Method for preparing novel ruminant feed by using beneficial bacteria and plant fiber

A ruminant and plant fiber technology, applied in animal feed, animal feed, applications, etc., can solve the problems of high fiber content, low nutritional value, and environmental pollution, and achieve high protein content, rich nutrition, and low crude fiber content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

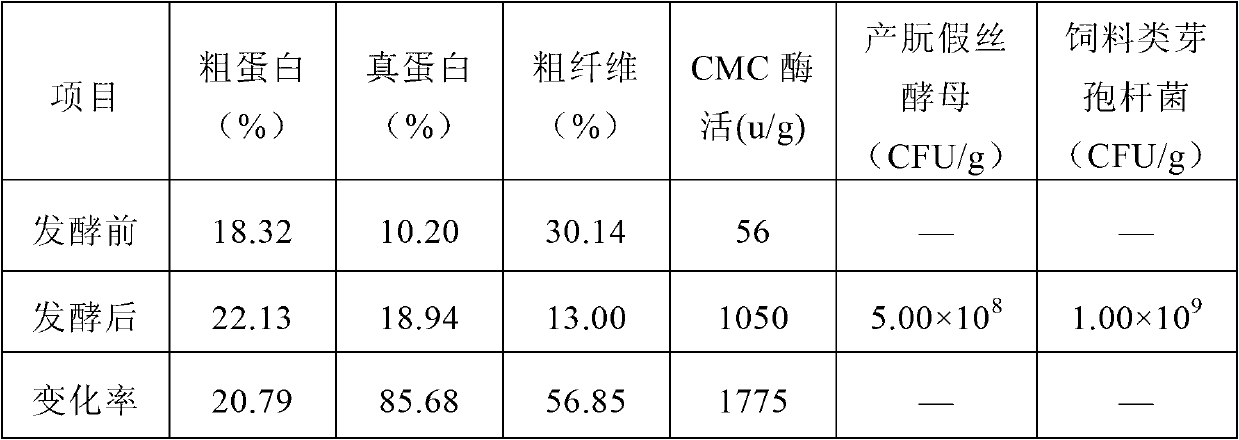

Embodiment 1

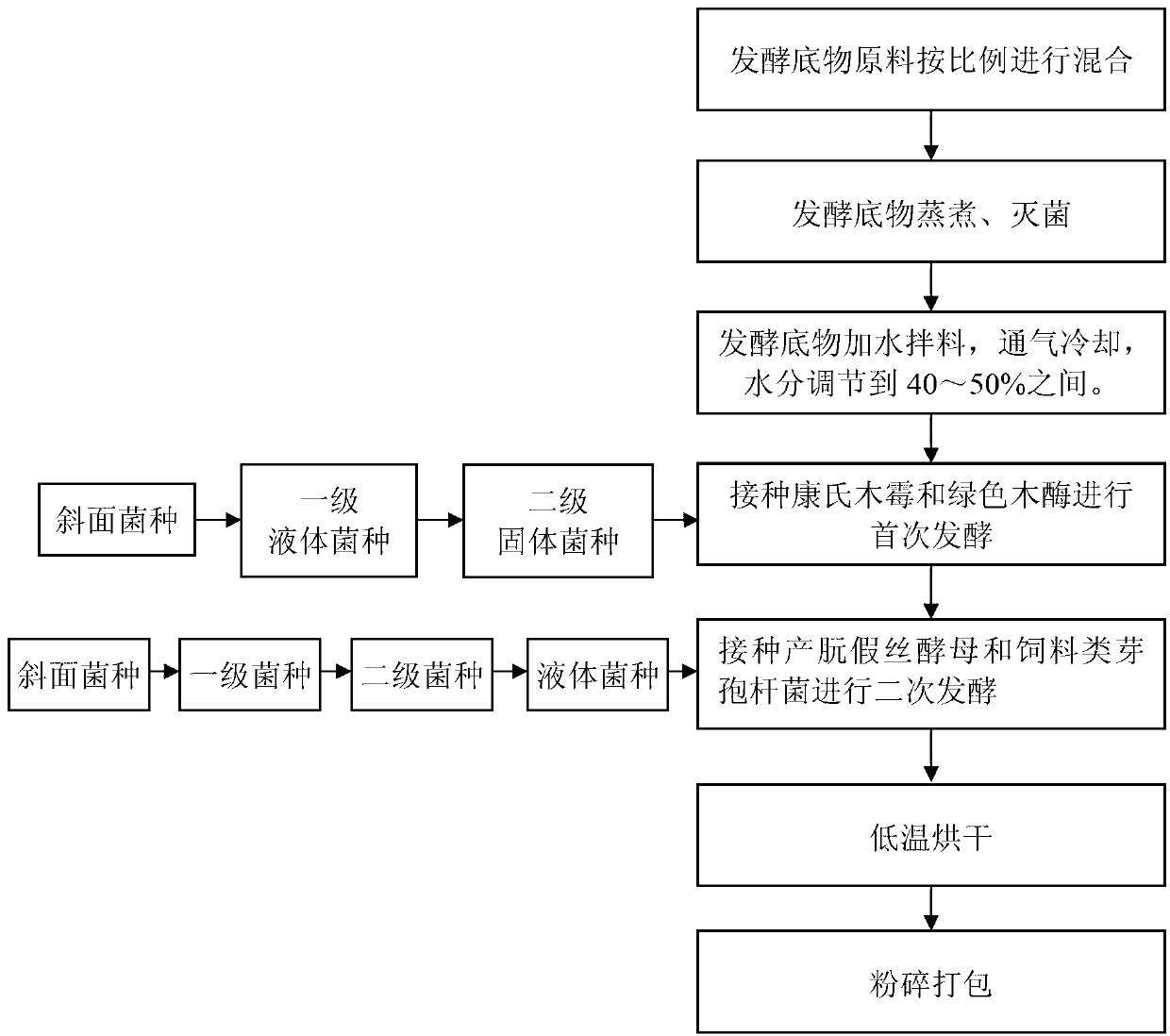

[0056] see figure 1 , prepare the novel feed for ruminants of the present embodiment according to the following method:

[0057] 1. Accurately weigh 100kg of rice husk bran, 100kg of sunflower husk powder, 100kg of corn husk, 100kg of bran, 100kg of distiller's grains, 80kg of potato residue, 50kg of apple residue, 100kg of tomato residue, 100kg of corn straw powder, 100kg of corn glycoprotein, and okara 50kg and 20kg of urea, mixed evenly to make the fermentation substrate.

[0058] 2. After the fermentation substrate is mixed in proportion, 0.3 MPa saturated steam is introduced into the tempering mixer, and cooking and sterilization are carried out at 145°C for 5 minutes. During the cooking process, the mixer is kept in normal operation.

[0059] After the sterilization is completed, spray water, ventilate, and cool the tempering mixer. The ratio of fermentation substrate to water addition is 1:0.1. The temperature of the material is reduced to 30°C, and the water content i...

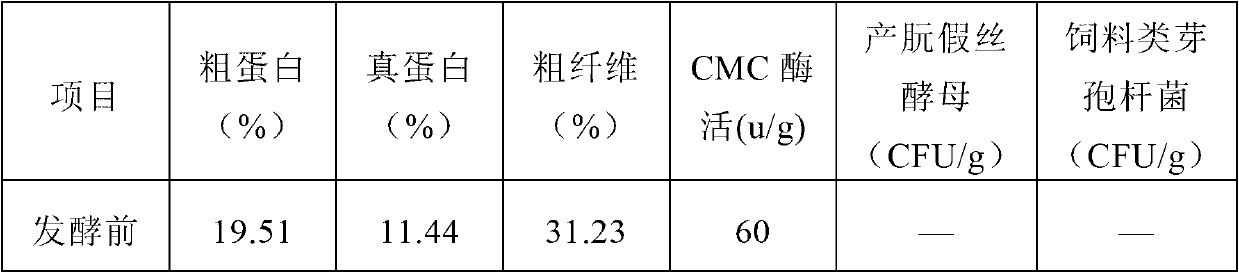

Embodiment 2

[0092] see figure 1 , prepare the novel feed for ruminants of the present embodiment according to the following method:

[0093] 1. Accurately weigh 110kg of rice husk bran, 110kg of sunflower husk powder, 110kg of corn husk, 110kg of bran, 110kg of distiller's grains, 80kg of potato residue, 20kg of apple residue, 80kg of tomato residue, 100kg of corn straw powder, 100kg of corn glycoprotein, and okara 50kg and 20kg of urea, mixed evenly to make the fermentation substrate.

[0094] 2. After the fermentation substrate is mixed in proportion, 0.3 MPa saturated steam is introduced into the tempering mixer, and cooking and sterilization are carried out at 145°C for 5 minutes. During the cooking process, the mixer is kept in normal operation.

[0095] After the sterilization is completed, spray water, ventilate, and cool the tempering mixer. The ratio of fermentation substrate to water addition is 1:0.1. The temperature of the material is reduced to 30°C, and the water content is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com