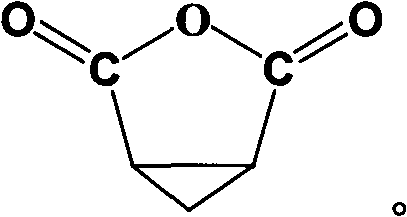

Nonaqueous electrolyte solution for improving lithium ion battery cycling stability

A non-aqueous electrolyte, cycle stability technology, applied in the field of chemical materials, can solve problems affecting battery performance, increase interface impedance, film composition and property changes, etc., to improve capacity retention and cycle life, increase cycle life and use The effect of improving the service life and capacity maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be described in detail below in conjunction with the embodiments.

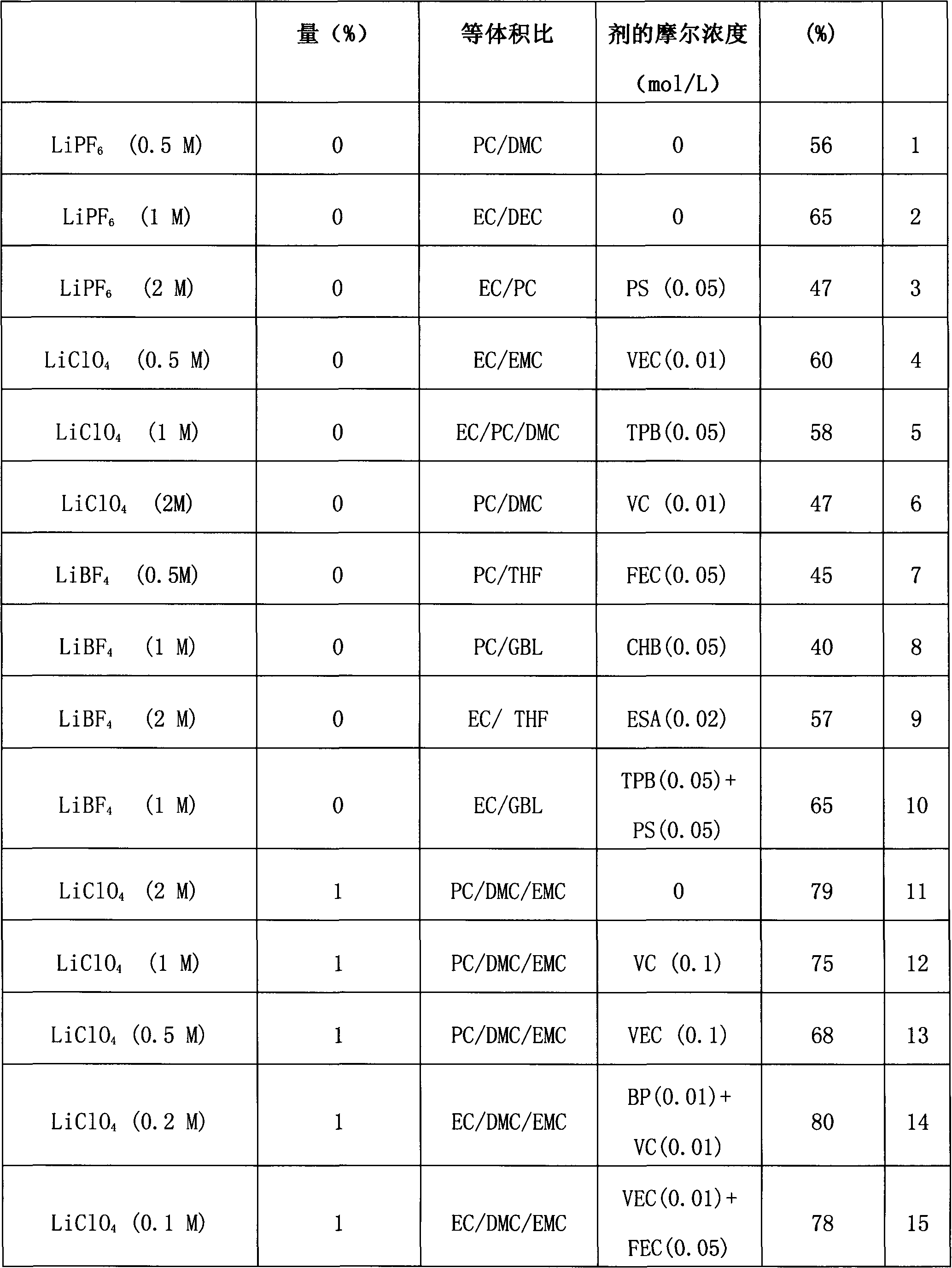

[0016] The present invention lists the composition of 1 to 47 kinds of non-aqueous electrolyte solutions and the test data of the capacity retention rate of the battery using each electrolyte solution in the form of a table, see Table 1 below for details. Among them, the first 10 embodiments are comparative examples without adding component B; the 1st to 33rd embodiments are 500 cycle battery capacity percentages at normal temperature, and the 34th to 47th embodiments are 500 cycles at 60°C. Cycle cycle battery capacity percentage.

[0017] Table 1 Components of non-aqueous electrolyte solution and percentage of battery capacity

[0018]

[0019]

[0020]

[0021]

[0022] It can be seen from the above examples that by using the above-mentioned non-aqueous electrolyte solution containing 2,3-cycloethane-1,4-butyrolactone, the capacity ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com