Chlorine salt corrosion resistant system with chemical microcapsule for underground structure concrete

An underground structure and microcapsule technology, which is applied in the field of concrete engineering, can solve the problems of inability to effectively control the diffusion of chloride salts for a long time, the construction of anti-corrosion coatings is difficult, and the diffusion of chloride salts cannot be prevented, and the anti-chloride salt corrosion ability is effective for a long time. , the effect of improving safety and durability, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

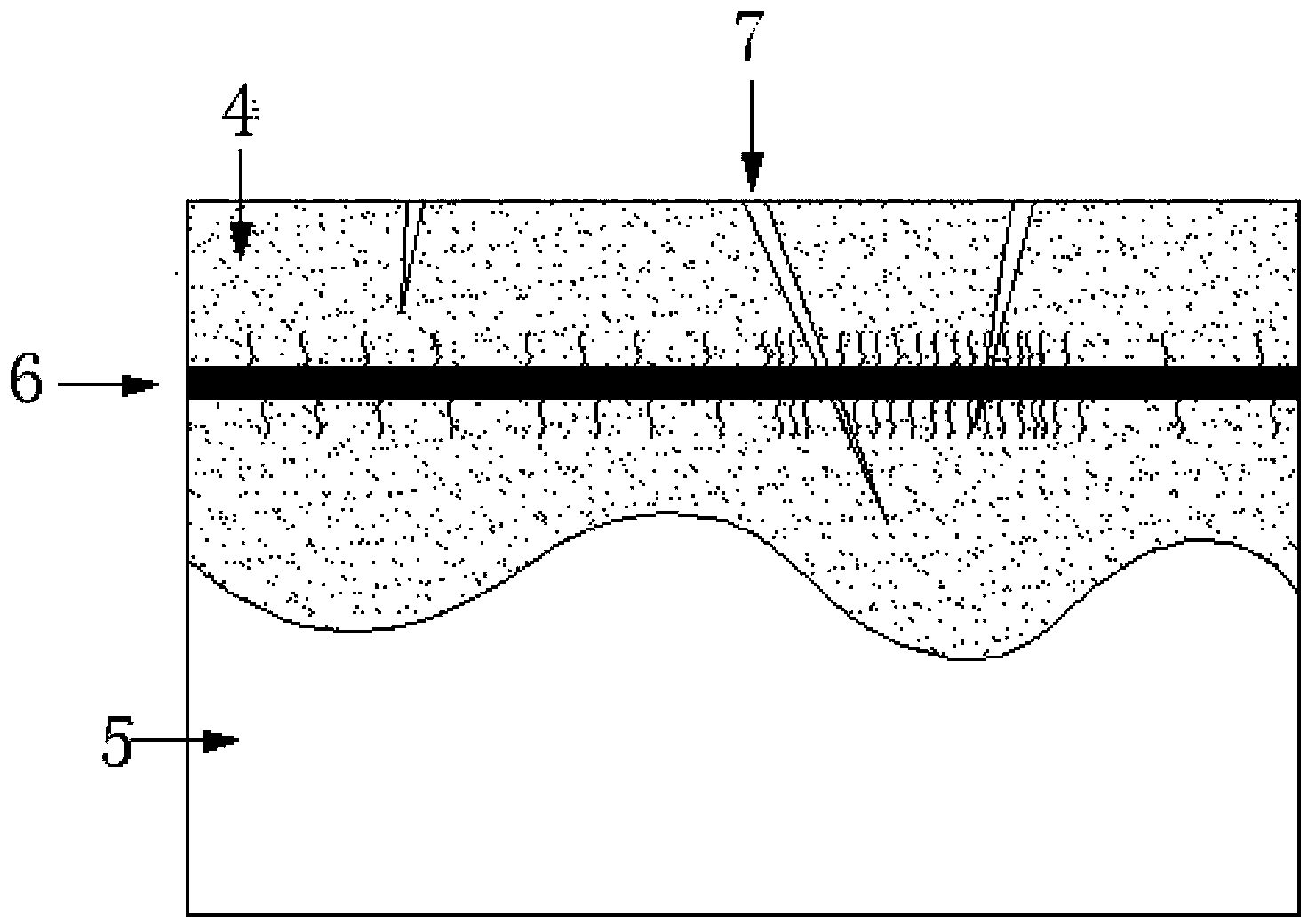

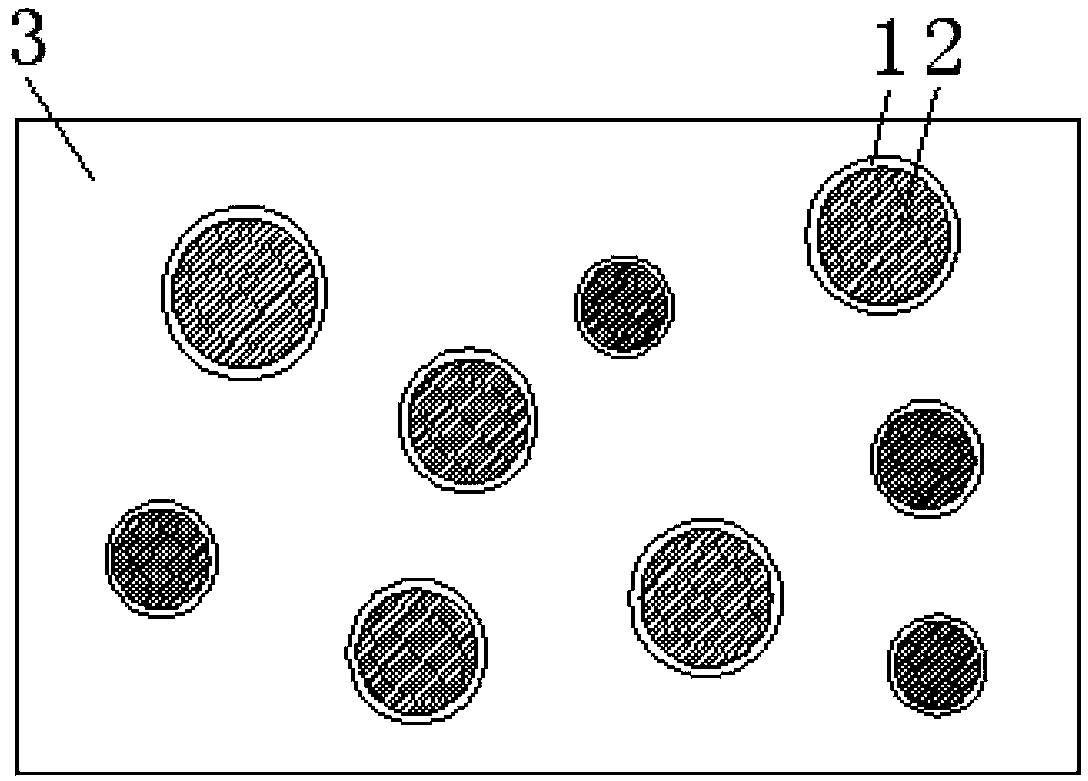

Method used

Image

Examples

Embodiment 1

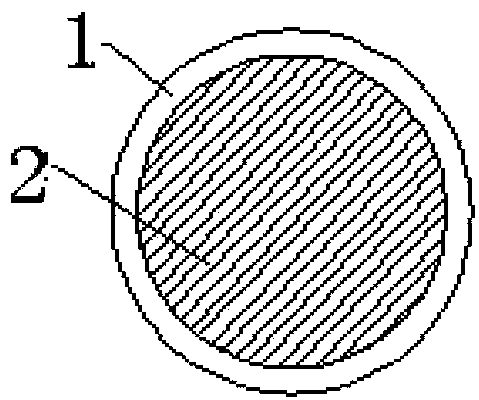

[0058] Preparation of chemical microcapsules: AgNO with a concentration of 219g / 100mL 3 aqueous solution, the AgNO 3 The aqueous solution is wrapped in chemical microcapsules made of polyurea formaldehyde.

[0059] Prepare chemical microcapsules by traditional in-situ polymerization method: Weigh 50 grams of urea and 90 grams of formaldehyde to make a mixed solution, adjust the pH to 8-9 with dilute NaOH solution, and then conduct a heating reaction in a water bath for a period of time until it is completely dissolved to obtain prepolymerization body. Emulsify the silver nitrate solution in SDBS (sodium dodecylbenzenesulfonate) solution for a period of time, then add it to the prepolymer solution and adjust the pH to 2-2.5 with a dilute acid solution, and at the same time raise the temperature to 55°C and stir the reaction 2 Hours, then raise the temperature to 65°C for reaction, then wash with acetone and distilled water, filter with suction, and dry to obtain chemical micr...

Embodiment 2

[0064] With reference to the method in embodiment 1, respectively to AgF aqueous solution, Hg 2 (NO3) 2 Aqueous solution, Pb(NO 3 ) 2 Aqueous solution, TiNO 3 The aqueous solution was tested, and the specific experimental conditions are shown in Table 1. Each microcapsule is prepared by traditional in-situ polymerization method.

[0065] Table 1

[0066]

AgF aqueous solution

Pb(NO 3 ) 2 aqueous solution

Hg 2 (NO3) 2 aqueous solution

TiNO 3 aqueous solution

configuration concentration

180g / 100mL

56g / 100mL

6g / 100mL

5g / 100mL

chemical microencapsulation material

Urea-formaldehyde resin

polyurethane rubber

Chemical microcapsule diameter

100μm

950μm

300μm

200μm

Chemical Microcapsule Wall Thickness

0.3μm

5μm

1μm

3μm

volume of microcapsules

5%

15%

5%

5%

[0067] The resulting AgF aqueous solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com