Electrode for electric discharge machining

A technology for electrical discharge machining and electrodes, applied in the field of electrodes for electrical discharge machining, can solve problems such as a surge in electrode consumption, and achieve the effects of good surface accuracy, shortened machining time, reduced number of introductions and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0106] As raw materials for forming the W skeleton, 79 parts by mass of W with an average particle diameter of 4 μm, 1 part by mass of Ni with an average particle diameter of 1 μm, and 0.4 parts by mass of Sr with an average particle diameter of 7 μm were prepared.

[0107] As Sr boron oxide, SrCO mixed with an average particle size of 5 μm was used in a mass ratio of 2:1. 3 and B 2 o 3 , obtained by firing at 1050° C. for 30 minutes in an air atmosphere.

[0108] These powders were mixed by a Henschel mixer for 30 minutes to obtain mixed powders.

[0109] Next, the mixed powder was mold-pressed at a pressure of 50 MPa to obtain a rod-shaped compact.

[0110] In the heat-resistant container, a portion of the concave portion that fully accommodates the molded body is provided, and the molded body is placed therein. 2 Sintering was carried out at 1150° C. for 60 minutes in an atmosphere to obtain a skeleton.

[0111] A sufficient amount of plate-like Cu is provided on the s...

Embodiment 2)

[0145] Next, use a sample that changes the mass ratio of M1 and M2, or use boron oxides of one or more of iron group metals, alloys of M2 and iron group metals, Mg, Ca, Sr, Ba, and rare earth metals, Samples obtained from different types were selected, and the same test as sample 1 was performed.

[0146] The composition of each sample is shown in Table 6 and Table 7, and the evaluation is shown in Table 8 and Table 9.

[0147] Among them, regarding W, an iron group metal, and an alloy of an iron group metal, X-ray diffraction is performed on the sintered material, and the amount thereof is identified by the peak ratio.

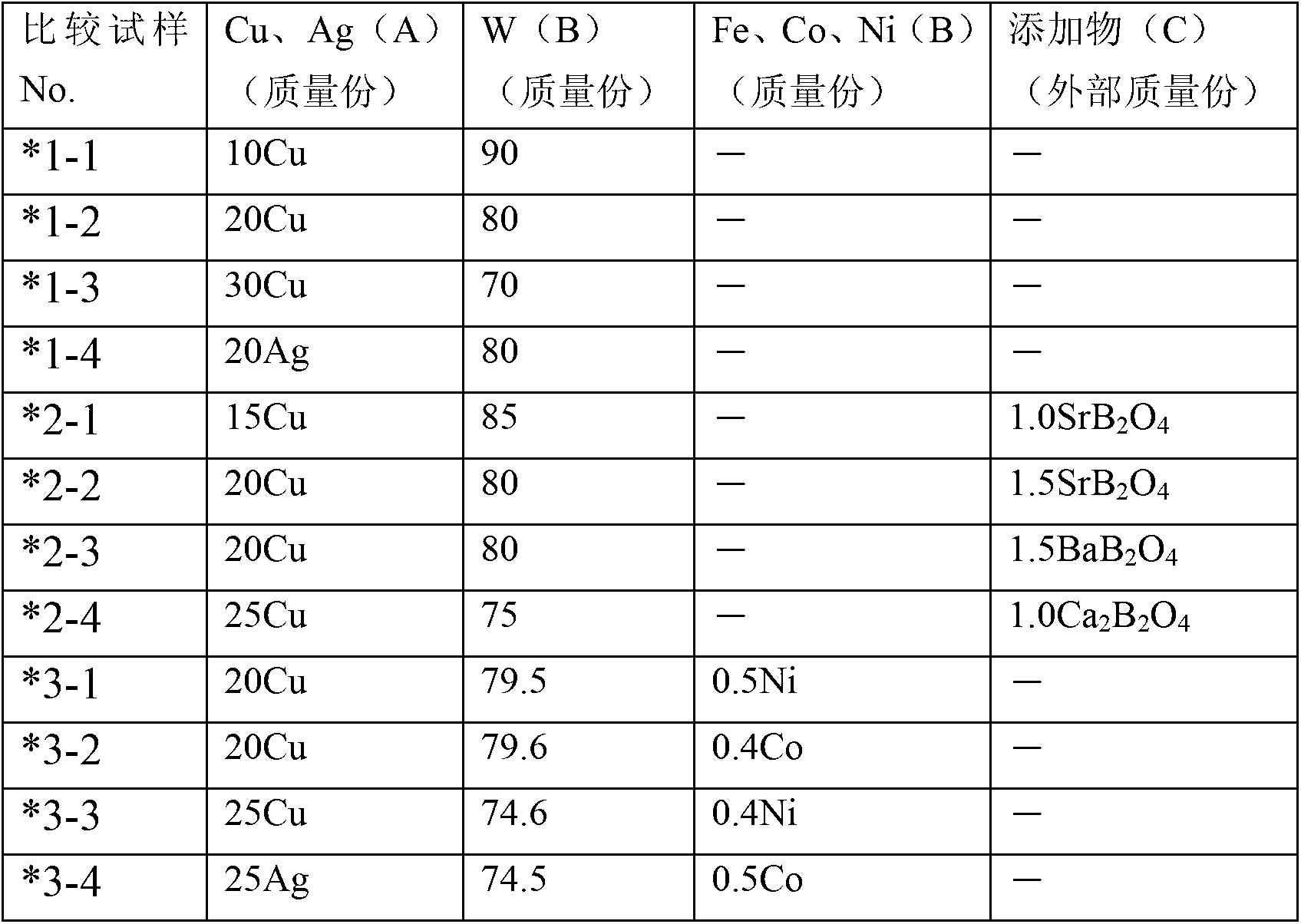

[0148] [Table 6]

[0149]

[0150] The samples marked with * in the table are comparative samples outside the scope of the present invention.

[0151] The samples marked with ** in the table are compositions containing 5 external mass % of Cr as *C.

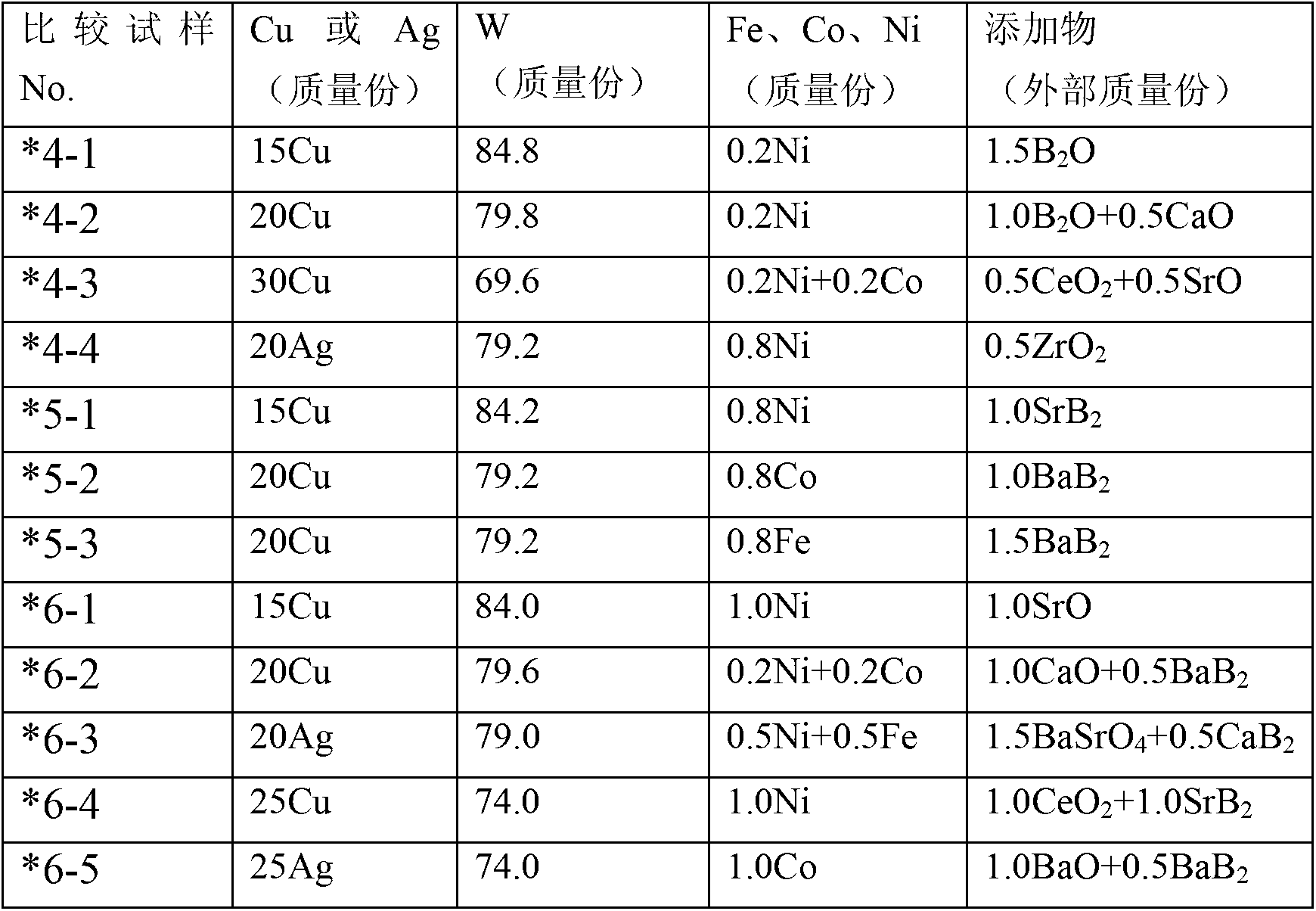

[0152] [Table 7]

[0153]

[0154] The samples marked with * in the table are comparative samples o...

Embodiment 3)

[0170] As starting materials, (A): 20 parts by mass of Cu, (B): 79.5 parts by mass of W and 0.5 parts by mass of Ni, (C): 0.5 parts by mass of external SrB 2 o 4 , the leaching atmosphere from H 2 Change the atmosphere to H 2 The conditions other than the mixed atmosphere with Ar were set in the same manner as in Sample 1, and samples were produced. This sample was subjected to the same test and evaluation as Sample 1. The results are shown below, and it was confirmed that it can be suitably utilized as an electrode for electric discharge machining.

[0171] Processing speed 90.0mm / sec, consumption rate 8.9%, surface roughness 15.0Ry (μm)

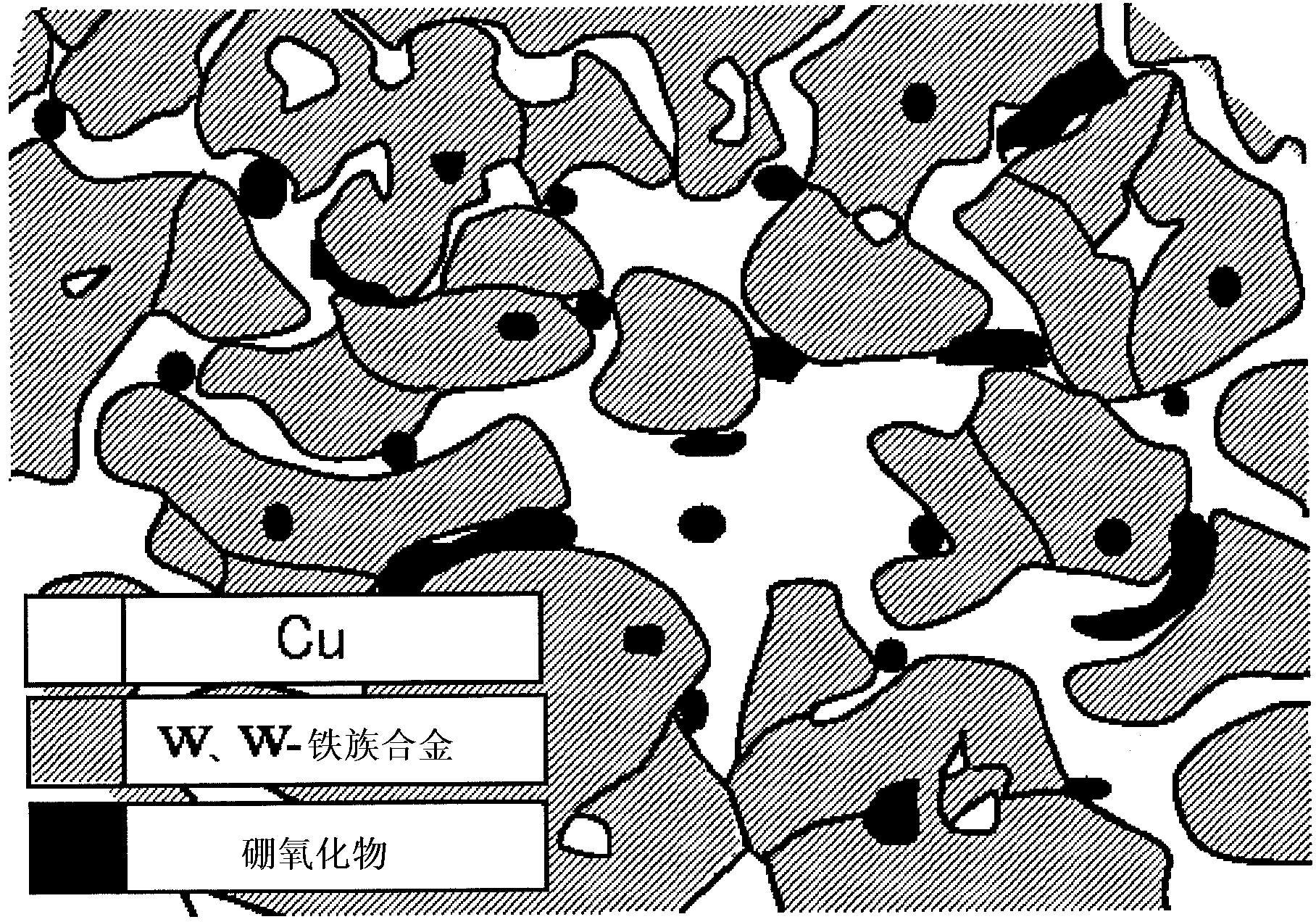

[0172] This sample was referred to as sample 200 . Sample 200 was observed using EPMA mapping and X-ray diffraction, and Cu, W, W-Ni alloy, Sr 2 B 2 o 5 In comparison, there are places where Sr, Ni, W, and O are observed in the same portion. Here, research by X-ray diffraction confirmed that Sr(Ni·W) 0.5 o 3 and B 2 O. The peak ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com