High malt syrup and method for improving acarbose fermentation unit by using high malt syrup

A technology of high maltose syrup and high maltose syrup, which is applied in the field of medicine to achieve the effect of improving the biosynthesis and metabolism of acarbose, improving the fermentation index, and improving the fermentation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

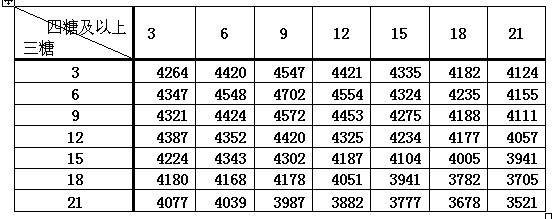

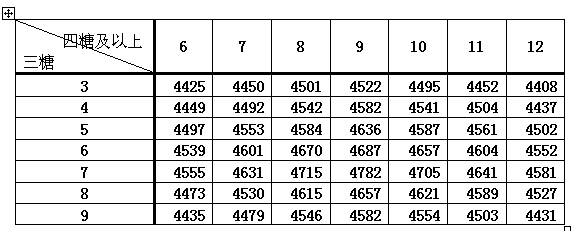

[0021] Example 1 Orthogonal experiments were used to explore the appropriate proportion of high maltose syrup components fermented by acarbose actinomycetes, and a suitable proportion of high maltose syrup trisaccharides, tetrasaccharides and more than tetrasaccharides was obtained.

[0022] The step that described orthogonal experiment optimizes the high maltose syrup component ratio in the fermentation medium of acarbose actinomycetes is:

[0023] (1) Prepare high maltose syrup containing trisaccharides, tetrasaccharides and more than four sugars in different proportions and with a glucose content of 0. Use different proportions of syrup and pure maltose to prepare high maltose syrup with a trisaccharide ratio of 3-21%, tetrasaccharide and tetrasaccharide ratios of 3-21%, and make trisaccharide, tetrasaccharide and tetrasaccharide in high maltose syrup Orthogonal experiment on the influence of components above sugar on the fermentation unit (the ratio of sugar is the chromat...

Embodiment 2

[0030] Example 2 Utilizing high maltose syrup to increase the fermentation unit of acarbose

[0031] Use different high maltose syrups to verify the fermenter (the volume of the seed tank is 1000L, the volume of the fermenter is 6200L, and the feeding amount is proportional to the formula)

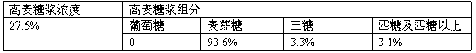

[0032] 3. Composition of high maltose syrup:

[0033]

[0034] ; 3 groups of parallel experiment results:

[0035] Numbering fermentation unit 1 4258 2 4223 3 4290 average 4257

[0036] 2. Composition of high maltose syrup:

[0037]

[0038] ; 3 groups of parallel experiment results:

[0039] Numbering fermentation unit 1 4345 2 4332 3 4325 average 4334

[0040] 3. Composition of high maltose syrup:

[0041]

[0042] ; 3 groups of parallel experiment results:

[0043] Numbering fermentation unit 1 3879 2 3869 3 3871 average 3873

[0044] 4. Composition of high maltose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com