Method of pickling sauerkraut by using pure lactic acid bacteria under waterless and vacuum condition

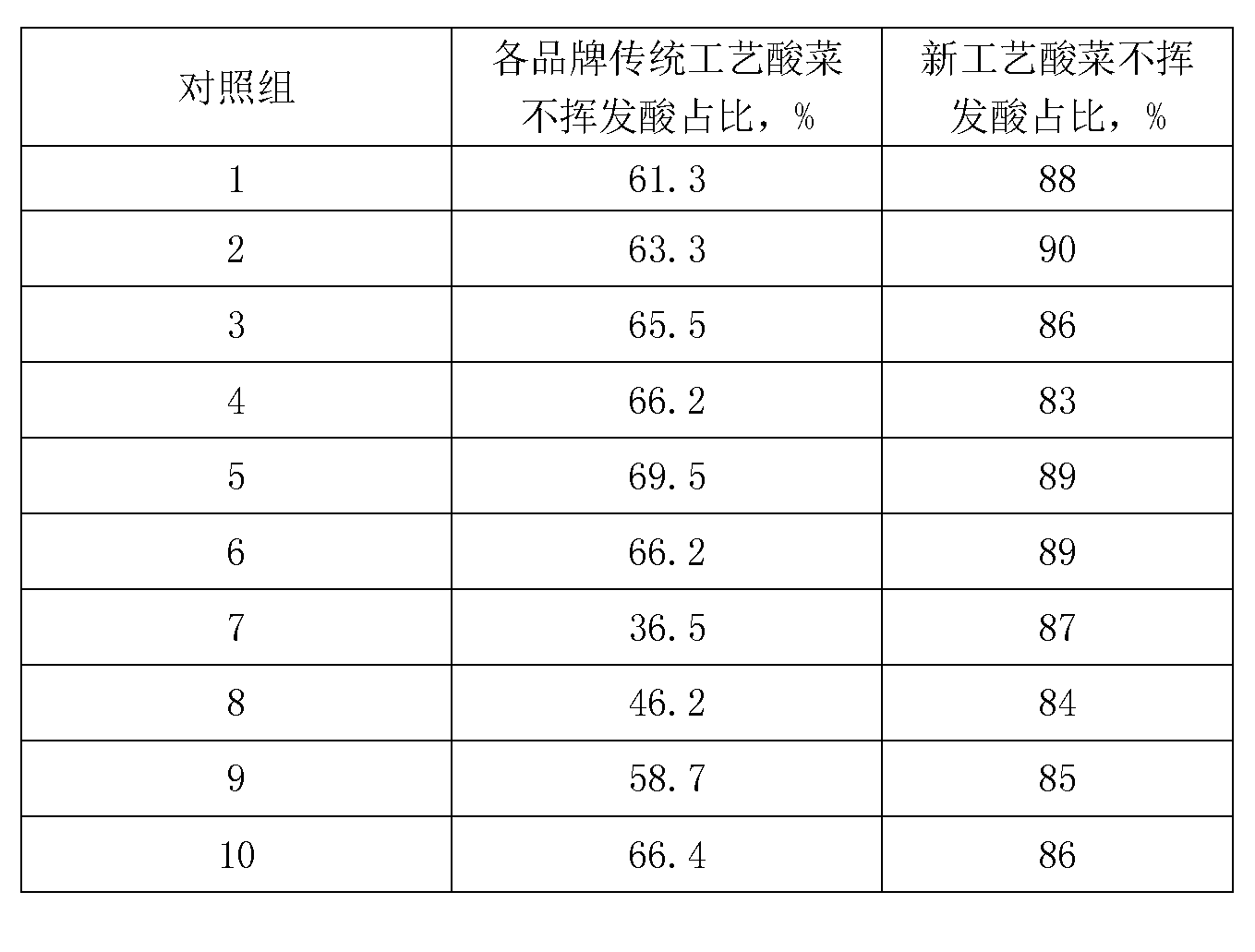

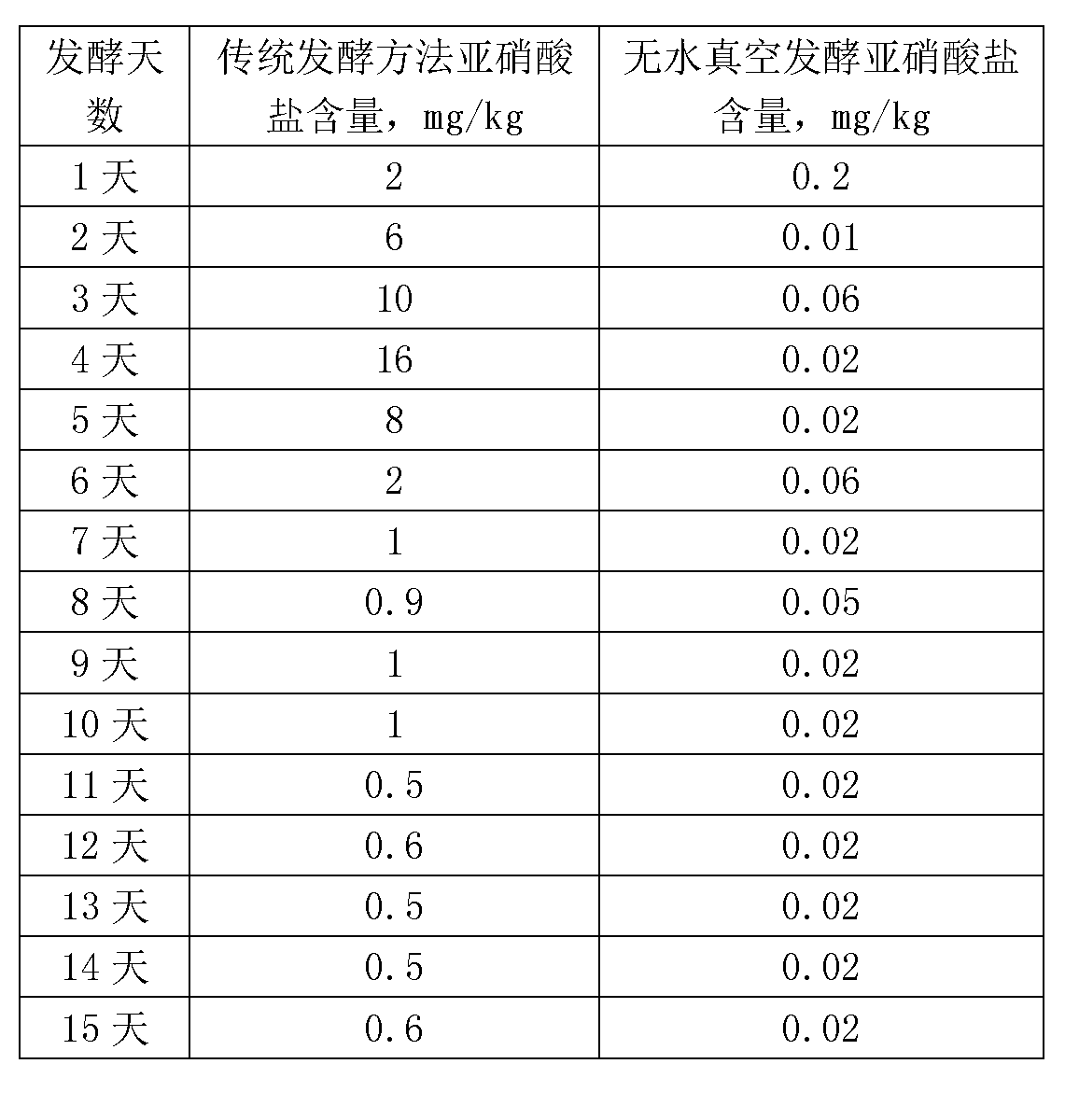

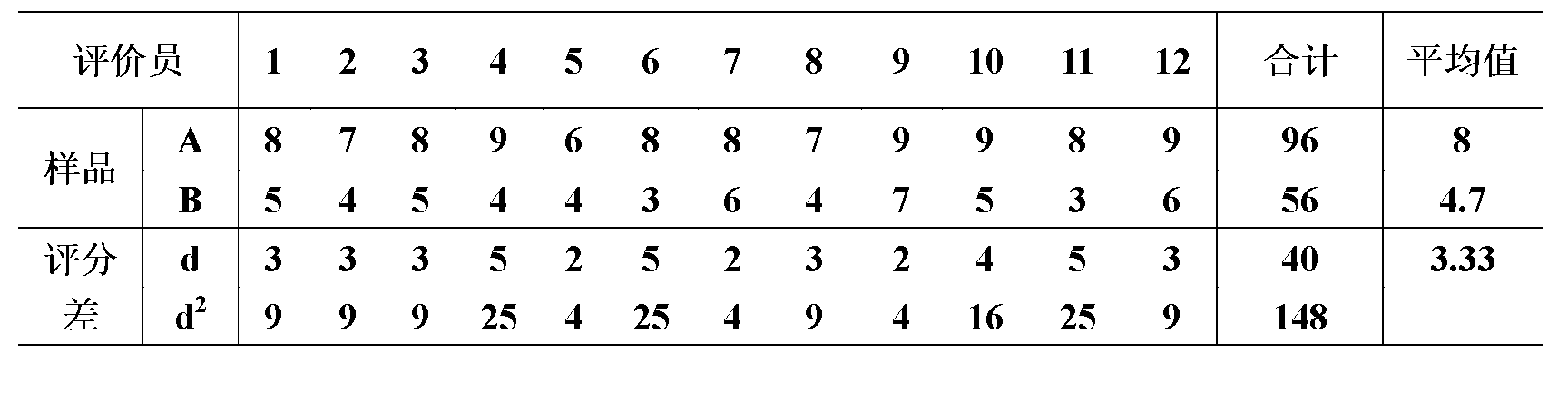

The technology of lactic acid bacteria and sauerkraut, which is applied in the field of food processing, can solve the problems that the nitrite content is not easy to control, the sauerkraut is easy to become soft and rotten, and the content of miscellaneous bacteria is high, and achieves unique flavor, high content of non-volatile acid, and mature period of pickling. the effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of method of anhydrous vacuum purebred lactic acid bacteria pickled sauerkraut, is characterized in that being made of following steps:

[0027] (1) Clean vegetables: repair fresh cabbage into clean vegetables;

[0028] (2) Pickling: Apply 1.0g of salt to every 100g of cabbage, put one layer of clean vegetables and one layer of salt into a special pickling bag;

[0029] (3) Add lactic acid bacteria: add 1.5g of special lactic acid bacteria culture solution to the cabbage prepared in step (2), and spray evenly;

[0030] (4) Vacuum packaging: Use special vacuum equipment to vacuumize the pickled bag containing the processed cabbage;

[0031] (5) Fermentation and maturation: place the vacuum-pumped pickling bag containing cabbage in an environment of 10°C for 30 days to ferment to make sauerkraut.

[0032] The material of the special pickling bag in the above-mentioned step (2) requires an oxygen permeability rate lower than 1 / [cm 3 / (m 2 ·24h·0.1M...

Embodiment 2

[0035] Embodiment 2: a kind of method of anhydrous vacuum purebred lactic acid bacteria pickled sauerkraut, is characterized in that being made of following steps:

[0036] (1) Clean vegetables: repair fresh cabbage into clean vegetables;

[0037] (2) Pickling: apply 1.5g of salt to every 100g of cabbage, put one layer of clean vegetables and one layer of salt into a special pickling bag;

[0038] (3) Add lactic acid bacteria: add 1.0g of special lactic acid bacteria culture solution to the cabbage prepared in step (2), and spray evenly;

[0039] (4) Vacuum packaging: Use special vacuum equipment to vacuumize the pickled bag containing the processed cabbage;

[0040] (5) Fermentation and maturation: place the vacuum-pumped pickling bag containing cabbage in an environment of 15°C for 25 days to ferment to make sauerkraut.

[0041] The material of the special pickling bag in the above-mentioned step (2) requires an oxygen permeability rate lower than 1 / [cm 3 / (m 2 ·24h·0.1M...

Embodiment 3

[0044] Embodiment 3: a kind of method of anhydrous vacuum purebred lactic acid bacteria pickled sauerkraut, is characterized in that being made of following steps:

[0045] (1) Clean vegetables: repair fresh cabbage into clean vegetables;

[0046] (2) Pickling: apply 2.0g of salt to every 100g of cabbage, put one layer of clean vegetables and one layer of salt into a special pickling bag;

[0047] (3) Add lactic acid bacteria: add 0.5g of special lactic acid bacteria culture solution to the cabbage prepared in step (2), and spray evenly;

[0048] (4) Vacuum packaging: Use special vacuum equipment to vacuumize the pickled bag containing the processed cabbage;

[0049] (5) Fermentation and maturation: place the vacuum-pumped pickling bag containing cabbage in an environment of 20°C for 20 days to ferment to make sauerkraut.

[0050] The material of the special pickling bag in the above-mentioned step (2) requires an oxygen permeability rate lower than 1 / [cm 3 / (m 2 ·24h·0.1MP)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxygen permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com