Low-voltage tube bus duct power distribution system

A technology of power distribution system and bus duct, applied in electrical components and other directions, can solve the problems of difficult to guarantee reliability, short service life, large current loss, etc., and achieve the effect of concise overall structure, long service life and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

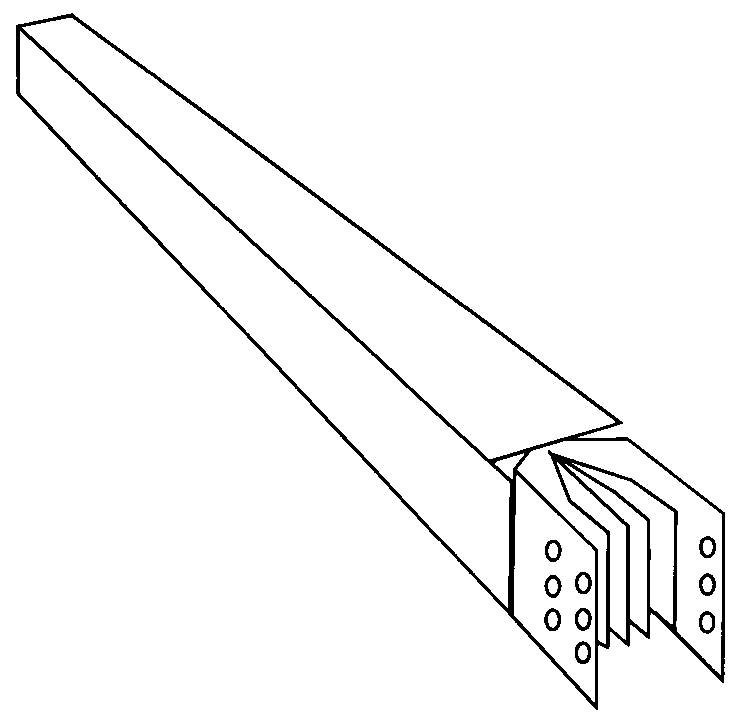

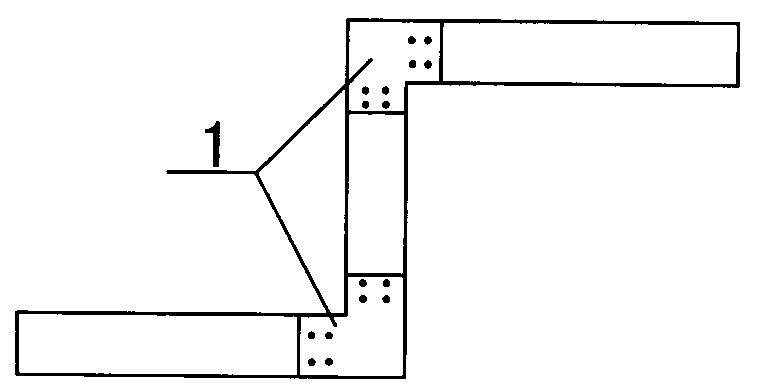

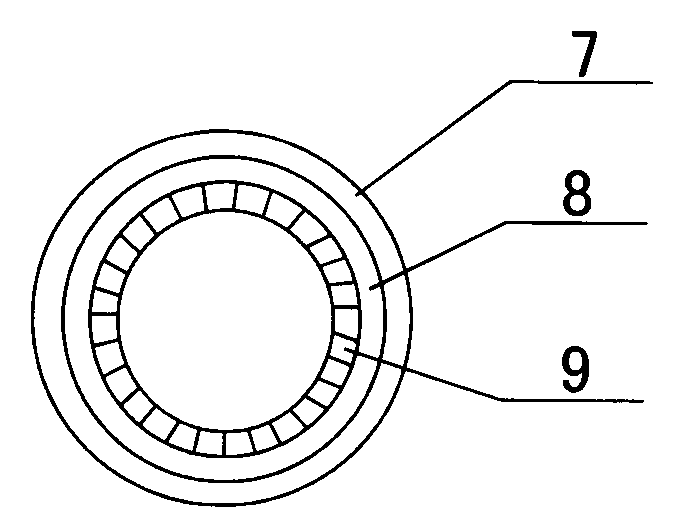

[0018] Such as image 3 , Figure 4 , Figure 5 , Image 6 As shown, the low-voltage pipe busway power distribution system is composed of busbar 1, multi-channel pipe busbar connector 2, distribution box 3, embedded connector 4, and mounting bracket 5; busbar 1 is composed of shell 7, insulating layer 8 and Composed of conductor 9, shell 7 and insulating layer 8 are set or sprayed on the surface of conductor 9; busbar 1 adopts multi-channel pipe busbar connector 2 and embedded connector 4 for tap installation; busbar 1 is fixed on the wall through mounting bracket 5 On the busbar 1, a distribution box 3 is installed as required.

[0019] During installation, the busbar 1 can be bent and processed arbitrarily according to the installation needs; when dividing the lines, use the multi-channel pipe busbar connector 2 to carry out the dividing line connection, and divide the lines into multiple channels; in special occasions, use 4 pairs of embedded connectors The busbar 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com