Multilayer composition containing fluoropolymer and method for fabricating the same, and solar cell module

A polymer layer and composition technology, applied in the direction of synthetic resin layered products, lamination, coating, etc., can solve the problems of yellowing of fluoropolymer layer and easy peeling of fluoropolymer layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

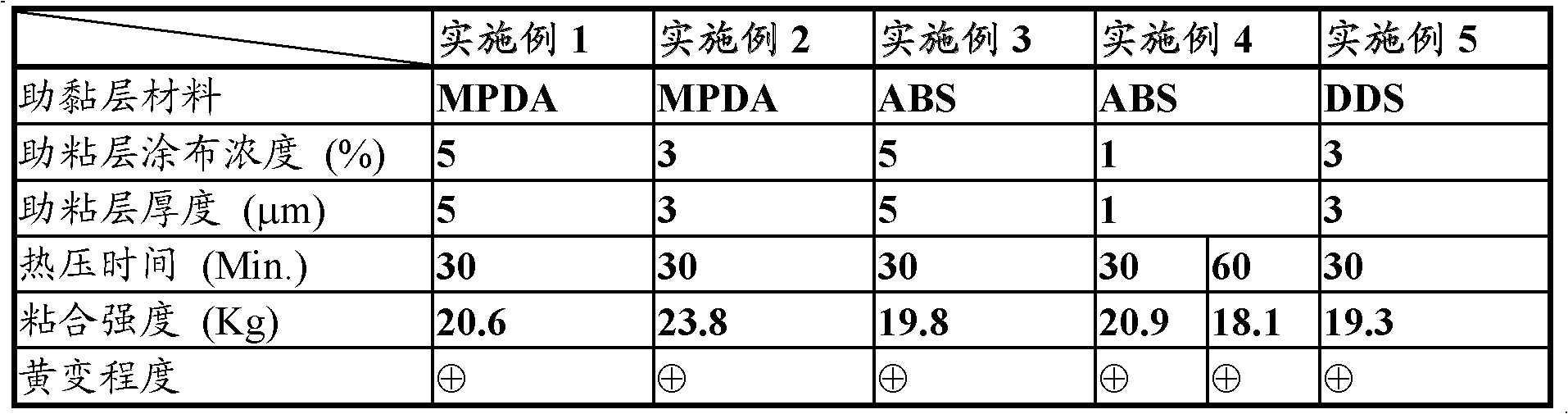

[0037] Please refer to Table 1, take the adhesion-promoting layer of Examples 1-5 in Table 1, dissolve the material of the adhesion-promoting layer in methanol, and prepare methanol solutions of various concentrations, and then apply the solution on a surface of 10cm×10cm with a scraper. On the fluoropolymer substrate (the production of the fluoropolymer substrate is to coat a layer of 20 μm fluorosilicone polymer / TiO on a 188 μm PET substrate 2 layer). (Represents fluorosiloxane polymer material mixed with 15wt% TiO 2 Inorganic materials, fluorosilicone polymers have a weight average molecular weight of about 10,000 g / mol).

[0038] Afterwards, place the substrate in an oven at 40°C for 30 minutes to remove the solvent, then place EVA (400-600 μm, model RC02B (product of Mitsui Chemicals)) on the above-mentioned substrate, and conduct a high-temperature process at 150°C and a pressure of 100Kpa. Pressing for 30 minutes or 1 hour, release the pressure after completion and wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com