Fruit cuticle-imitated compression-resistant germproof packaging film and preparation method thereof

A cuticle and anti-bacterial technology, which is applied in the field of packaging materials, can solve the problems of not being able to effectively prolong the storage period of fruits and have no antibacterial properties, and achieve obvious hydrophobicity, prolong shelf life, and inhibit the growth of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

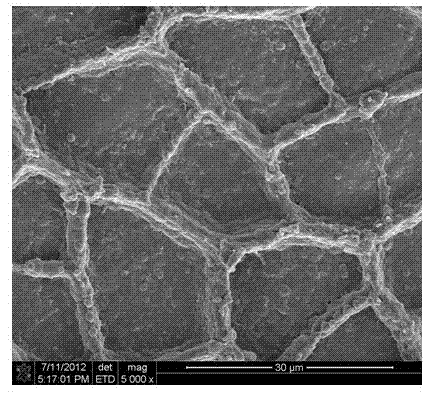

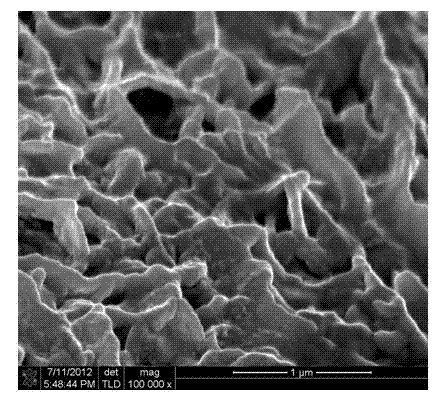

Image

Examples

Embodiment 1

[0043] Preparation method of imitation fruit cuticle anti-compression and anti-bacteria packaging film

[0044] (1) Preparation of konjac glucomannan base liquid: Add 5.0% paraffin and water into a beaker, place the beaker on a magnetic stirrer at 1000 r / min, heat to 75°C, stir to dissolve; use 1 mol / L NaOH Adjust the pH to 10, then add 10% of konjac glucomannan esterification modified product, 1% of chitosan, 0.12% of xanthan gum, 0.75% of carrageenan, and stir at 1000 r / min for 60 min;

[0045] (2) Preparation of synergist solution: take another beaker, mix 3% polycaprolactone (PCL), 0.5% epoxy soybean oil, 0.5% glycerin with water, heat at 1000 r / min to 55°C , stir evenly;

[0046] (3) Preparation of composite membrane solution: Add the prepared synergist solution into the konjac glucomannan base solution, place it on a magnetic stirrer (1000 r / min; 60°C) and stir continuously for 60 min, then, in Degas on a centrifuge (3500 r / min) for 30 min;

[0047] (4) The production...

Embodiment 2

[0053] Preparation method of imitation fruit cuticle anti-compression and anti-bacteria packaging film

[0054] (1) Preparation of konjac glucomannan base liquid: Add 5.5% paraffin and water into a beaker, place the beaker on a magnetic stirrer at 1000 r / min, heat to 80°C, stir to dissolve; use 1 mol / L NaOH Adjust the pH to 11, then add 20% of konjac glucomannan esterification modified product, 1.5% of chitosan, 0.15% of xanthan gum, 0.85% of carrageenan, and stir at 1000 r / min for 75 min;

[0055] (2) Preparation of synergistic solution: take another beaker, mix polycaprolactone (PCL) 4%, epoxidized soybean oil 1%, glycerin 1% with water, heat at 1000 r / min to 63°C , stir evenly;

[0056] (3) Preparation of composite membrane solution: The prepared synergist solution was added to the konjac glucomannan base solution, placed on a magnetic stirrer (1000 r / min; 63°C) and stirred continuously for 75 min. Next, degas for 45 min on a centrifuge (3500 r / min);

[0057] (4) The pro...

Embodiment 3

[0062] Preparation method of imitation fruit cuticle anti-compression and anti-bacteria packaging film

[0063] (1) Preparation of konjac glucomannan base solution: Add 6.5% paraffin and water into a beaker, place the beaker on a magnetic stirrer at 1000 r / min, heat to 85°C, stir to dissolve; use 1 mol / L NaOH Adjust the pH to 12, then add 25% of konjac glucomannan esterification modified product, 1.5% of chitosan, 0.18% of xanthan gum, 1% of carrageenan, and stir at 1000 r / min for 120 min;

[0064] (2) Preparation of synergistic solution: take another beaker, mix polycaprolactone (PCL) 5%, epoxidized soybean oil 1.5%, glycerin 1% with water, heat at 1000 r / min to 65°C , stir evenly;

[0065] (3) Preparation of composite membrane solution: Add the prepared synergist solution into the konjac glucomannan base solution, place it on a magnetic stirrer (1000 r / min; 65°C) and stir continuously for 120 min, then, in Degas for 45 min on a centrifuge (3500 r / min);

[0066] (4) Fabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com