Chiral chromatographic stationary phase of polymer-coated silica and preparation method thereof

A chiral chromatography and polymer technology, applied in the field of material chemistry, can solve problems such as clogged injection port or column inlet, difficulty in reaching ideal concentration, poor solubility of inclusion complexes, etc., and achieves mild conditions and chiral separation effect Good, high column efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

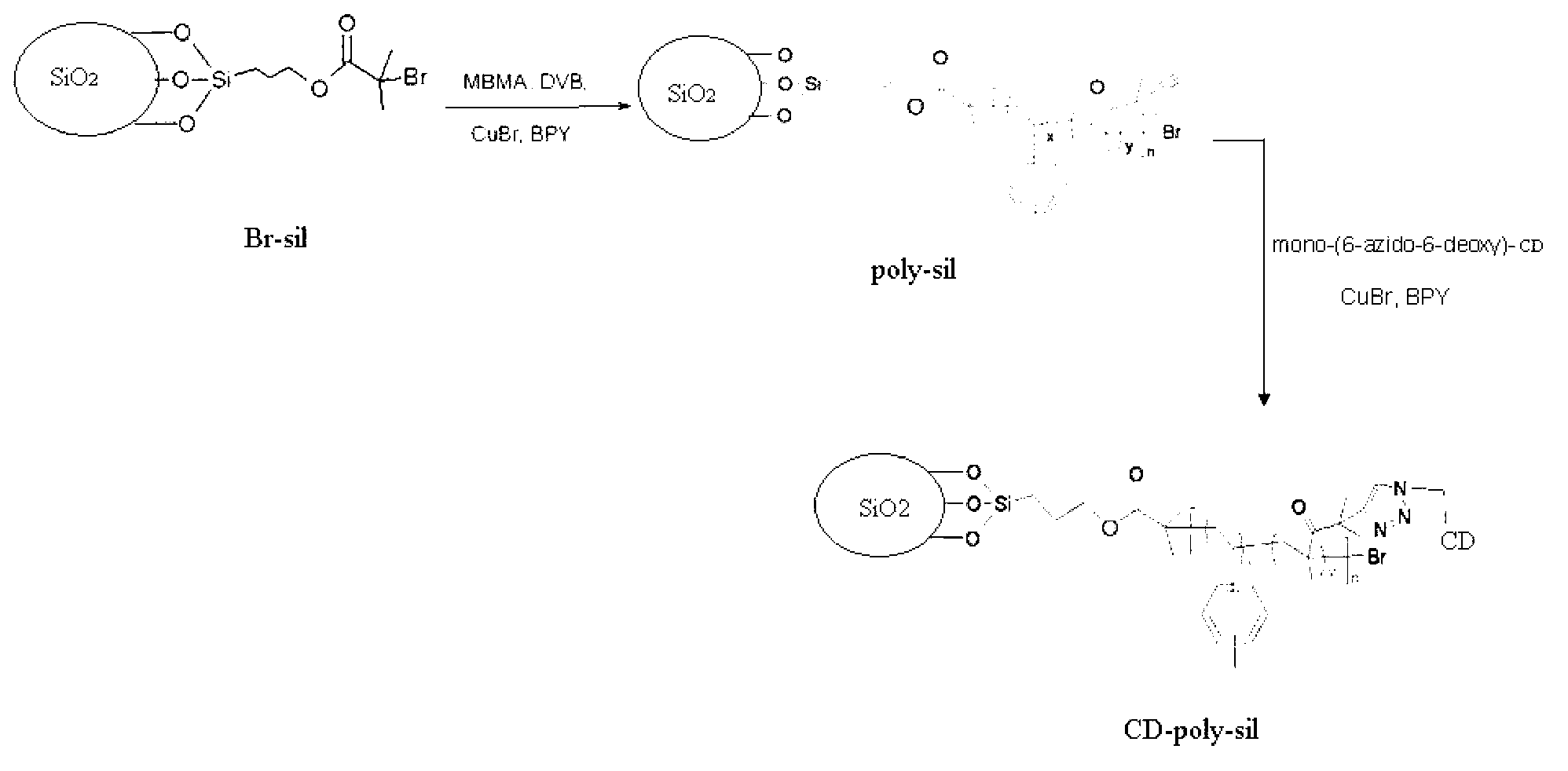

[0030] The preparation of the silica gel matrix of embodiment 1 coating polymer

[0031] Initiate the ATRP coated polymer layer on the surface of silica gel: take a round-bottomed three-necked flask, add successively 2.1 grams of silica gel with surface grafted ATRP initiator, 1.09 milliliters (7.18 mmol) of methyl butynyl methacrylate, and 1.00 ml of divinylbenzene milliliter (7.18mmol) and 30 milliliters of cyclohexanone, logical N 2 After 10 minutes, add 0.4475 grams (2.87mmol) of 2,2'-bipyridine and CuBr 0.2068 grams (1.44mmol), N 2 Under protection, react at 110°C for 4 hours. The density of bromine on the surface of silica gel is 0.9 micromole per square meter. After the reaction is completed, pour the reaction mixture suspension into absolute ethanol, stop the reaction, wash away the copper ions adsorbed on the surface of the silicon ball with saturated EDTA-2Na aqueous solution, then wash away the unreacted matter with acetone, and dry in vacuum , to obtain a polym...

Embodiment 2

[0032] The preparation of the silica gel matrix of embodiment 2 coating polymer

[0033] The difference from Example 1 is that the amount of each raw material is 2.1 grams of silica gel with surface-grafted ATRP initiator, 1.26 mmol of cuprous bromide, 2.31 mmol of 2,2'-bipyridine, and 6.3 mmol of methyl butynyl methacrylate. mmol, divinylbenzene 6.3 mmol. The polymerization time was 3 hours and the temperature was 105°C. Silicone matrices coated with polymers can likewise be produced.

Embodiment 3

[0034] The preparation of the silica gel matrix of embodiment 3 coating polymer

[0035] The difference from Example 1 is that the amount of each raw material is 2.1 grams of silica gel with surface-grafted ATRP initiator, 1.47 mmol of cuprous bromide, 3.15 mmol of 2,2'-bipyridine, and 8.4 grams of methyl butynyl methacrylate. mmol, divinylbenzene 8.4 mmol. The polymerization time was 5 hours and the temperature was 115°C. Silicone matrices coated with polymers can likewise be produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com