Rustproof repairing method for reinforced concrete structure

A technology of reinforced concrete and repair mortar, which is used in building maintenance, bridge maintenance, building construction, etc., can solve the problems of aging failure, reduced component toughness, easy to appear brittle fracture, etc., to improve the ability to work together, high interface viscosity. The effect of the knot strength and the guarantee of the bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

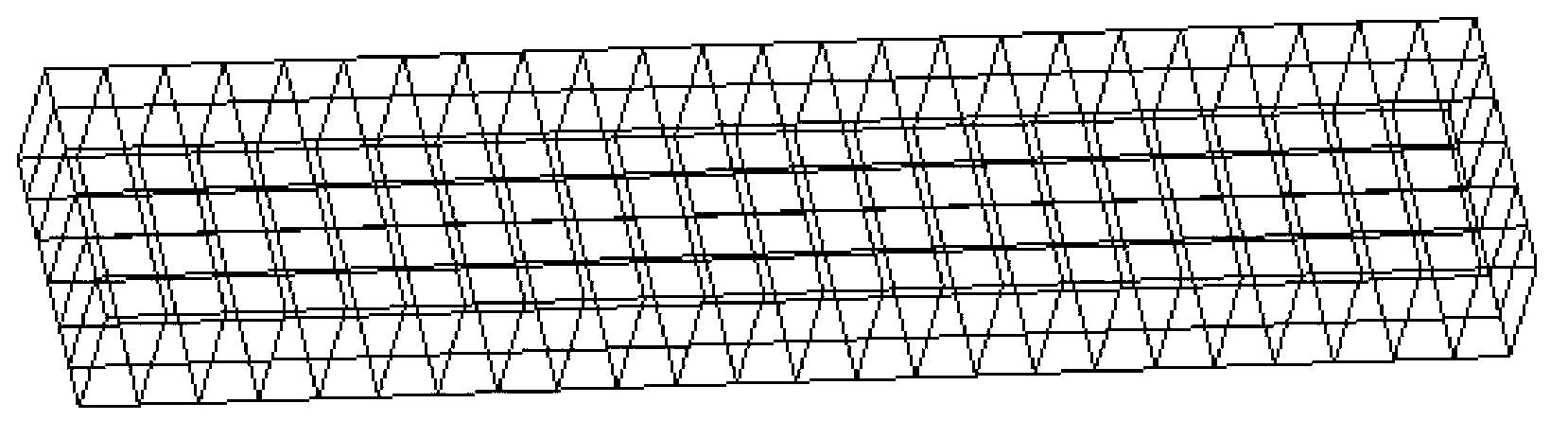

Image

Examples

Embodiment Construction

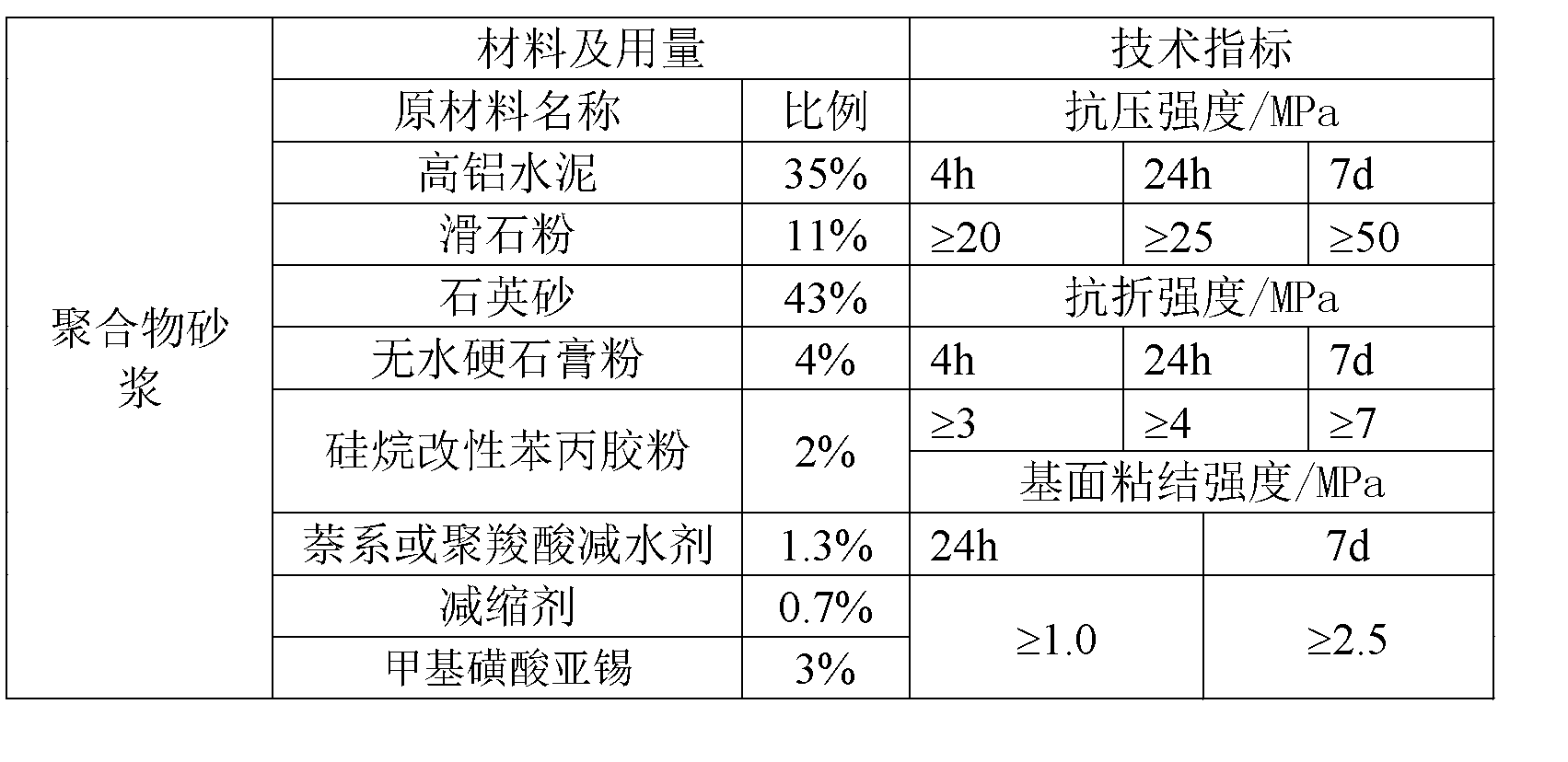

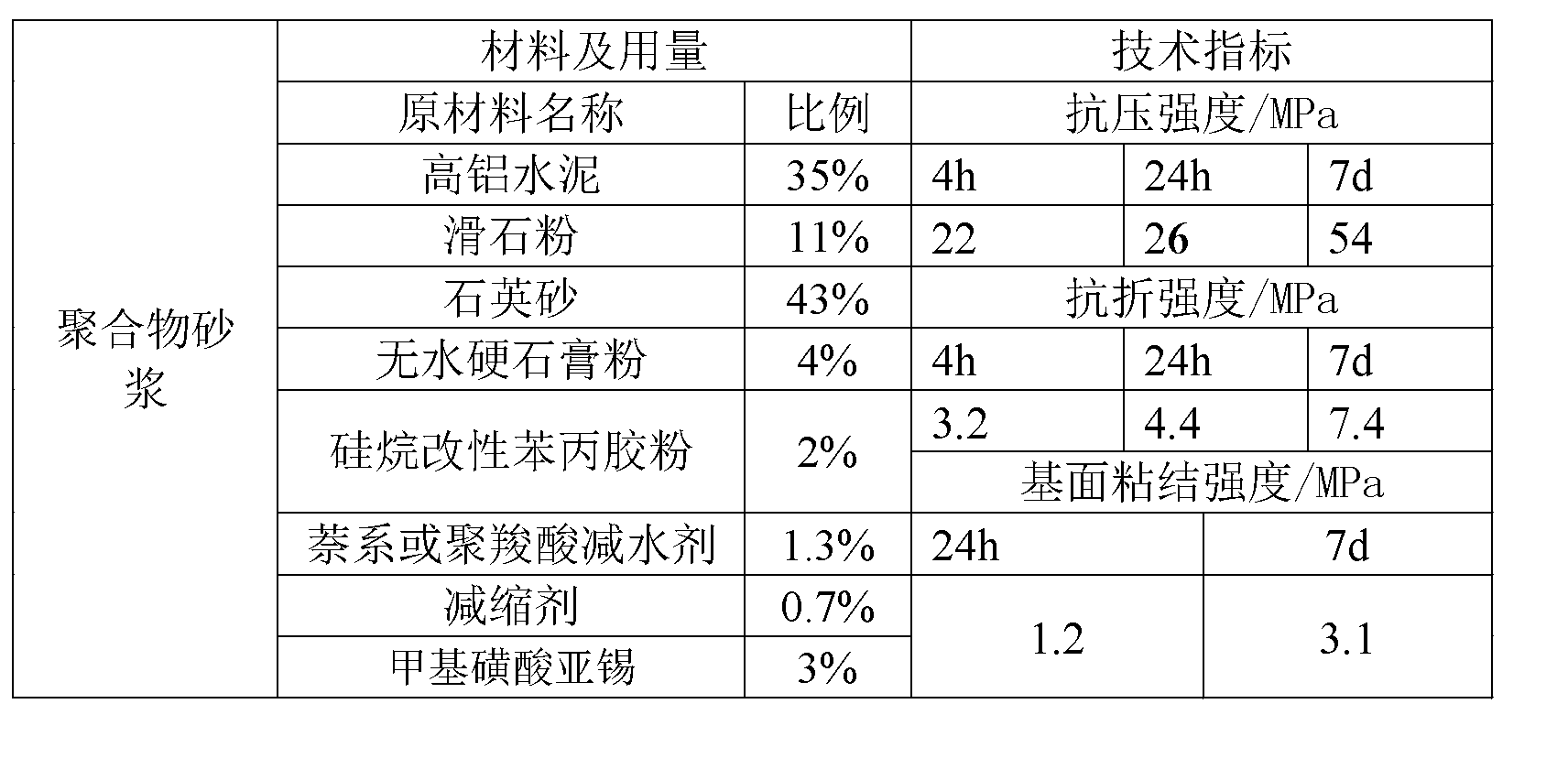

[0027] 1. The composition materials and properties of the polymer repair mortar in this embodiment are shown in Table 2, and the amount of water added when stirring the mortar is 14% of the mass of the repair mortar.

[0028] Table 2 Composition and performance of polymer repair mortar

[0029]

[0030] 2. There are three types of crack width repair methods for components:

[0031] 2.1 The crack width of member 1 is less than 0.5mm:

[0032] Chisel away the damaged concrete to expose the steel bar at one end. Clean the surface with high pressure water to remove debris, dust from the concrete surface. Use the interface agent emulsion, roll it on the surface of the component with a roller, brush the damaged part with a small brush, and carry out the next repairing construction after 2-4 hours of curing.

[0033] The surface is closed with 5mm thick polymer repair mortar. After the component damage and cracks are repaired, connect one end of the aluminum wire to the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com