Grinding process for grinding heat transfer printing color paste

A grinding process and thermal transfer printing technology, applied in grain processing, etc., can solve the problems of high temperature of color paste and equipment, difficulty in ensuring stable product quality, and increased difficulty in heat dissipation, so as to achieve good transparency, improve heat dissipation effect, and hue stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 (this example is the embodiment of grinding device)

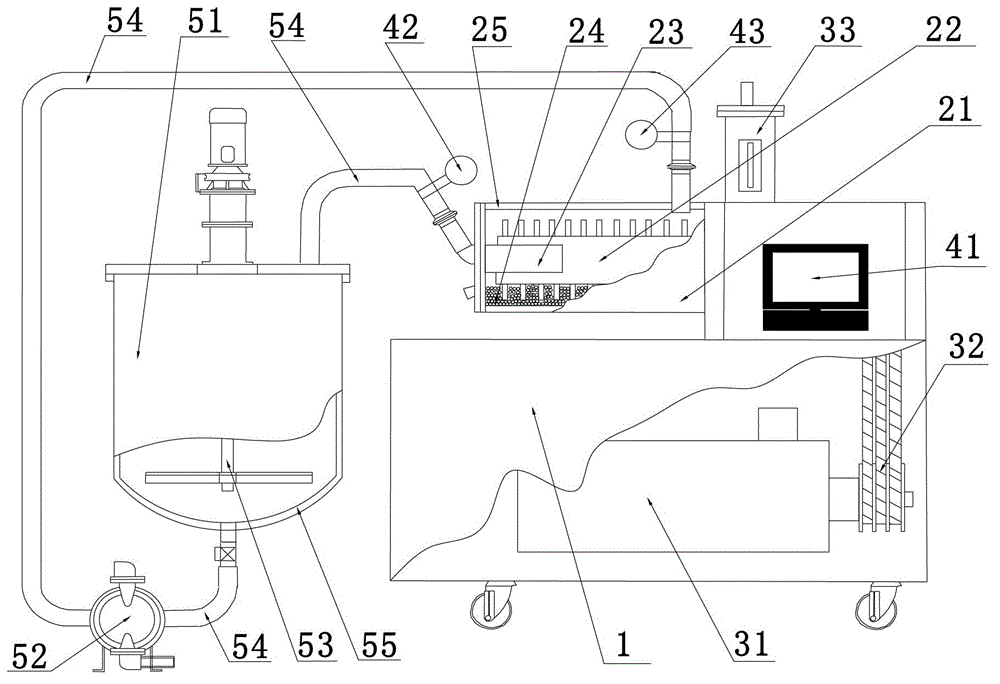

[0032] A grinding device for preparing thermal transfer printing paste, comprising a base support 1, on which a sand mill, control components and power components are fixed, the sand mill has a grinding bucket 21, and a stirring bucket 21 is arranged in the grinding bucket. Device 22, a separator 23, and several grinding media 24. The grinding device is also provided with a circulation assembly, which includes a circulation barrel 51, a circulation pump 52, and several conduits 54, and an agitator 53 is arranged in the circulation barrel. The discharge port of the grinding bucket 21 communicates with the feed port of the circulation bucket 51 through a conduit 54, and the feed port of the grinding bucket and the discharge port of the circulation bucket are respectively connected to the outlet and the inlet of the circulation pump by conduits. The circulating pump 52 can choose different pumps according ...

Embodiment 2

[0040] Embodiment 2 (this example is the embodiment of thermal transfer printing paste grinding)

[0041] 1. According to the attached figure 1 As shown, the grinding device in the grinding device embodiment described above is installed and cleaned.

[0042] 2. Take 4.086kg of pigment, 2.352kg of dispersant, 0.851kg of additive, and 7.711kg of distilled water, and stir for 2 hours with a dispersing high-speed machine to prepare a mixed solution. The viscosity of the mixed solution is 586cps, and set aside.

[0043] 3. Fill the dried grinding medium into the grinding barrel; the grinding medium is cerium-stabilized zirconia beads with a true circle surface and no pores, the particle size is 0.6~0.8mm, and the grinding medium is in the The filling rate in the grinding bucket is 80%.

[0044] 4. Pump the mixed solution dispersed in step 2 into the circulation barrel, turn on the cooling device and the stirring device in the circulation barrel, and ensure that the refrigerant fo...

Embodiment 3

[0048] Embodiment 3 (this example is the embodiment of thermal transfer printing paste grinding)

[0049] This embodiment is basically the same as Embodiment 2, and its difference is:

[0050] The viscosity of the mixed solution in step 2 is 400cps, standby.

[0051] The grinding medium in step 3 is yttrium-stabilized zirconia beads with a particle size of 0.05-0.6mm, and the filling rate of the grinding medium in the grinding bucket is 70%.

[0052] In step 5, the grinding speed is controlled at 1000r / min, and the flow rate of the color paste is controlled at (0.5±0.2) kg / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com