Coal pyrolysis furnace

A coal pyrolysis and furnace shell technology, applied in the field of coke ovens, can solve problems such as the inability to eliminate environmental pollution, large footprint of CDQ coke towers, and overcapacity of coke, so as to avoid pollution waste and energy loss, and improve oil and gas production capacity. Output, the effect of increasing oil and gas output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation

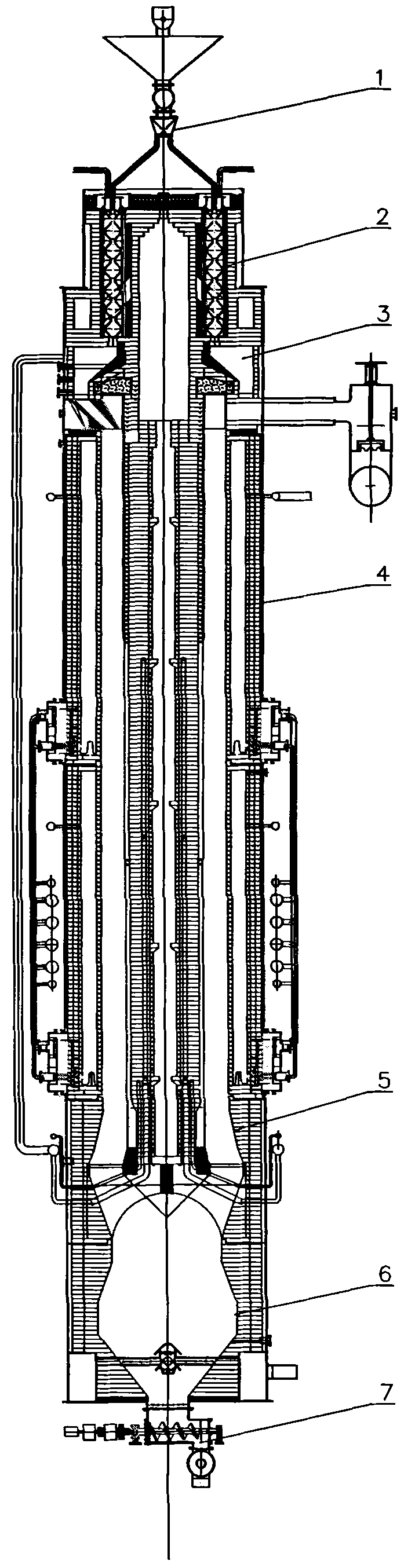

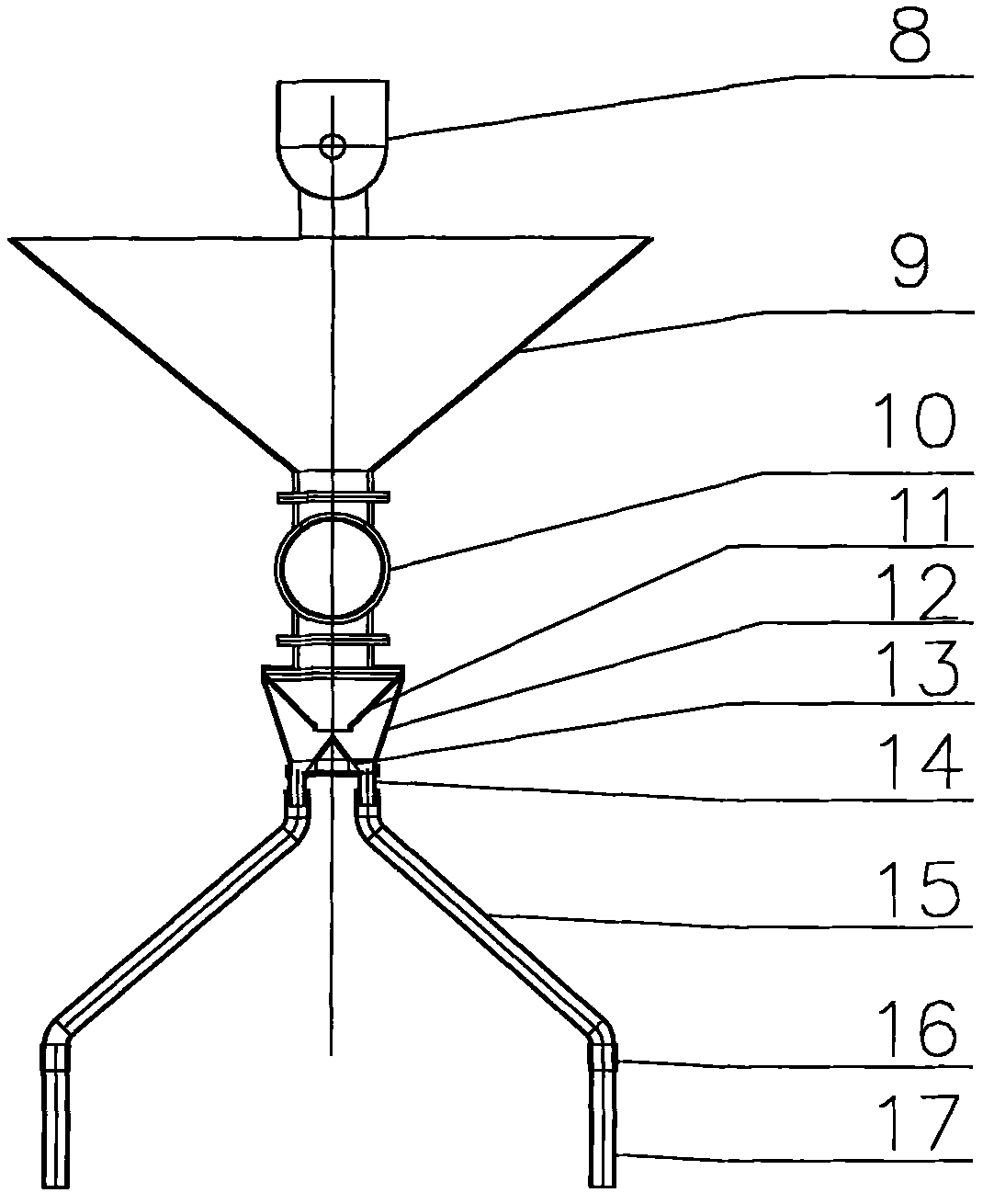

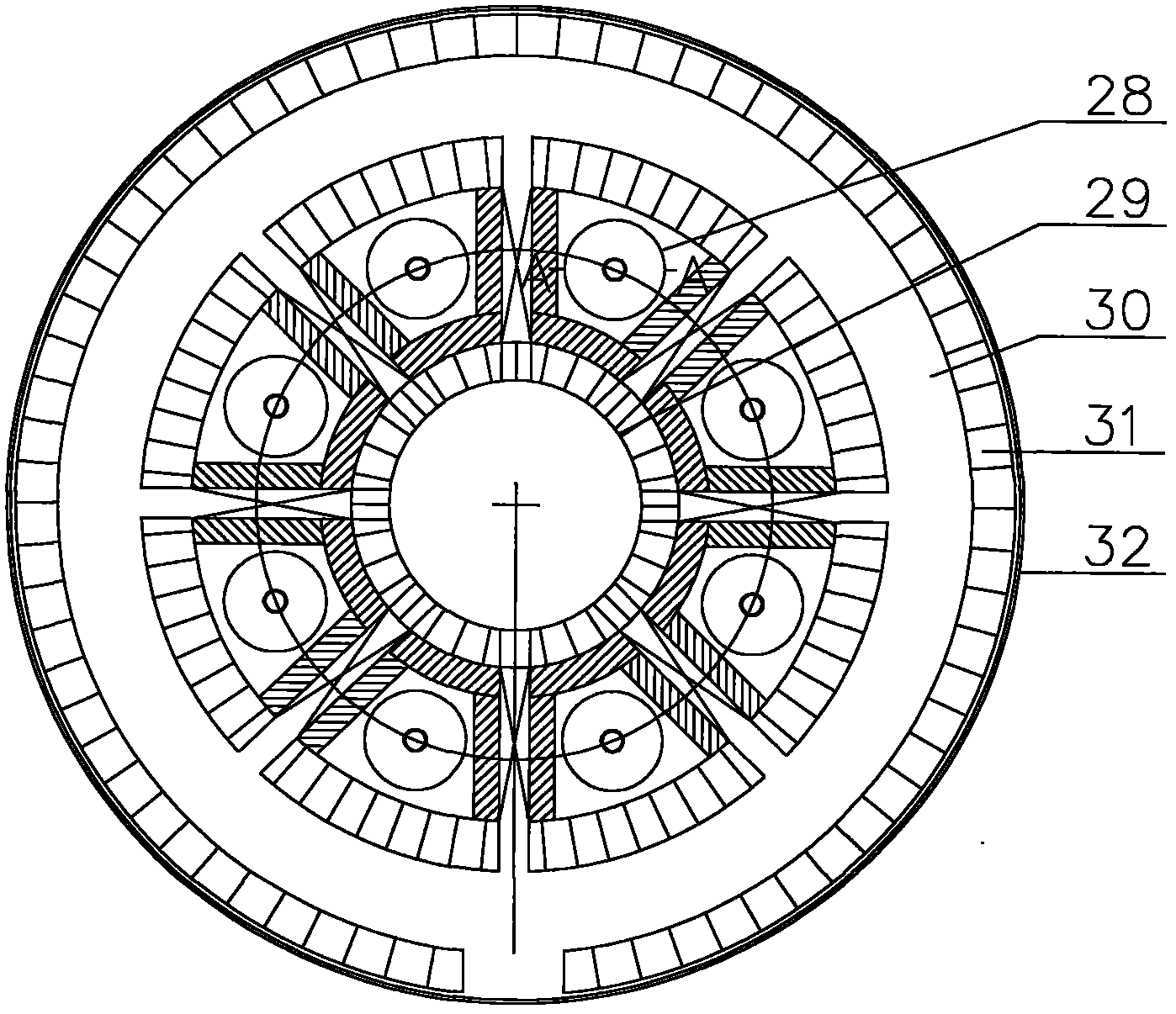

[0020]A coal pyrolysis furnace, comprising: a coal feeding device 1 for the coal pyrolysis furnace, a coal preheating device 2 for the coal pyrolysis furnace, a preheating coal feeding device 3 for the coal pyrolysis furnace, and a coal pyrolysis furnace coal The heating device 4 of the coal pyrolysis furnace, the coke reforming device 5 of the coal pyrolysis furnace, the CDQ device 6 of the coal pyrolysis furnace, and the coke pushing device 7 of the coal pyrolysis furnace; the coal feeding device 1 of the coal pyrolysis furnace includes a spiral Coal feeder 8, hopper 9, rotary coal feeder 10, funnel plate 11, coal distributor 12, equalizer 13, casing 14, feeding pipe 15, movable casing 16 and straight pipe 17; spiral coal feeder 8 is provided with a hopper 9, the hopper 9 is connected to the rotary coal feeder 10 through the flange, the rotary coal feeder 10 is connected to the coal distributor 12, and the coal distributor 12 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com