Method for relieving acidic suppression of methanogenic phase during anaerobic digestion of organic wastewater

An anaerobic digestion and organic wastewater technology, applied in anaerobic digestion treatment, waste fuel, etc., can solve the problems of slow growth of methanogens, loss of methanogens, poor settling properties, etc., and achieve reduction of anaerobic active pollution Effects of mud loss, slowing acidic inhibition of methanogenic phase, and increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

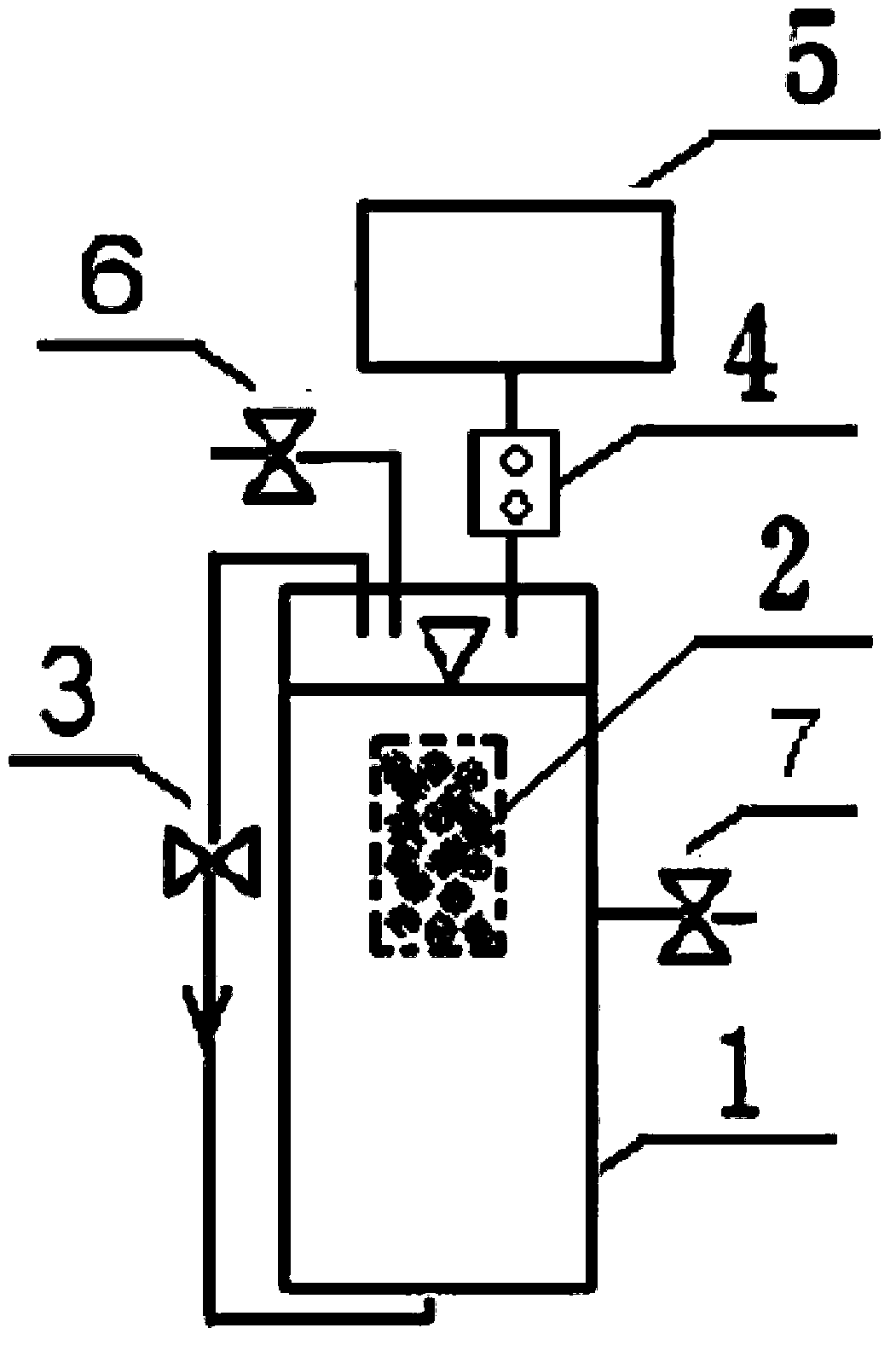

[0027] Such as figure 1 As shown, the device mainly includes: anaerobic digestion reactor 1, ion exchange resin bag 2, anaerobic aeration unit 3, anaerobic digestion gas phase pressure adjustment switch 4, anaerobic gas buffer unit 5, water inlet 6 and outlet 7 .

[0028] The gas phase pressure in the anaerobic digestion reactor 1 is controlled between 0.102-0.11MPa; when the pressure exceeds 0.11Mpa, the anaerobic digestion gas phase pressure adjustment switch 4 actively exhausts into the anaerobic gas buffer unit 5; the anaerobic digestion reactor 1 When the gas phase pressure is lower than 0.102Mpa during drainage, anaerobic gas is actively transferred from the anaerobic gas buffer unit 5 to the anaerobic digestion reactor 1 through the anaerobic digestion gas phase pressure regulating switch 4 .

[0029] Specific processing methods:

[0030] TiO 2 Improve the settling characteristics of anaerobic activated sludge.

[0031] Both anaerobic reactors A and B are composed o...

Embodiment 2

[0036] The difference from Example 1 is that the simulated organic wastewater added to reactors A and B is a diluted glucose solution with a final BOD concentration of 1280 mg / L, and other operating conditions remain unchanged. Three cycles were run in this way, the average time for reactor A was 12.8 hours, and the average time for reactor B was 24.7 hours. After adding 4% anion exchange resin, the anaerobic digestion cycle was shortened by 47.4%.

Embodiment 3

[0038] The difference from Example 1 is that the simulated organic waste water added in reactors A and B is diluted acetic acid solution with a final BOD concentration of 1920 mg / L, and other operating conditions remain unchanged. Running three cycles in this way, the average time for reactor A is 43.9 hours, and the average time for reactor B is 53.1 hours. After adding 4% anion exchange resin, the anaerobic digestion cycle is shortened by 17.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com