Total unsaturated toad lactone, and preparation method and use thereof

A bufa lactone and unsaturated technology, applied in the field of natural medicinal chemistry, can solve problems such as cardiotoxicity, and achieve the effects of low cost, simple preparation method and good anti-prostate cancer activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

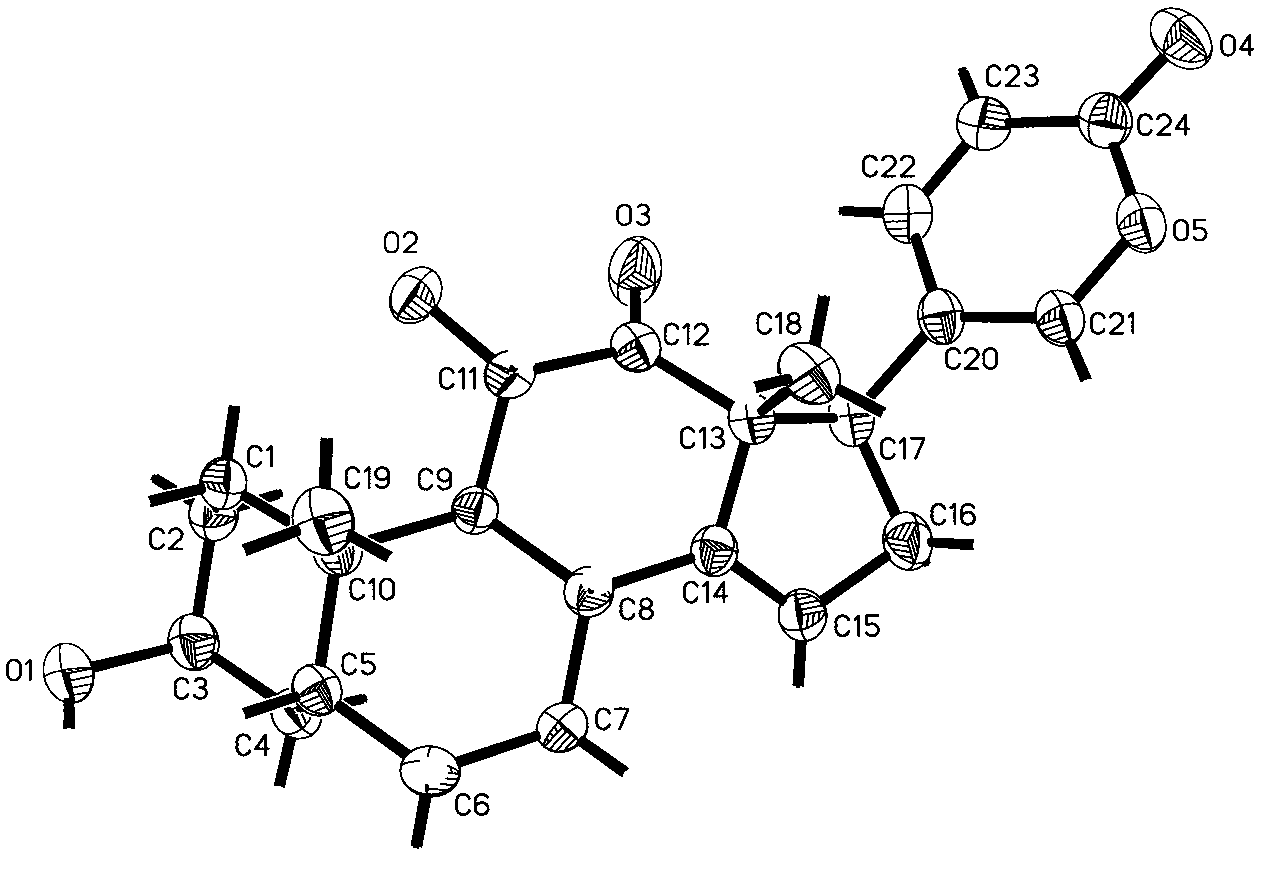

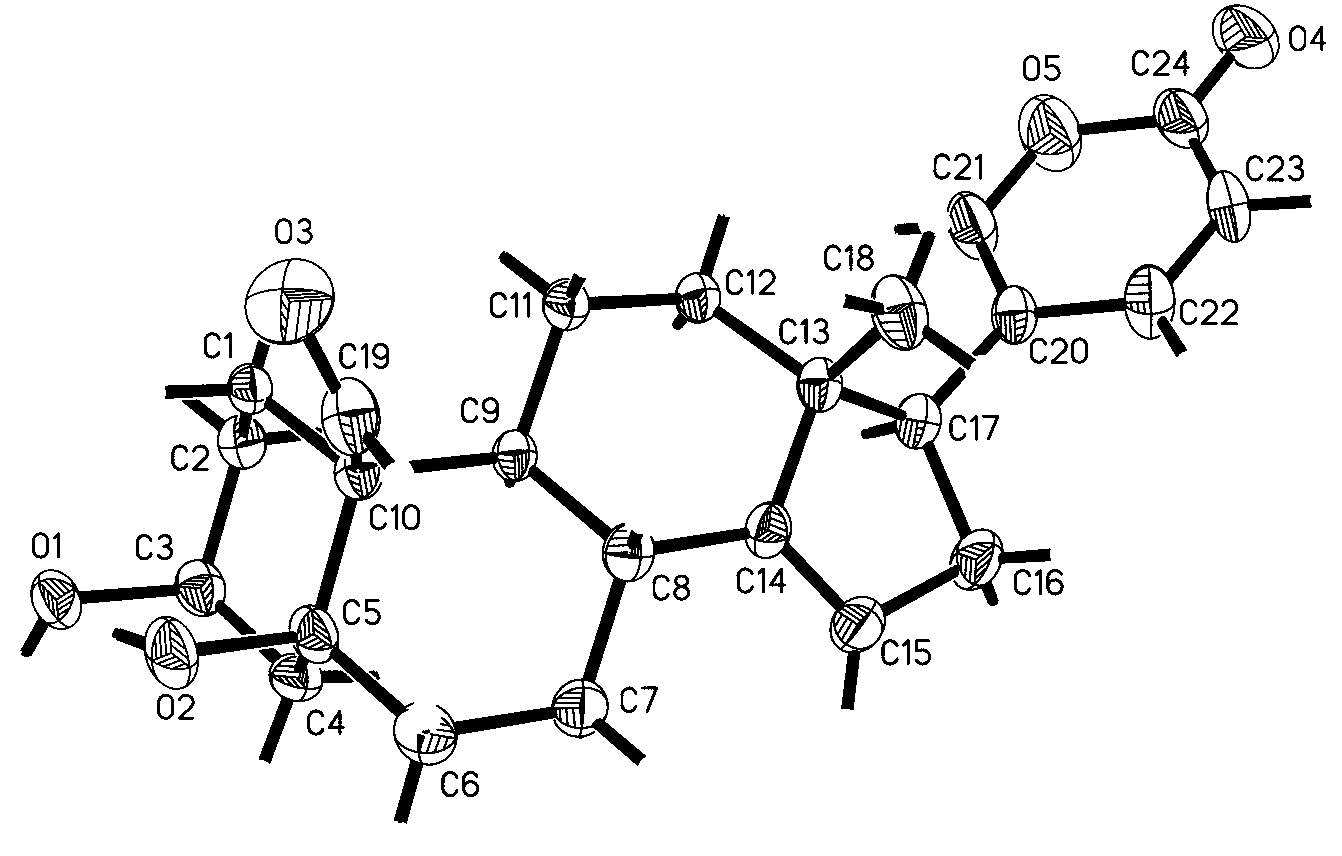

Image

Examples

Embodiment 1

[0047] (1) The preparation of total unsaturated bufalides comprises the following steps:

[0048] A. Grind 20g of dried Chansu (commercially available) with a stirrer, pass through a 100-mesh sieve, and extract 3 times with ethanol (absolute ethanol) with a volume percentage of 95% at room temperature through a KQ 250DE ultrasonic machine, each time using ethanol 100ml, each time for 1 hour, combine the three extracts, filter with filter paper to remove the residue, and obtain the toad venom extract.

[0049] B. Then use the N-1100V-W type rotary evaporator to concentrate the extract of toad venom under reduced pressure to form a slurry to obtain the total extract of toad venom.

[0050] C, suspending the total extract of Bufo venom with ultrapure water, extracting with 250ml dichloromethane, and removing dichloromethane under reduced pressure to obtain 12.2g of dichloromethane parts, which are total bufolides;

[0051] D. Dissolve the total bufolide obtained in step (3) with...

Embodiment 2

[0091] (1) The preparation of total unsaturated bufalides comprises the following steps:

[0092] A. Grind 20g of dried Chansu (commercially available) with a stirrer, pass through a 100-mesh sieve, and extract 3 times with ethanol (absolute ethanol) with a volume percentage of 95% at room temperature through a KQ 250DE ultrasonic machine, each time using ethanol 100ml, each time is 1 hour, combine the three extracts, filter with filter paper, to obtain the extract of Buad venom.

[0093] B. Then use the N-1100V-W type rotary evaporator to concentrate the extract of toad venom under reduced pressure to form a slurry to obtain the total extract of toad venom.

[0094] C, suspending the total extract of Bufo venom with ultrapure water, extracting with 200ml dichloromethane, and decompressing to remove dichloromethane to obtain 11.8g of dichloromethane parts, which are total bufolides;

[0095] D. Dissolve the total bufalide obtained in step (3) with 50ml of dichloromethane, add...

Embodiment 3

[0103] (1) The preparation of total unsaturated bufalides comprises the following steps:

[0104] A. Grind 20g of dried toad venom (commercially available) with a blender, pass through a 100-mesh sieve, and extract 3 times with 95% ethanol (absolute ethanol) at room temperature through a KQ 250DE ultrasonic machine, each time using ethanol 100ml, each time is 1 hour, combine the three extracts, filter with filter paper, to obtain the extract of Buad venom.

[0105] B. Then use the N-1100V-W type rotary evaporator to concentrate the extract of toad venom under reduced pressure to form a slurry to obtain the total extract of toad venom.

[0106] C, suspending the total extract of toad venom with ultra-pure water, extracting with 300ml dichloromethane, and decompressing to remove dichloromethane to obtain 12.8g of dichloromethane parts, which are total bufolides;

[0107] D. Dissolve the dichloromethane part obtained in step (3) with 50ml of dichloromethane, add 10% sulfuric aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com