Supported non-metallocene catalyst, preparation method and application

A non-metallocene, supported technology, applied in the field of non-metallocene catalysts, can solve the problems of complex preparation process, easy breakage, low catalyst polymerization activity, etc., and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

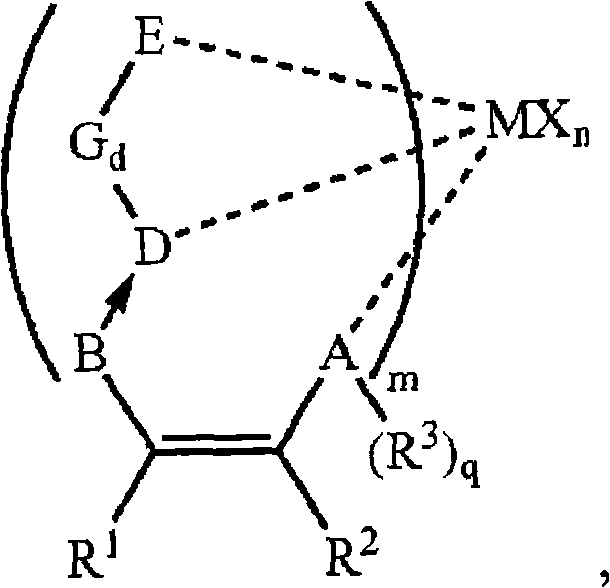

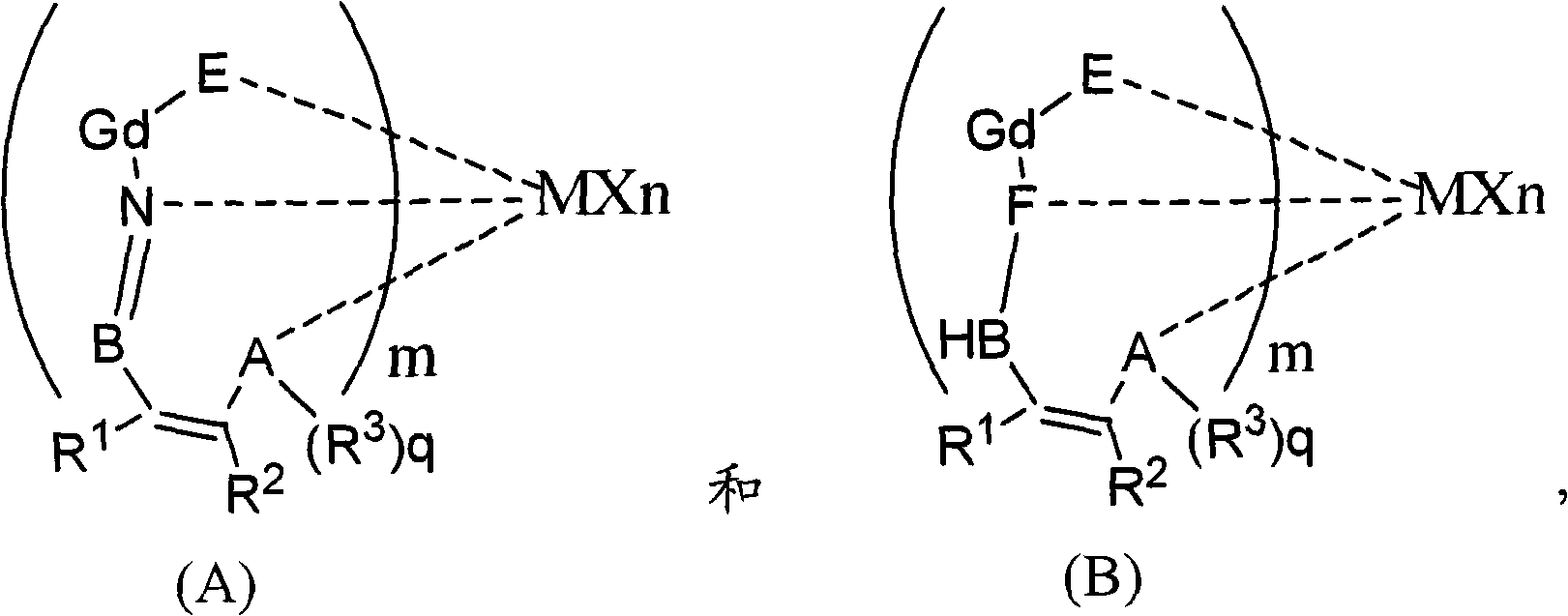

[0103] The present invention relates to a method for preparing a supported non-metallocene catalyst, comprising the following steps: dissolving a magnesium compound in a first solvent to obtain a magnesium compound solution; adding a precipitation agent to the magnesium compound solution to obtain a modified carrier The step of contacting the modified carrier with the non-metallocene complex in the presence of a second solvent to obtain a mixed slurry; the step of directly drying the mixed slurry to obtain a modified carrier; and the step of making a metal selected from the group IVB The step of reacting the chemical treatment agent of the compound with the modified support to obtain the supported non-metallocene catalyst.

[0104] The magnesium compound will be specifically described below.

[0105] According to the present invention, the term "magnesium compound" uses a common concept in the art, and refers to an organic or inorganic solid anhydrous magnesium-containing compound ...

Embodiment 1

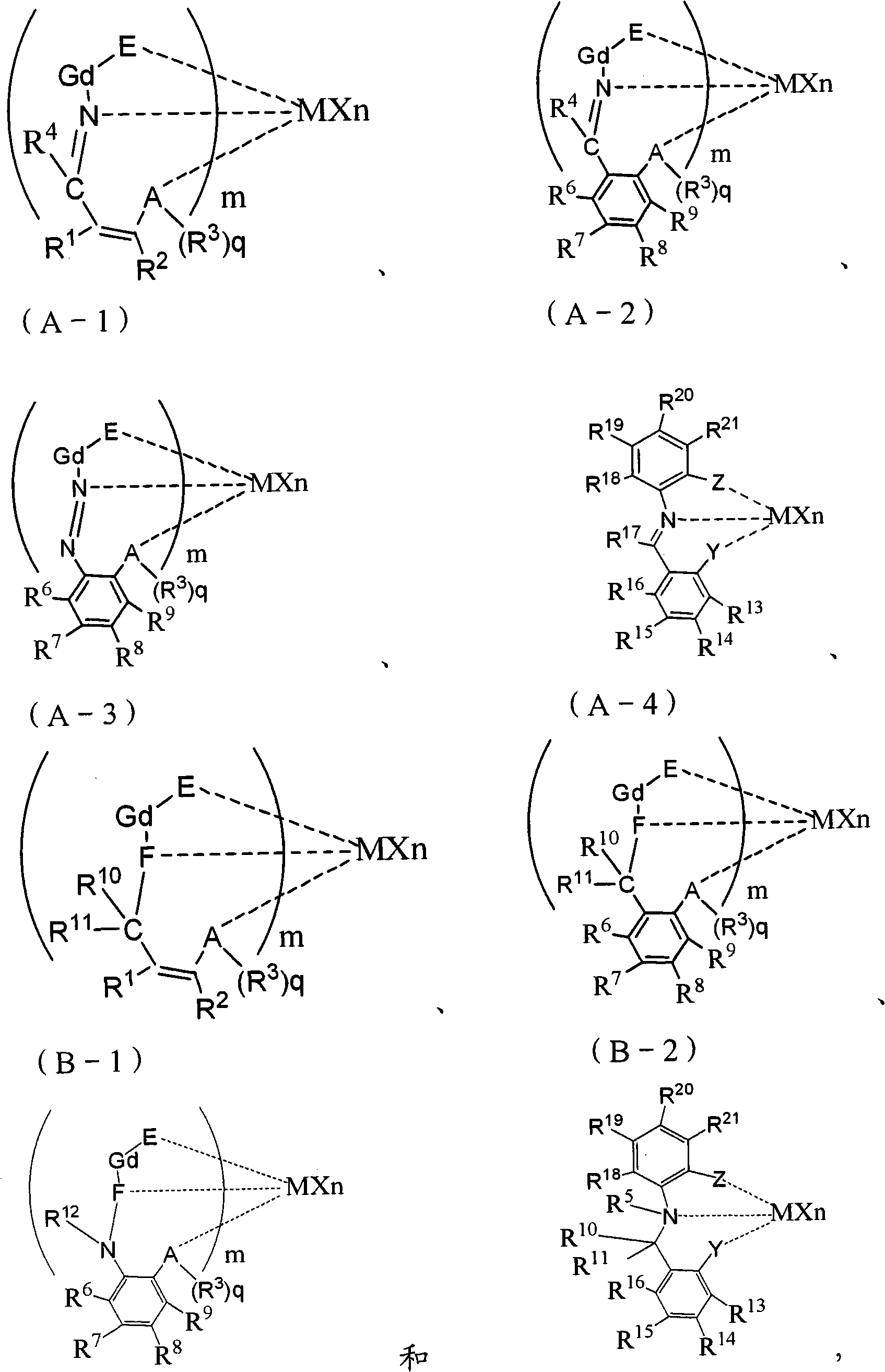

[0328] The magnesium compound uses anhydrous magnesium chloride, the first solvent uses tetrahydrofuran, the precipitation agent uses hexane, and the non-metallocene complex uses the structure The second solvent is dichloromethane, the chemical treatment agent of the IVB group metal compound is titanium tetrachloride, and the chemical treatment agent is hexane.

[0329] Weigh 5g of anhydrous magnesium chloride, add the first solvent and completely dissolve at room temperature to obtain the magnesium compound solution, then add the precipitating agent, stir and react at 60°C for 4 hours to completely precipitate, filter and wash the precipitant twice, each time The amount of precipitant is 60ml, and it is evenly heated to 60°C and vacuum-dried to obtain a modified carrier.

[0330] Then, the modified carrier is added to the solution formed by the non-metallocene complex and the second solvent, stirred at room temperature for 6 hours, and vacuum dried at room temperature to obtain th...

Embodiment 1-1

[0335] It is basically the same as embodiment 1, but has the following changes:

[0336] The first solvent is changed to toluene, the precipitation agent is changed to cyclohexane, and the non-metallocene complex is used The second solvent was changed to toluene, and the chemical treatment agent for group IVB metal compounds was changed to zirconium tetrachloride (ZrCl 4 ), the solvent for the chemical treatment agent is changed to cyclohexane.

[0337] The ratio of the magnesium compound to the first solvent is 1mol: 150ml; the molar ratio of the magnesium compound to the non-metallocene complex is 1:0.15; the volume ratio of the precipitation agent to the first solvent is 1:2; The molar ratio of chemical treatment agent based on IVB metal elements is 1:0.20.

[0338] The supported non-metallocene catalyst is referred to as CAT-1-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com