Novel heat-resistant rubber part

A technology of heat-resistant rubber and parts, which is applied in the direction of building components, building insulation materials, construction, etc., can solve the problems of poor heat-resistant aging performance, breaking strength and elongation at break of rubber, etc., to improve heat aging performance, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The specific production steps are as follows:

[0024] Rubber production:

[0025] ⑴ Weigh various ingredients according to the specific formula ratio; according to the components, 100 parts of 1# natural rubber, 2 parts of TT accelerator (Chinese name: tetramethylthiuram disulfide, molecular formula: C6H12N2S4), 4 parts of zinc oxide, 4010 anti-aging agent (Chinese name: N-phenyl-N'-cyclohexyl-p-phenylenediamine, molecular formula: C15H18N2) 1 part, 1 part stearic acid, 7 parts pitch, 15 parts spray carbon black, 50 parts calcium carbonate, Anti-aging agent BLE (Chinese name: high temperature condensation product of acetone and diphenylamine 4-aminobiphenyl, molecular formula: C15H15N) 2.7 parts, barium sulfate 31 parts, o-dibutyl ester 3 parts. The weight unit of each part in the component is determined according to production needs, such as one kilogram per part.

[0026] (2) Take 100 parts of 1# natural rubber and add it to the rubber mixing machine. After mixi...

Embodiment 2

[0034] The production process of embodiment 2 is identical with embodiment 1, and difference is that the ratio of rubber material components is different, and the rubber material composition of embodiment 2 is calculated as follows by component: 1# natural rubber 110 parts, accelerator TT (Chinese name: Tetramethylthiuram disulfide, molecular formula: C6H12N2S4) 3 parts, zinc oxide 5 parts, antioxidant 4010 (Chinese name: N-phenyl-N'-cyclohexyl-p-phenylenediamine, molecular formula: C15H18N2) 1.5 parts, 2 parts of stearic acid, 8 parts of asphalt, 20 parts of spray carbon black, 55 parts of calcium carbonate, 2.7 parts of anti-aging agent BLE (Chinese name: high-temperature condensation product of acetone and diphenylamine 4-aminobiphenyl, molecular formula: C15H15N), barium sulfate 31 parts, 4 parts of o-dibutyl ester.

Embodiment 3

[0035] The production process of embodiment 3 is identical with embodiment 1, and difference is that rubber material component ratio is different, and the rubber material composition of embodiment 3 is calculated as follows by component: 1# natural rubber 120 parts, accelerator TT (Chinese name: Tetramethylthiuram disulfide, molecular formula: C6H12N2S4) 4 parts, zinc oxide 6 parts, antioxidant 4010 (Chinese name: N-phenyl-N'-cyclohexyl-p-phenylenediamine, molecular formula: C15H18N2) 2 parts, 3 parts of stearic acid, 9 parts of asphalt, 25 parts of spray carbon black, 60 parts of calcium carbonate, 2.7 parts of anti-aging agent BLE (Chinese name: high temperature condensation product of acetone and diphenylamine 4-aminobiphenyl, molecular formula: C15H15N), barium sulfate 31 parts, 5 parts of o-dibutyl ester.

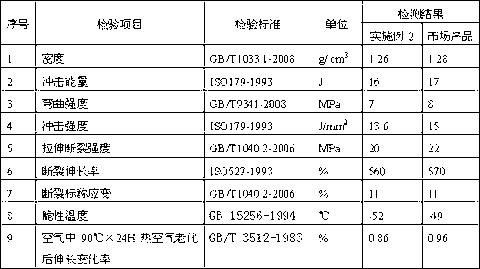

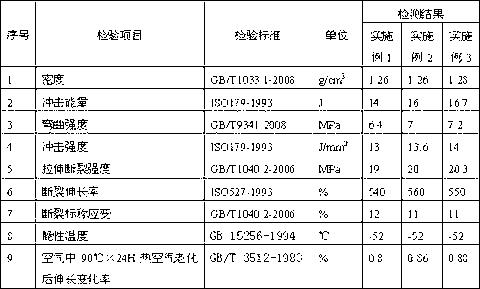

[0036] Performance comparison of three kinds of embodiments

[0037]

[0038] The current market product comparison of embodiment 2 formula and known technology

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com