Filling and sealing system and method of hollow fiber membrane modules

A fiber membrane and potting technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high energy consumption for packaging, waste of potting medium, low packaging efficiency, etc., and achieve high potting efficiency , promoting uniform distribution, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

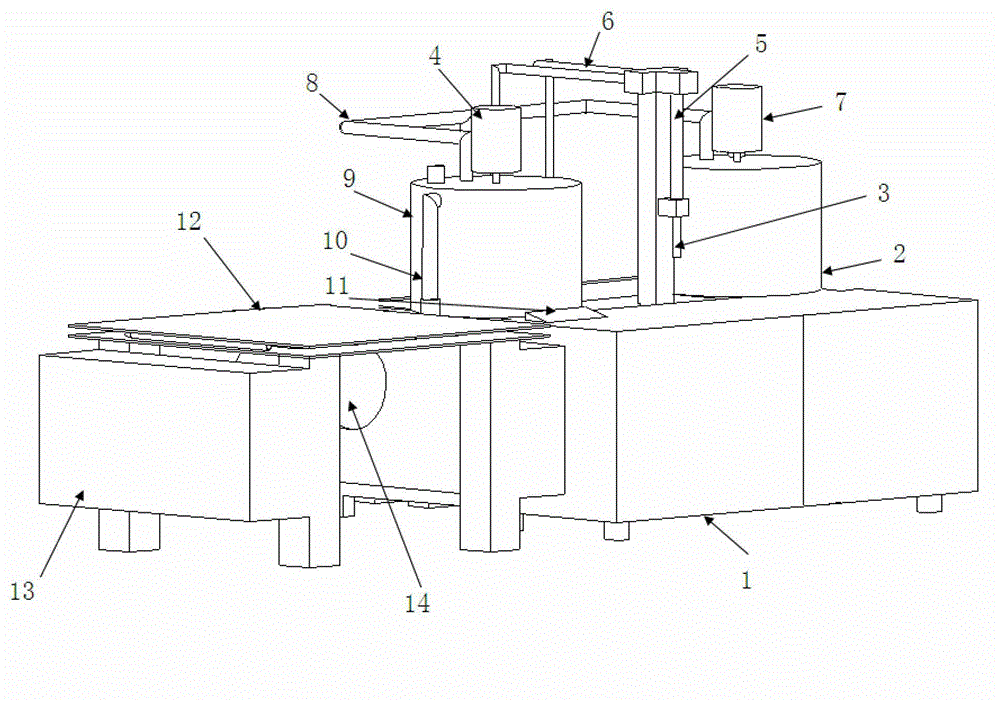

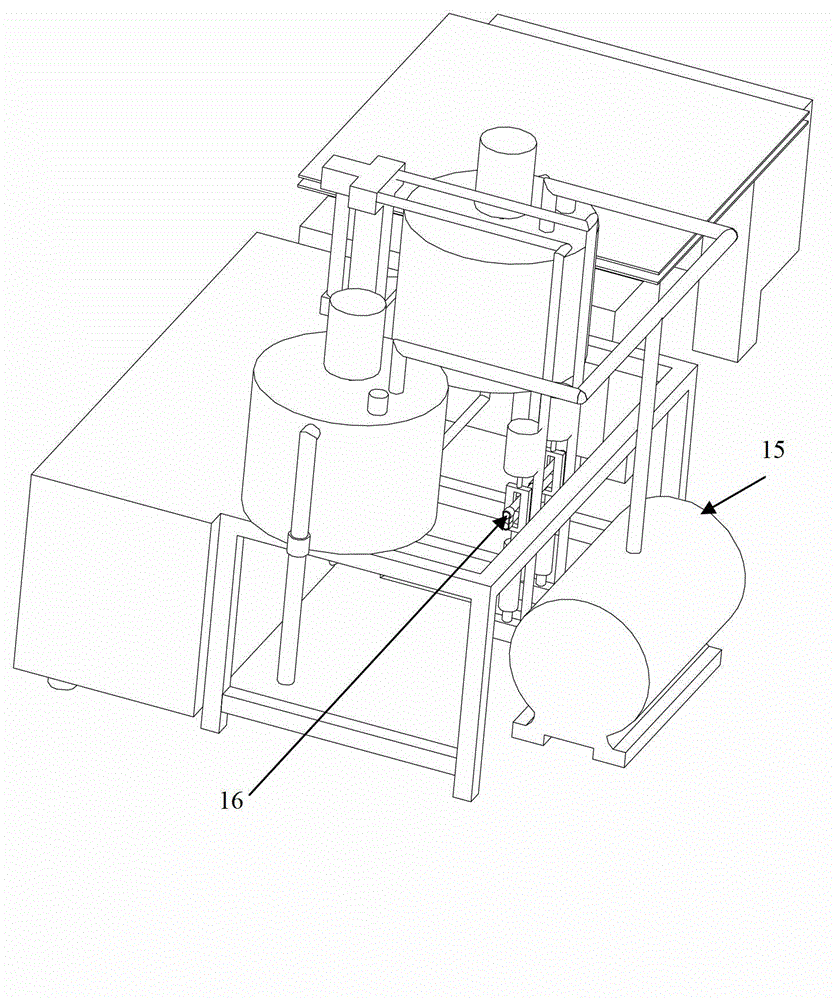

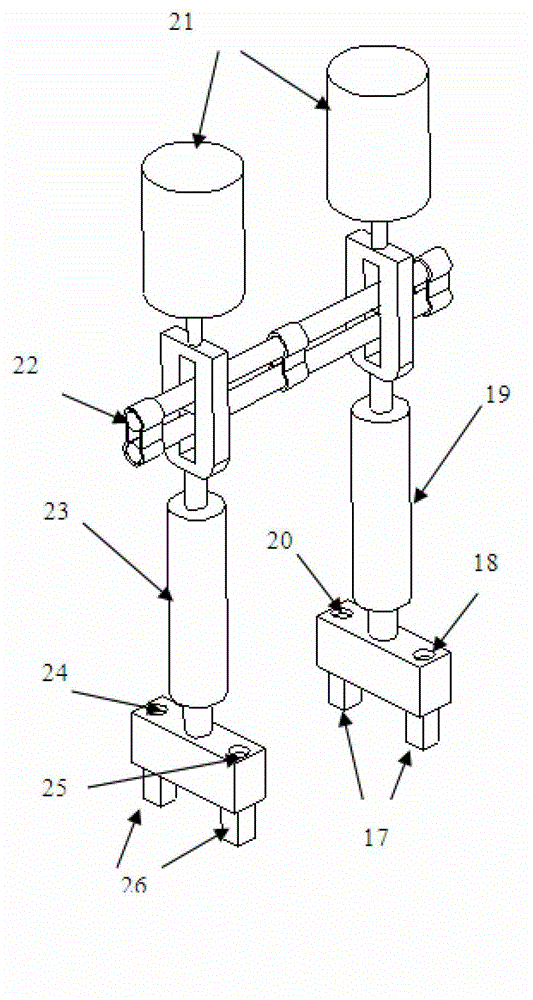

[0037] Such as figure 1 , figure 2 As shown, the hollow fiber membrane module potting system includes a PLC programmable control cabinet 1, and No. 1 potting medium tank 2 and No. 2 potting medium tank 9 arranged on one side of the PLC programmable control cabinet, wherein: 1 filling Sealing medium tanks No. 2 and No. 2 potting medium tanks 9 are fed through corresponding potting medium feed pipes 10, and No. 1 potting medium tank 2 and No. 2 potting medium tanks 9 pass through the pipelines at the bottom of each and the potting medium tanks respectively. The input port of the medium metering system 16 is connected, and the potting medium metering system 16 is connected with the static online mixer 5 through the potting medium pipe 6, and the static online mixer 5 is connected to the hollow fiber membrane module to be potted through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com