Preparation method and application of PDMS polymer chip of arc-shaped concave aperture

A technology of arc-shaped depressions and polymers, applied in biochemical equipment and methods, animal cells, vertebrate cells, etc., can solve the problems of high price and complicated operation, and achieve the effect of simple operation and low experimental cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

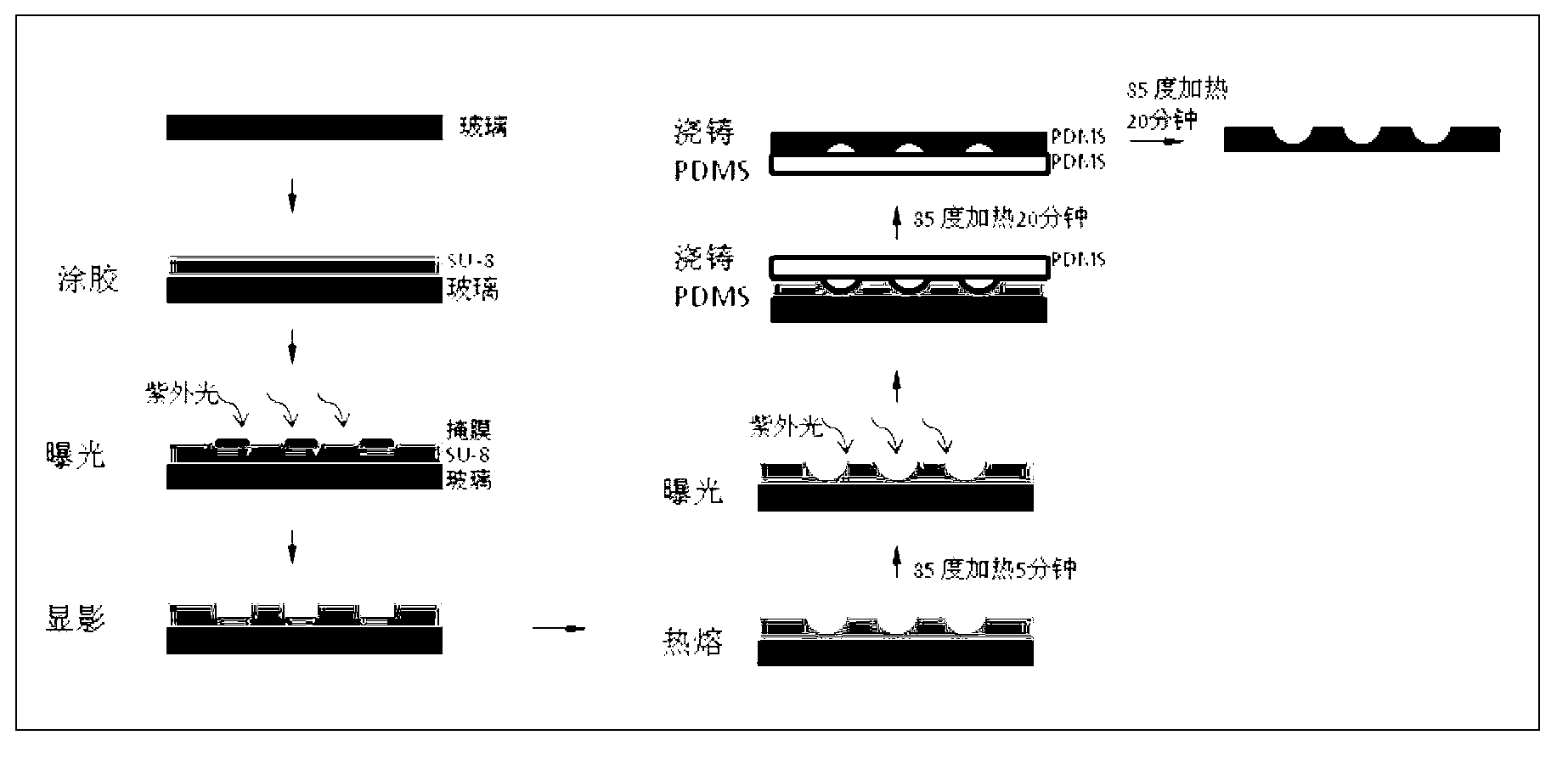

[0031] The SU-8 polymer template is made by photolithography technology, the template is a 20×20 circular hole, and the structure of the template is cylindrical. like figure 1 As shown, apply the SU-8 photoresist on a clean glass slide, heat it at 95 degrees Celsius for 1 hour; put the designed mask on and expose it to ultraviolet light for 60 seconds; heat it at 95 degrees Celsius for 15 minutes, and develop it for 5 minutes. Heat curing at 80°C for 2 hours; full exposure for 90 seconds. Uncured PDMS (10:1) was poured over the SU-8 polymer template and heated at 80 °C for 20 min at the same time. After the device is cooled, the upper PDMS chip is peeled off to form a counter-mold. Pour the uncured PDMS (10:1) onto the PDMS polymer anti-mold chip and heat it at 80°C for 20 minutes at the same time. After the device cools down, the upper layer of PDMS polymer can be peeled off to form arc-shaped arc-shaped concave holes. PDMS polymer chip.

Embodiment 2

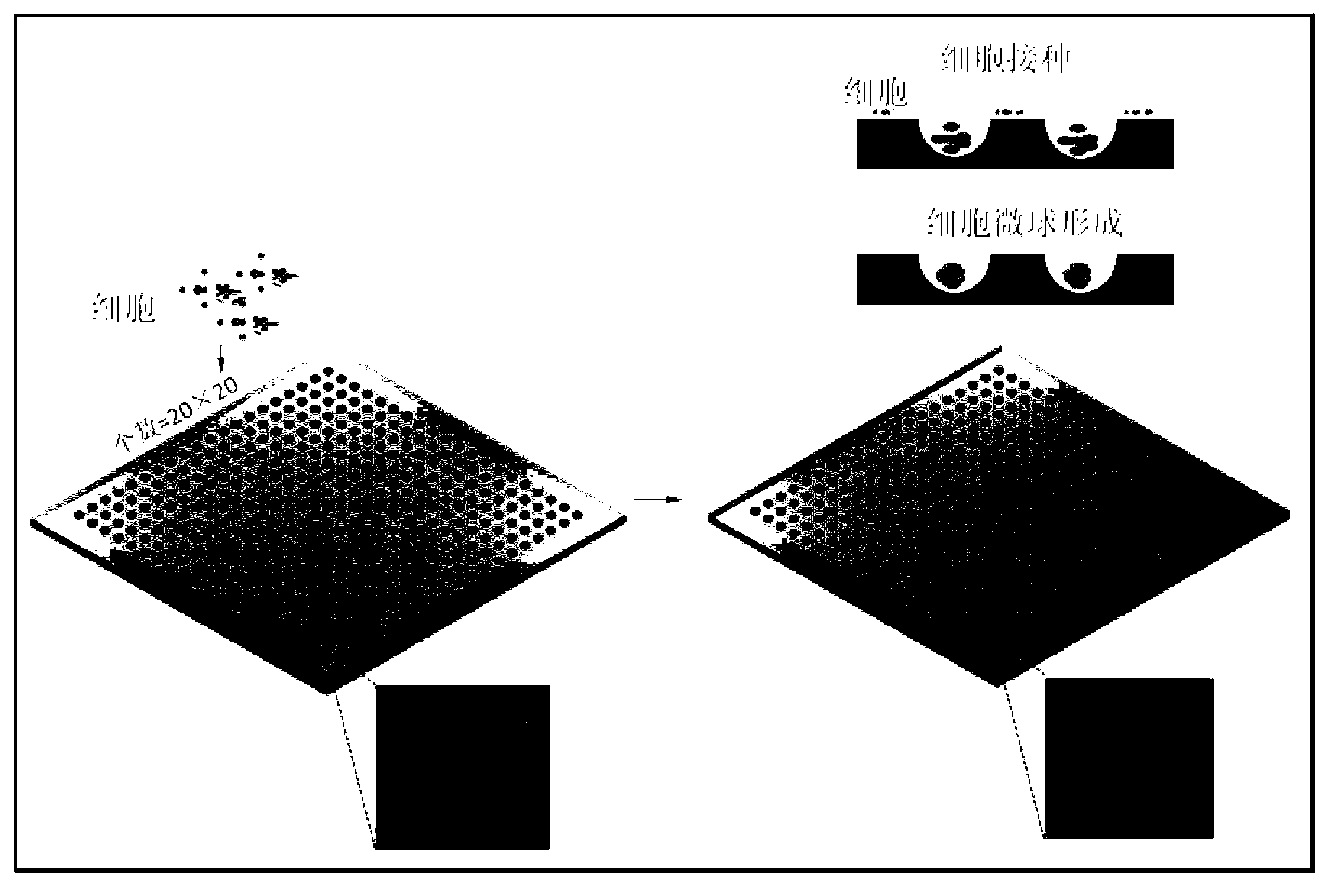

[0033] The principle and flow chart of the three-dimensional culture of rat chondrocytes on the PDMS polymer chip with curved concave holes figure 2 shown. The PDMS polymer chip with arc-shaped concave holes is first sterilized, irradiated with ultraviolet light overnight, and then modified with 1% PF-127 solution for 8 hours, inoculated with chondrocyte suspension, and the chondrocytes are under the action of gravity. It will settle to the bottom of the small well on the surface of the chip and spontaneously form a three-dimensional cell cluster.

Embodiment 3

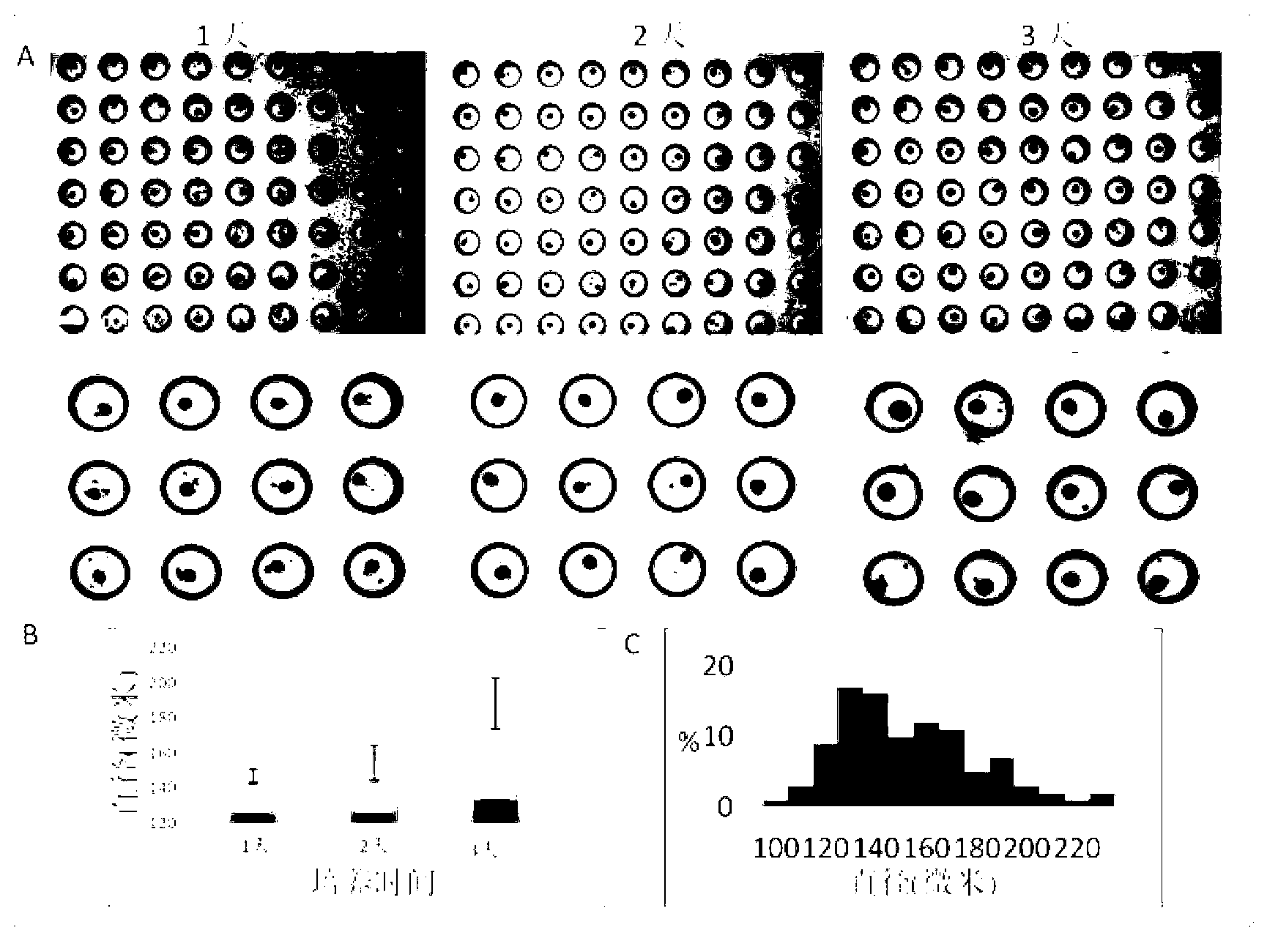

[0035] Based on SU-8 as a template, the rapid fabrication of arc-shaped concave small-hole PDMS polymer chip was used for three-dimensional culture of rat chondrocytes, and the maintenance of subtype and function. image 3 It shows the growth of rat chondrocytes cultured on the PDMS polymer chip with arc-shaped concave holes for three days. The connection between cells is getting tighter and the tendency of clustering is obvious. This proves that the arc-shaped PDMS polymer chip with concave holes can form a three-dimensional cell structure. Figure 4It shows the immunofluorescence staining of type II collagen after the mouse chondrocytes were cultured on the PDMS polymer chip with arc-shaped concave holes for three days. The control group was two-dimensional rat chondrocytes cultured in the well plate. The expression of type Ⅱ collagen in rat chondrocytes was obvious. Figure 5 It shows the photo of immunofluorescent staining of proteoglycan after three days of culture of mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com