Radio frequency identification electronic tag and preparation method thereof

A radio frequency, electronic label technology, applied in the direction of digitally marked record carriers, record carriers used by machines, instruments, etc., can solve problems such as loss, and achieve the effect of improving conduction rate, reducing product cost, and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Using 80 grams of coated paper as the supporting layer material, use a coating machine to coat the functional polymer material on both sides of the supporting substrate with a coating thickness of 6 microns; the functional polymer material is made of water-based polyurethane resin material;

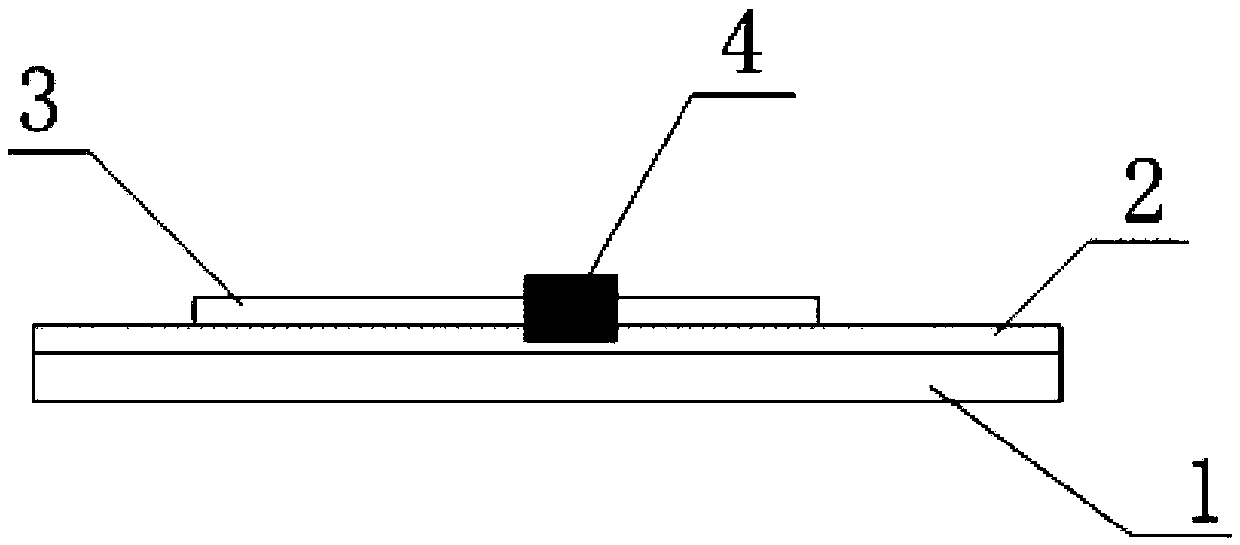

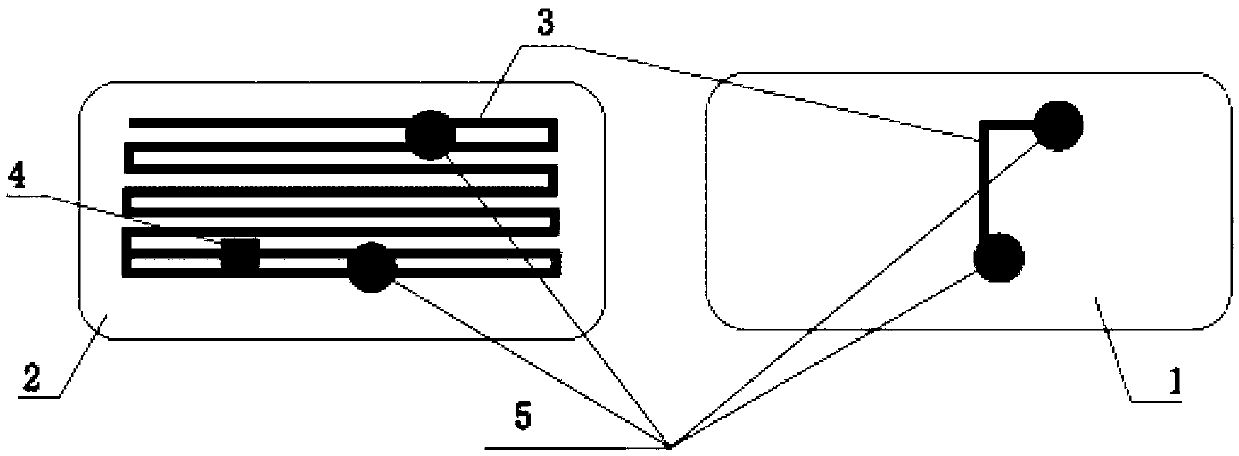

[0050] After drying through an infrared drying tunnel, use a 400-mesh screen-printed conductive silver paste on the surface of the functional polymer coating to form an RFID antenna after drying, and pass the RFID chip through a thermosetting conductive adhesive (XH9850 from NAMICS, Japan). ) for bonding and curing by hot pressing, the hot pressing temperature is 160°C, and the curing time is 8 seconds; use the RFID reader matching the chip to input data and obtain the product, its structure is as follows figure 1 shown.

Embodiment 2

[0052] With 40 grams of offset printing base paper as the supporting layer material, using a coating machine, the functional polymer material is coated on both sides of the supporting substrate, and the coating thickness is 8 microns; the functional polymer material is selected from a mixture of polyurethane resin and acrylic resin ( 2:1, weight ratio);

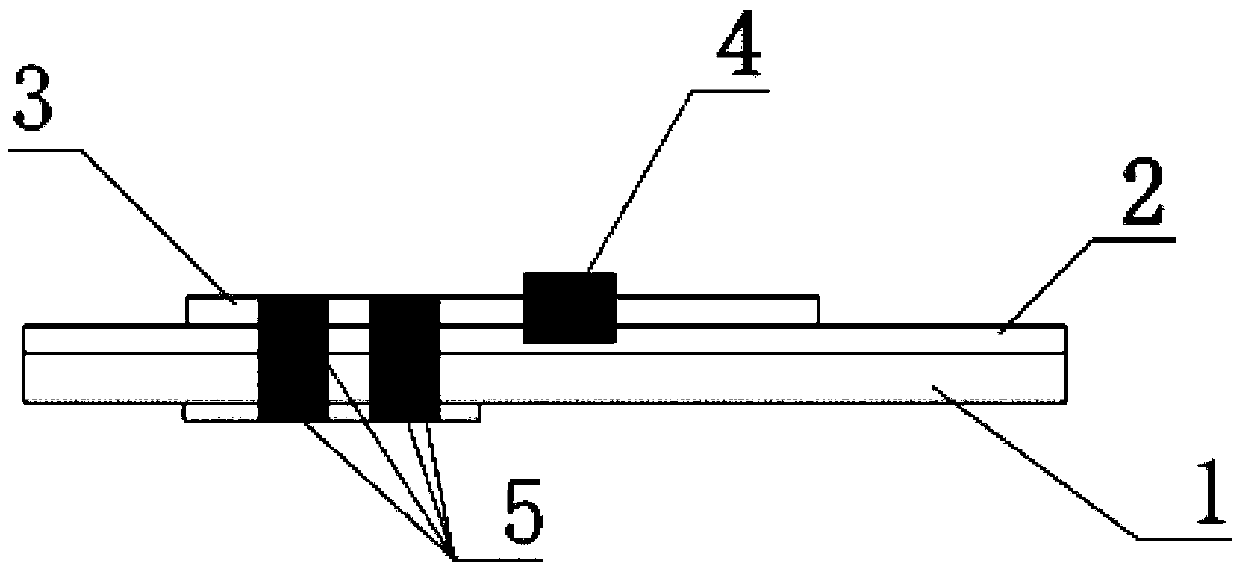

[0053] And dry through an infrared drying tunnel; compound the 16-micron thick aluminum foil with the above-mentioned functional polymer coating through an adhesive, and then print the antenna pattern on the aluminum foil by gravure printing, and then undergo acid or alkali etching and deinking treatment Finally, the etching antenna is formed; then the RFID chip is bonded with a thermosetting conductive adhesive, and cured by hot pressing. The hot pressing temperature is 160 ° C, and the curing time is 10 seconds; the RFID reader that matches the chip is used for data recording. Enter to get the product. Its structure is as ...

Embodiment 3

[0055] Using 80 grams of double-adhesive paper as the supporting layer material, use a coating machine to coat the functional polymer material on both sides of the supporting substrate with a coating thickness of 8 microns; the functional polymer material is made of water-based epoxy resin and acrylic resin. Mixture; (1:3, weight ratio);

[0056] Drying in an infrared drying tunnel; use 500-mesh screen-printed conductive silver paste as a seed layer on the functional polymer coating, and then deposit copper on the seed layer by chemical deposition to form an electroless copper-plated antenna; then The RFID chip is bonded with a thermosetting conductive adhesive (6998 from UNINWELL Company), and cured by hot pressing. The hot pressing temperature is 140°C, and the curing time is 10 seconds; use an RFID reader that matches the chip for data recording. Enter to get the product. Its structure is as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com