Heat-curing heat-conduction heat-dissipation paint and preparation method thereof

A heat-dissipating coating and heat-curing technology, applied in coating and other directions, can solve problems such as energy consumption and environmental pollution, and achieve the effects of production cost control, good flame retardant insulation, and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

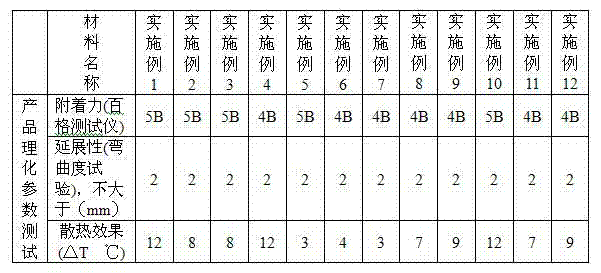

Examples

Embodiment 1

[0022] Take 30% of acrylic resin, 30% of nitrocellulose resin, 15% of solvent, 2% of auxiliary agent, 3% of dyeing agent, 20% of copper powder, and the average particle size of copper powder is 1 micron.

[0023] The solvent components are butyl acetate, n-butanol and ethyl cellosolve, and the mass ratio of the components in the mixed solvent is 2:2:1.

[0024] The auxiliary agent includes a defoamer and a leveling agent, the mass ratio of the defoamer and the leveling agent is 1:1, wherein the defoamer is a silicone defoamer, and the leveling agent is an organic fluorine leveling agent.

[0025] Mix all butyl acetate, n-butanol and ethyl cellosolve evenly, and dissolve all acrylic resin and nitrocellulose resin in the above mixed solvent to form a resin solution. Take all the resin solution in the above steps, mix it with the dyeing agent, and stir it evenly at room temperature at 800-1000 rpm to form a paint; pour the paint in the above steps into a sand mill to grind a...

Embodiment 2

[0028] Prepare 30% of acrylic resin, 30% of nitrocellulose resin, 15% of solvent, 2% of additives, 3% of carbon black, 20% of boron nitride, and the average particle size of boron nitride is 3 microns.

[0029] The solvent is butyl acetate, n-butanol, and ethyl cellosolve, and the mass-to-component ratio is 2:2:1.

[0030] The auxiliary agent includes a defoamer and a leveling agent, the mass ratio of the defoamer and the leveling agent is 1:1, wherein the defoamer is a silicone defoamer, and the leveling agent is an organic fluorine leveling agent.

[0031] Mix all butyl acetate, n-butanol and ethyl cellosolve evenly, and dissolve all acrylic resin and nitrocellulose resin in the above mixed solvent to form a resin solution. Take all the resin solution in the above steps, mix it with the dyeing agent, and stir it evenly at room temperature at 800-1000 rpm to form a paint; pour the paint in the above steps into a sand mill to grind and disperse until the fineness reaches 5 mi...

Embodiment 3

[0034] Prepare 30% of acrylic resin, 30% of nitrocellulose resin, 15% of solvent, 2% of additives, 3% of carbon black, 20% of aluminum nitride, and the average particle size of aluminum nitride is 3 microns.

[0035] The solvent is butyl acetate, n-butanol, and ethyl cellosolve, and the mass-to-component ratio is 2:2:1.

[0036] The auxiliary agent includes a defoamer and a leveling agent, the mass ratio of the defoamer and the leveling agent is 1:1, wherein the defoamer is a silicone defoamer, and the leveling agent is an organic fluorine leveling agent.

[0037] Mix all butyl acetate, n-butanol and ethyl cellosolve evenly, and dissolve all acrylic resin and nitrocellulose resin in the above mixed solvent to form a resin solution. Take all the resin solution in the above steps, mix it with the dyeing agent, and stir it evenly at room temperature at 800-1000 rpm to form a paint; pour the paint in the above steps into a sand mill to grind and disperse until the fineness reaches...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com