Method for preparing nitrogen-doped photo-catalytic material containing gallium oxide at low temperature

A photocatalytic material, a technology of gallium oxide, applied in the field of low-temperature preparation of nitrogen-doped gallium-containing oxide photocatalytic materials, can solve the problems of mesoporous structure collapse and difficulty in preparing mesopores, and improve solar energy utilization rate and photocatalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

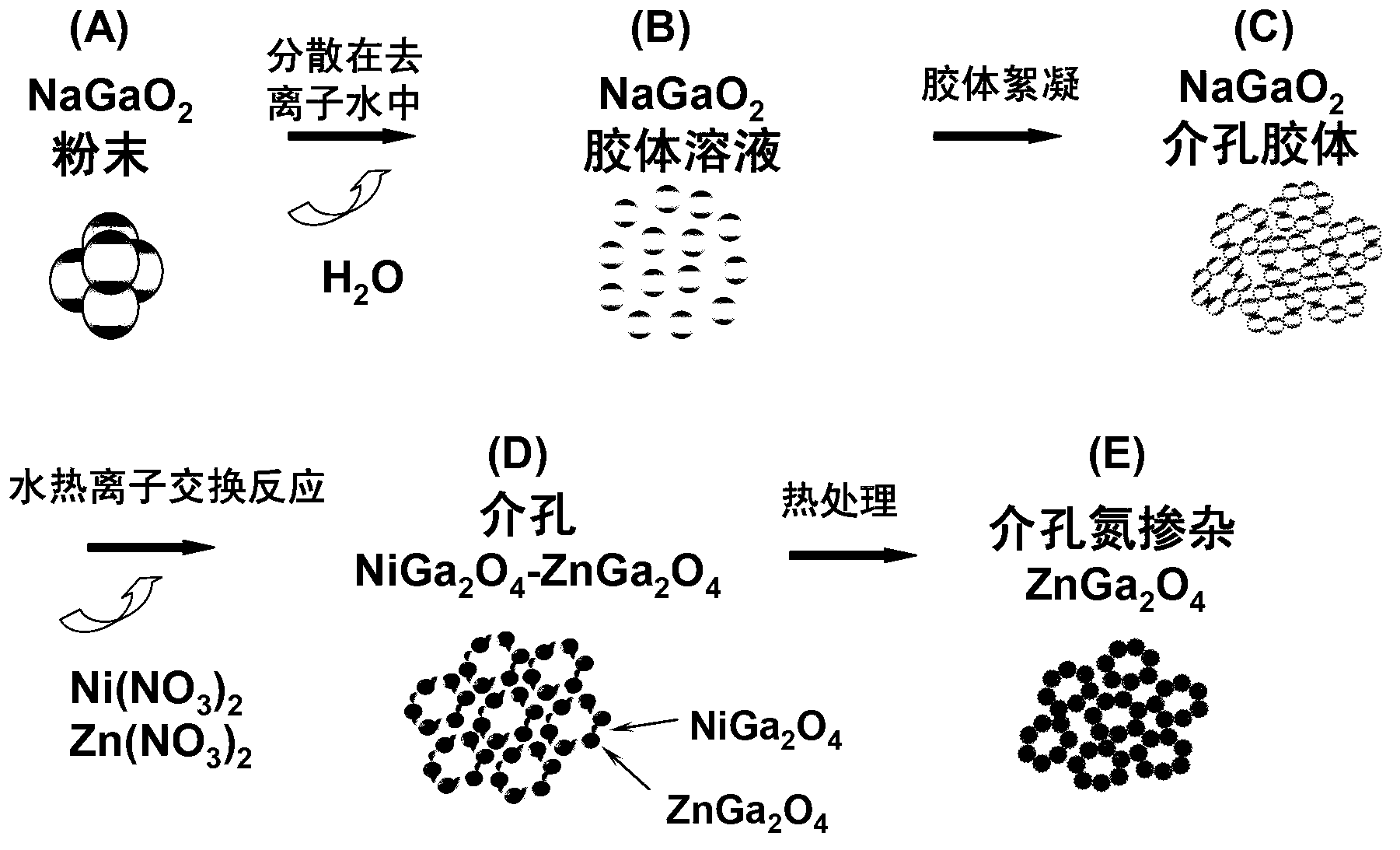

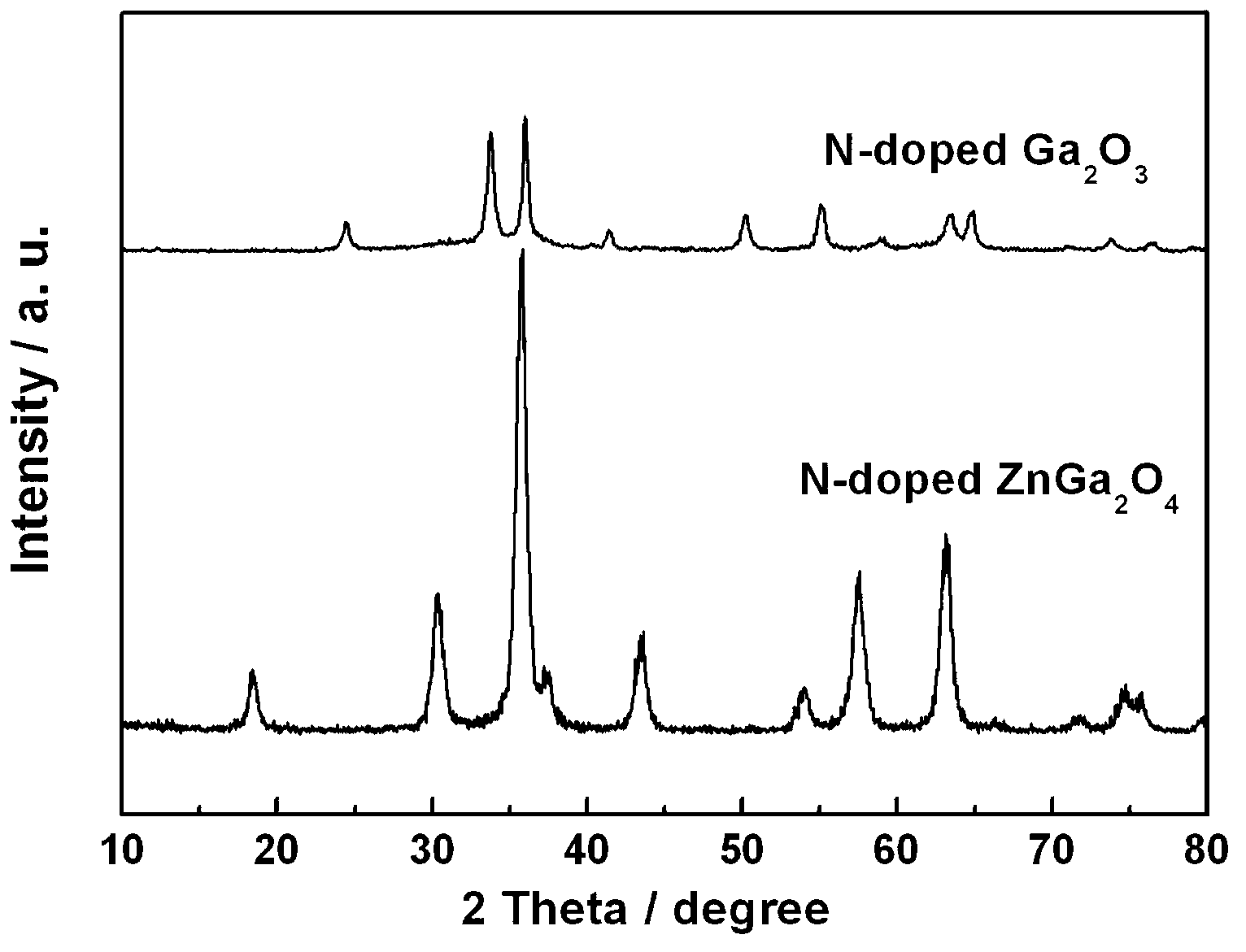

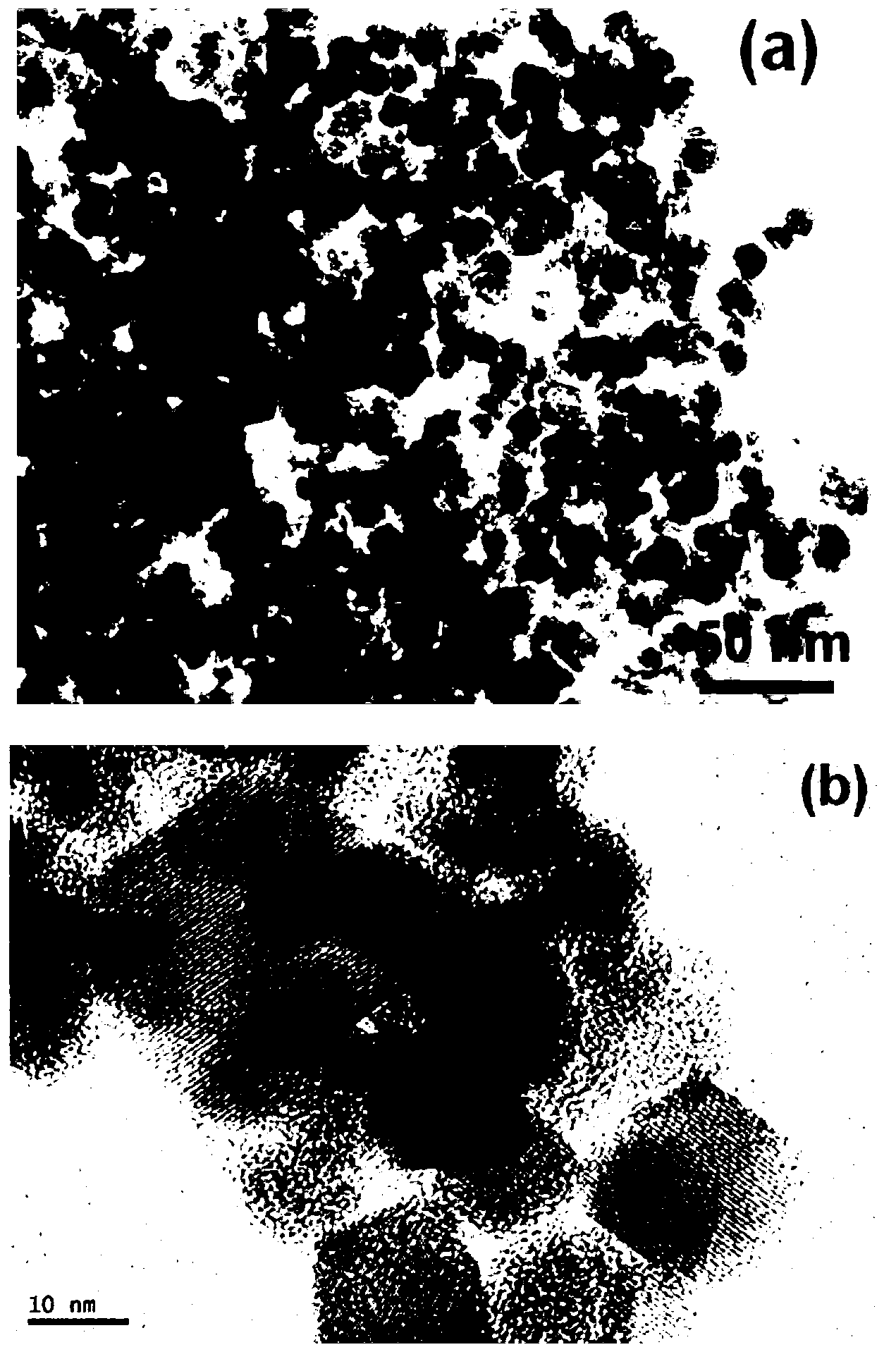

[0032] Nitrogen doped mesoporous ZnGa 2 o 4 Preparation: Dissolve 0.2494g of sodium gallate powder in 15mL of deionized water, weigh 0.0145g of nickel nitrate and 0.2680g of zinc nitrate, dissolve in 15mL of deionized water, then pour 15mL of nickel nitrate and nitric acid solution into 15mL of gallium Sodium acid sodium solution, the mixed solution was stirred and reacted at room temperature for 0.5h, put into a 40mL hydrothermal kettle, and hydrothermally treated at 200°C for 3h, naturally cooled to room temperature, centrifuged and dried, and placed in a muffle furnace for 400 °C heat treatment for 30min to obtain nitrogen-doped mesoporous ZnGa 2 o 4 photocatalytic material. X-ray powder diffraction results show that the obtained sample is a spinel phase ZnGa 2 o 4 . TEM image showing ( image 3 a), the resulting ZnGa 2 o 4 The sample has a worm-like mesoporous structure, and the mesoporous structure is formed by the accumulation of 5-10nm nanoparticles. High-reso...

Embodiment 2

[0034] Nitrogen doped mesoporous ZnGa 2 o 4 Preparation: Dissolve 0.2494g of sodium gallate powder in 15mL of deionized water, weigh 0.0291g of nickel nitrate and 0.2673g of zinc nitrate, dissolve in 15mL of deionized water, then pour 15mL of nickel nitrate and nitric acid solution into 15mL of gallium Sodium acid sodium solution, the mixed solution was stirred and reacted at room temperature for 0.5h, put into a 40mL hydrothermal kettle, and hydrothermally treated at 200°C for 3h, naturally cooled to room temperature, centrifuged and dried, and placed in a muffle furnace for 400 °C heat treatment for 30min to obtain nitrogen-doped mesoporous ZnGa 2 o 4 photocatalytic material.

Embodiment 3

[0036] Nitrogen doped mesoporous ZnGa 2 o 4 Preparation: Dissolve 0.2494g of sodium gallate powder in 15mL of deionized water, weigh 0.0291g of nickel nitrate and 0.2673g of zinc nitrate, dissolve in 15mL of deionized water, then pour 15mL of nickel nitrate and nitric acid solution into 15mL of gallium Sodium acid sodium solution, the mixed solution was stirred at room temperature for 1 hour, put it into a 40mL hydrothermal kettle, and treated it at 180°C for 5 hours, cooled naturally to room temperature, centrifuged and dried, and placed in a muffle furnace at 450° C heat treatment for 30min to obtain nitrogen-doped mesoporous ZnGa 2 o 4 photocatalytic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com