Talc ore beneficiation method and talc ore beneficiation device

A beneficiation method and talc technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of large dust and noise, and achieve the effect of reducing noise, eliminating the harm of dust and prolonging working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

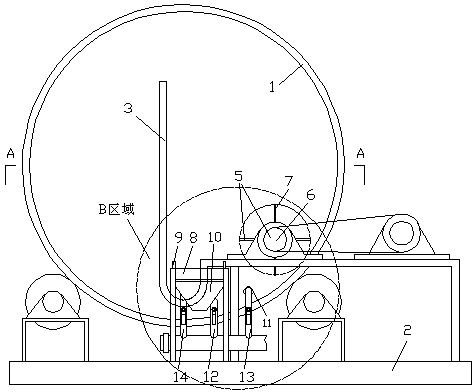

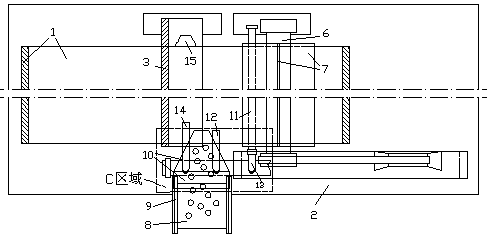

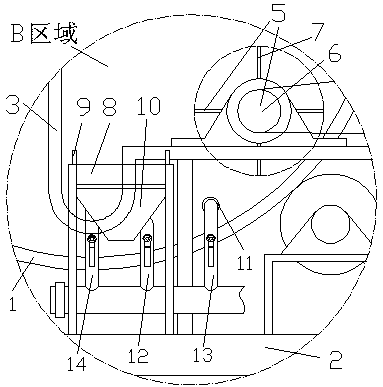

[0031] The method and device of the present invention will be further described and supplemented below in conjunction with the accompanying drawings and specific embodiments.

[0032] like figure 1 , 2As shown, the large horizontal drum 1 is made of a steel plate, and the large horizontal steel drum is placed on its support 2. The two ends of the support are uneven, so that the feeding end of the large drum is slightly higher than the discharging end. An inclination angle of 5-30° can be formed between its longitudinal axis and the ground plane. On the bearing, drive motor and speed reducer are arranged in addition (because it is not the main content of the invention, it is omitted in the figure). It is divided into left and right parts. The lower part of one side of the baffle is provided with a feed inlet 4, and the other side is provided with a separation scraper 5. The scraper adopts an impeller structure and is composed of a rotating shaft 6 and more than two blades 7. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com