Conjugated polyelectrolyte photoelectric material containing amphoteric side chains and application thereof in organic light-emitting diode

A technology of conjugated polyelectrolyte and photoelectric materials, applied in organic chemistry, circuits, electrical components, etc., can solve the problems of low electrical conductivity, reduced lifetime and stability of organic light-emitting diode devices, and poor PVK hole injection/transport performance. Good and other problems, to achieve high conductivity, to avoid the effect of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of 4,4-dibromo-2-nitrobiphenyl (1)

[0025] Dissolve 4,4-dibromobiphenyl (20g, 64mmol) in glacial acetic acid (300mL), heat and stir at 110°C, add concentrated nitric acid (70%, 132mL) dropwise to glacial acetic acid, heat for 6h until solid Slowly dissolve, then cool to room temperature. The reaction solution was filtered, the solid was washed with water, and then recrystallized with ethanol to obtain a yellow solid (17.6g, yield77%). 1 H-NMR (300MHz, CDCl 3 ): (ppm) 8.32 (d, 2H), 8.29 (d, 2H), 7.77 (dd, 2H).

Embodiment 2

[0027] Preparation of 2,7-dibromocarbazole (2)

[0028] Triethyl phosphate (60 mL) added with compound 1 (16.5 g, 46.1 mmol) was heated to reflux for 18 h under nitrogen protection. The reaction liquid was distilled off under reduced pressure to remove excess solvent, and the residue was dissolved in a small amount of dichloromethane, then precipitated with petroleum ether to obtain the initial product, and then silica gel / petroleum ether column chromatography was used to obtain a white solid (9.28g, yield 62%). 1 H-NMR (300MHz, CDCl 3 ): δ (ppm) 8.20 (br, 1H, NH); 7.92 (d, 2H); 7.56 (d, 2H); 7.35 (dd, 2H).

Embodiment 3

[0030] Preparation of p-methylphenyl-1-bromo-6-hexyl ether (3)

[0031] Add p-cresol (28g), 1,6-dibromohexane (220mL), potassium carbonate (60g), tetrabutylammonium bromide (3.8g) and acetone (150mL) into a 500mL flask, heat and stir to reflux 48h. The reaction was cooled to room temperature, filtered, and the filtrate was spun with a circulating water pump until the mass was no longer reduced, and then distilled under reduced pressure with an oil pump, and the fraction collected at 210°C~220°C was a colorless oily product (53.5g, yield76.1%). 1 H-NMR (300MHz, CDCl 3 ): δ(ppm)7.10(d,2H); 6.82(d,2H); 3.96(t,2H); 3.45(t,2H); 2.32(s,3H); 1.8(br,8H).

PUM

| Property | Measurement | Unit |

|---|---|---|

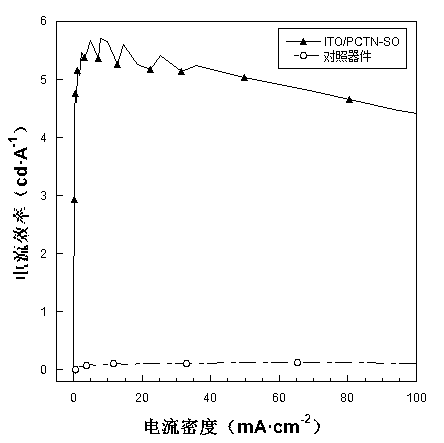

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com