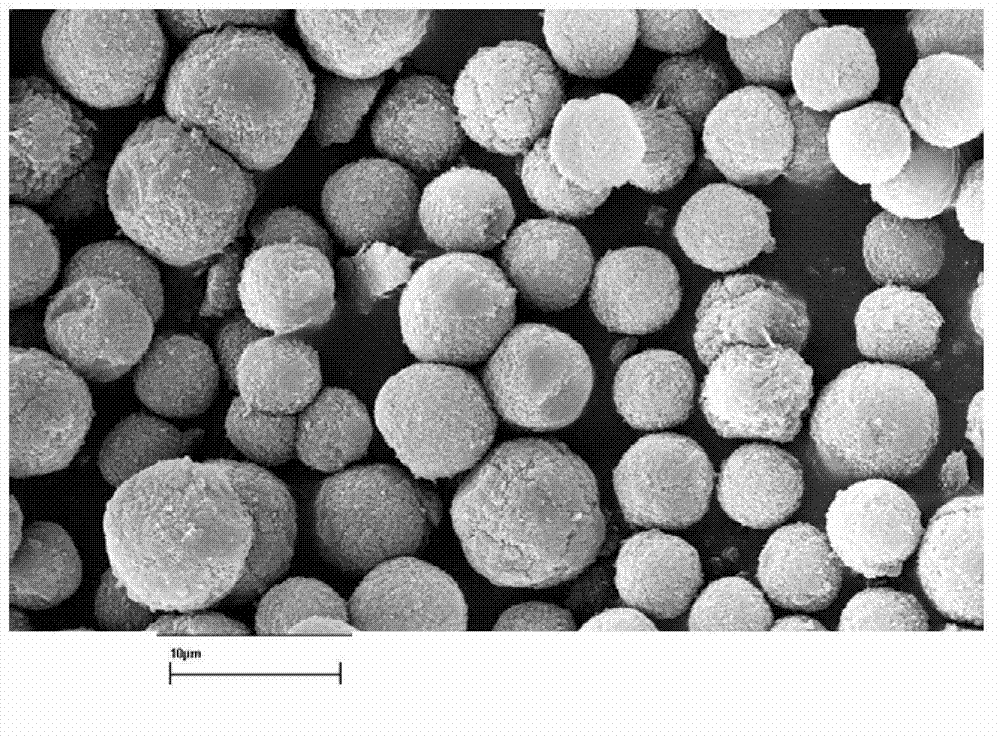

[0026] The embodiment of the present invention synthesizes the X-ray diffraction spectrum of P-type zeolite see figure 1 , the scanning el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com