Grain groove cooling bed machine

A cooling bed and grain trough technology, applied in the preparation of alcoholic beverages, etc., can solve problems such as pollution, poor production efficiency, and difficult temperature control, and achieve good results, obvious production efficiency, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following examples illustrate the present invention in detail.

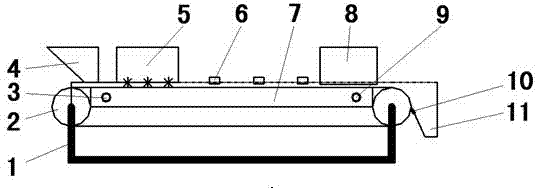

[0012] see figure 1 , a structural schematic diagram of a grain trough cooling machine, a grain trough cooling machine, including a frame 1, a belt transmission system 2, a feed port 4, a discharge port 11, a mixing machine 5, and a koji adding machine 8. The belt transmission system 2 is installed on the frame 1, and the feeding port 4, the mixing machine 5, the koji adding machine 8 and the discharge port 11 are successively installed above the belt transmission system 2. A water tank 7 is installed in the middle of the belt transmission system, a water inlet 3 is provided at the front of the water tank 7, and a water outlet 9 is provided at the rear; three temperature detectors are installed between the mixer 5 and the koji adding machine 8 Device 6. A brush 10 is installed at the contact between the discharge port 11 and the belt transmission system 2 .

[0013] When the hot cooked material is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com