Micro-fluidic chip for high-flux automatically rationing and mixing and use method and application of chip

A microfluidic chip, quantitative distribution technology, applied in chemical instruments and methods, measuring devices, analytical materials, etc., can solve the problems of complex interfaces, high power consumption, poor portability, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

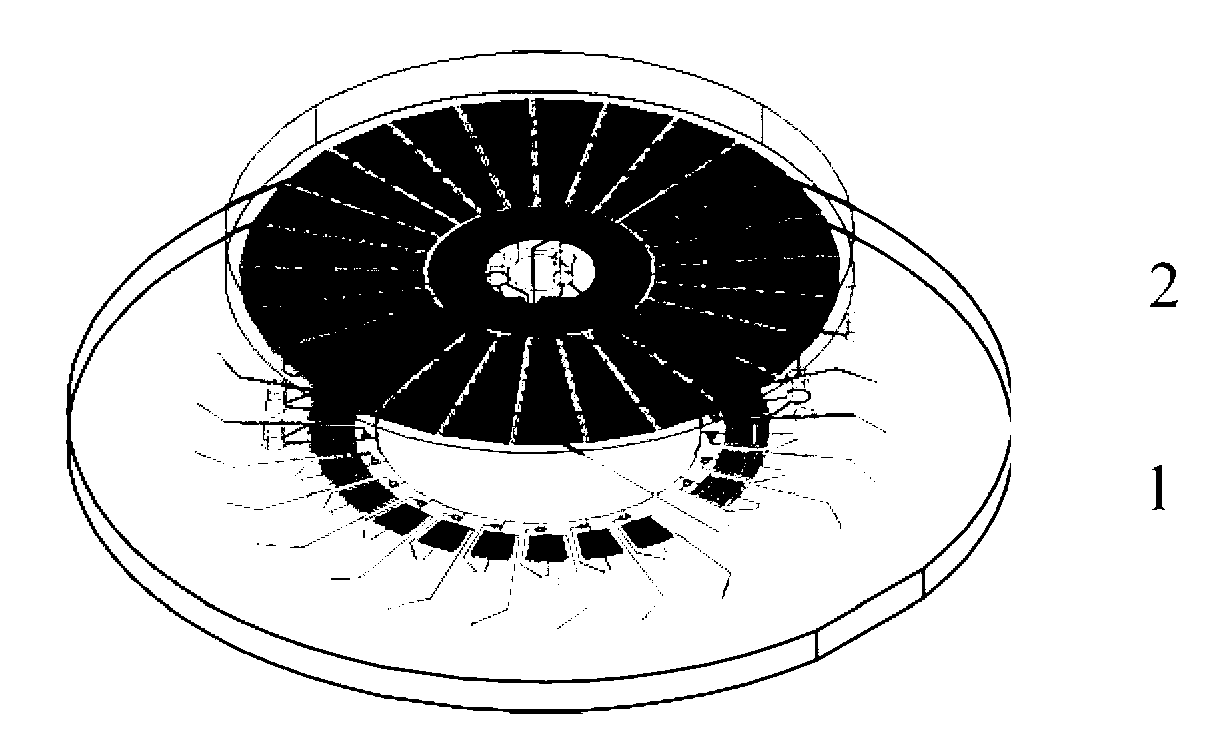

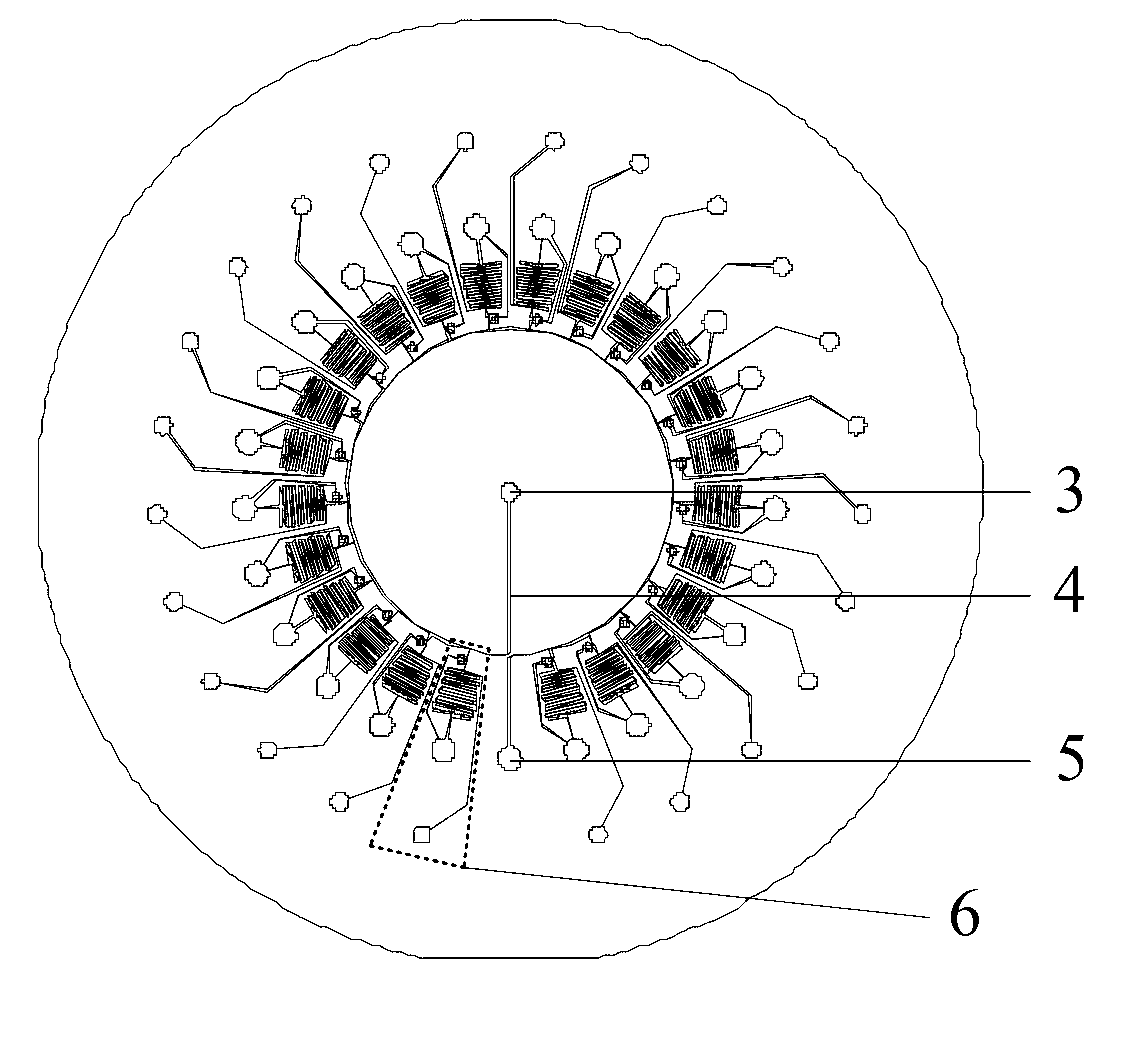

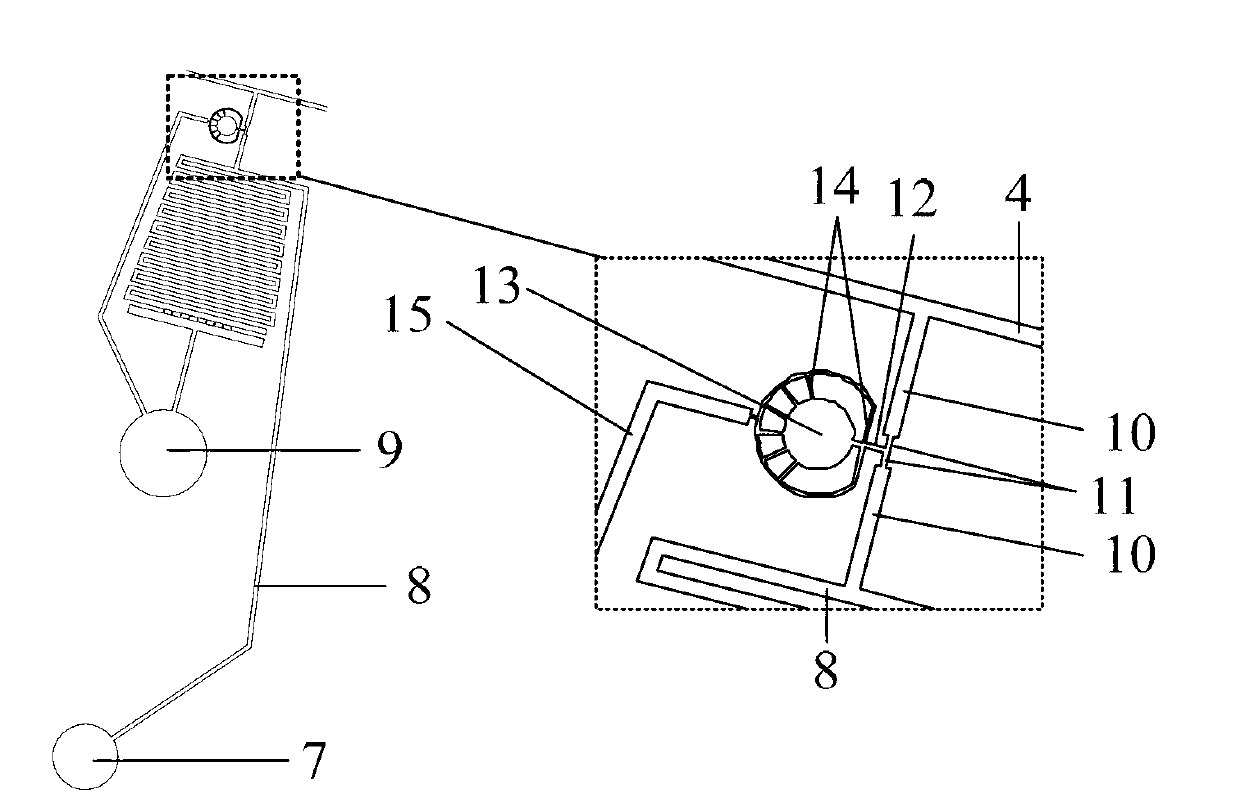

[0016] like figure 1As shown, the microfluidic chip of the present invention is a combined microfluidic chip, which consists of a chip body (1) integrated with a micropipe network and with hydrophobic properties on the pipe surface, and another chip body (1) integrated with multiple microcavities and microcavities The PDMS pump body (2) containing the micropillar array is assembled and constituted; the chip body (such as figure 2 shown) contains a main injection port (3), a main injection micropipe (4), a main vent / waste pool (5) and multiple branch structural units (6); each branch structural unit ( 6) (if image 3 shown) includes a branch inlet (7), a branch sample injection micropipe (8), a branch vent (9), two constant-volume micropipes (10), two primary connection micropipes (11 ), a mixing micropipe (12), a microreaction chamber (13), a group of secondary connection micropipes (14) and a ventilation micropipe (15); among them, the transverse The cross-section is smal...

Embodiment 2

[0019] The microfluidic chip prepared in Example 1 was applied to the high-throughput screening of protein crystallization conditions, and the method was as follows: firstly, the pre-degassed PDMS pump body (2) was aligned and assembled with the chip main structure (1), and then Immediately add various crystallization agents with different proportions and concentrations to each branch inlet (7), drop the protein solution to be crystallized into the main inlet (3), and absorb the negative gas formed by the air in the pipeline through the pump body (2). The synergistic effect of the pressure driving force and the design of the capillary microvalve in the micropipeline network distributes the protein solution and the crystallization agent into each microreaction chamber (13) for mixing, and then removes the PDMS pump body (2) and conducts the micro-reaction in each branch. Silicone oil is added to the sample hole (7), and the silicone oil will quickly fill the microchannel network...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com